Construction method of whole reverse replacement of structure

A construction method and integrated technology, applied in building construction, building maintenance, construction, etc., can solve the problems of large lateral unloading of external walls, large cantilever length of external walls, wall damage, etc. The effect of reducing the length of the wall cantilever, reducing the amount of single unloading, and shortening the time difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

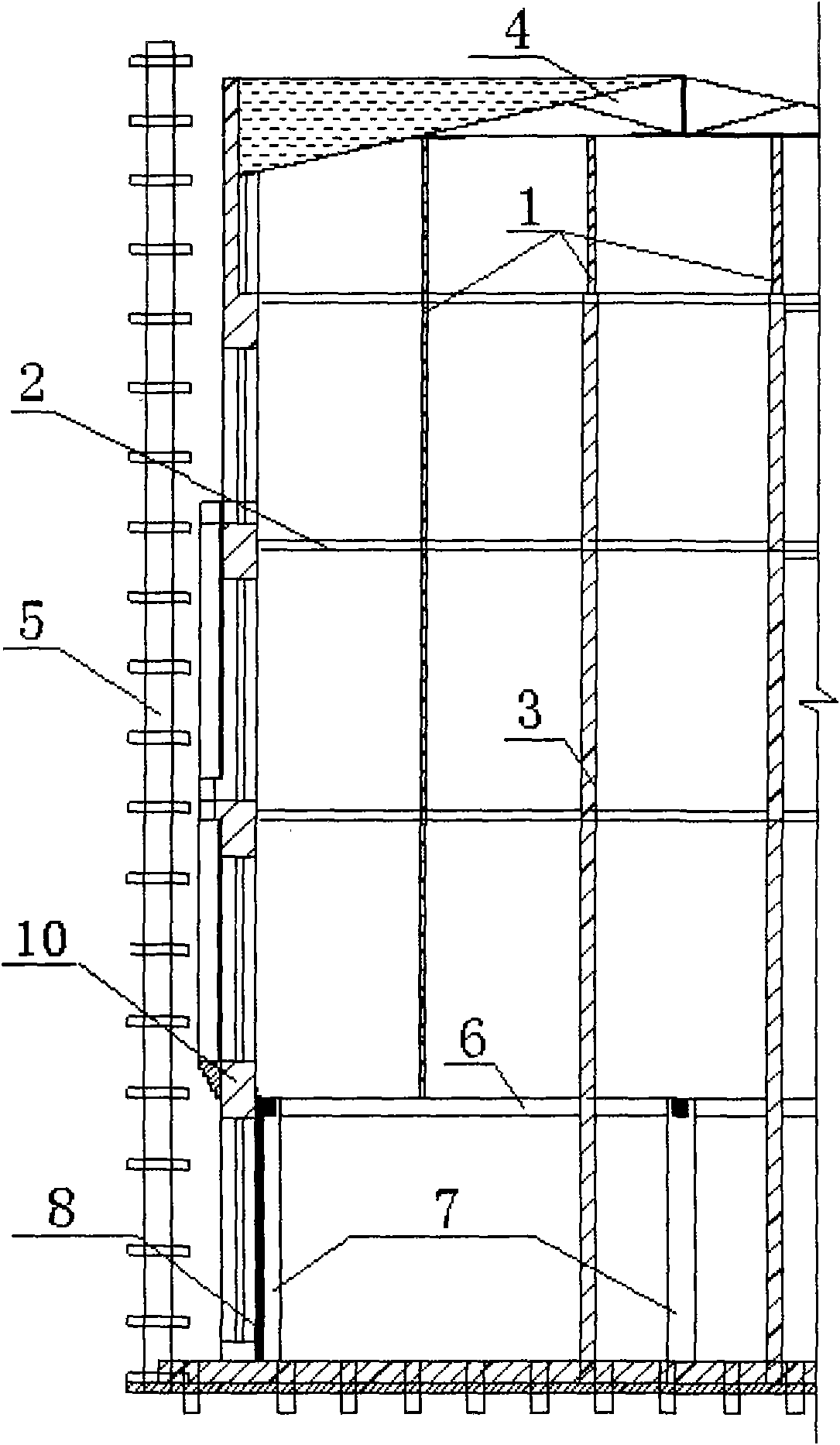

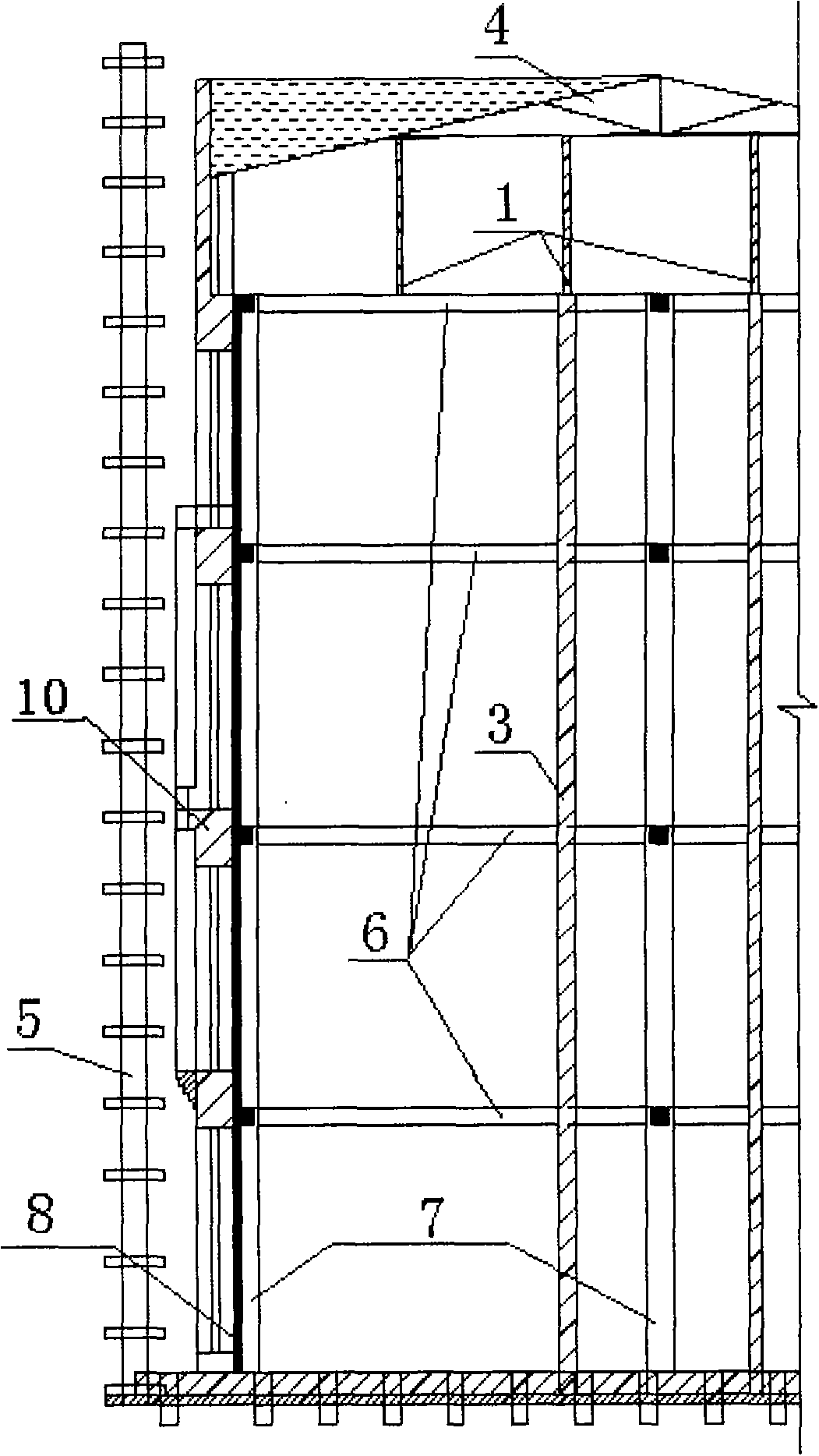

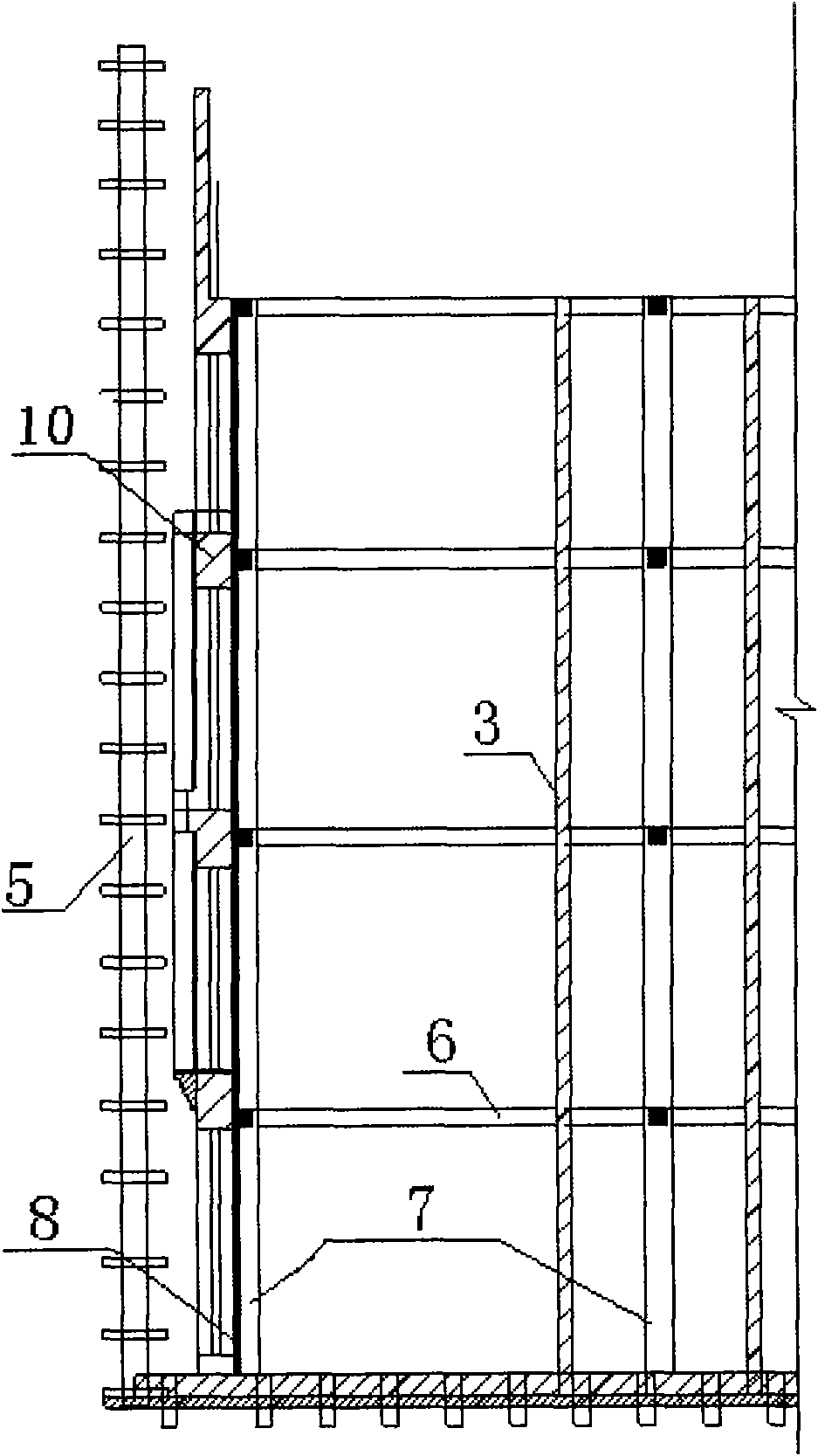

[0019] Below in conjunction with accompanying drawing and with the five-layer structure containing roof renovation project is example to further illustrate the invention construction method.

[0020] As shown in Fig. 1, the construction method for reverse replacement of the whole structure of the present invention comprises the following steps:

[0021] (1), if Figure 1a As shown, first construct the first floor: demolish the first layer of decorative layers, remove the original floor 2 of the second floor, and temporarily retain the original beams, load-bearing columns 1 and original inner walls 3 on the upper floor;

[0022] (2), set up the bent frame to the bottom of the lower beam of the original floor slab on the second floor, and carry out the construction of the outer wall reinforcement layer 8 of the first floor and the new frame column 7 of this floor at the same time;

[0023] (3) Remove the original second-floor beams, set up formwork, bind steel bars, and pour ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com