Efficient scroll compressor

A scroll compressor, high-efficiency technology, applied in the field of compressors to achieve the effects of low suction superheat, low cost, and reduced operating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

[0018] The engagement structure of the moving disk and the static disk of the scroll compressor in the prior art in the accompanying drawings is represented by symbols as follows:

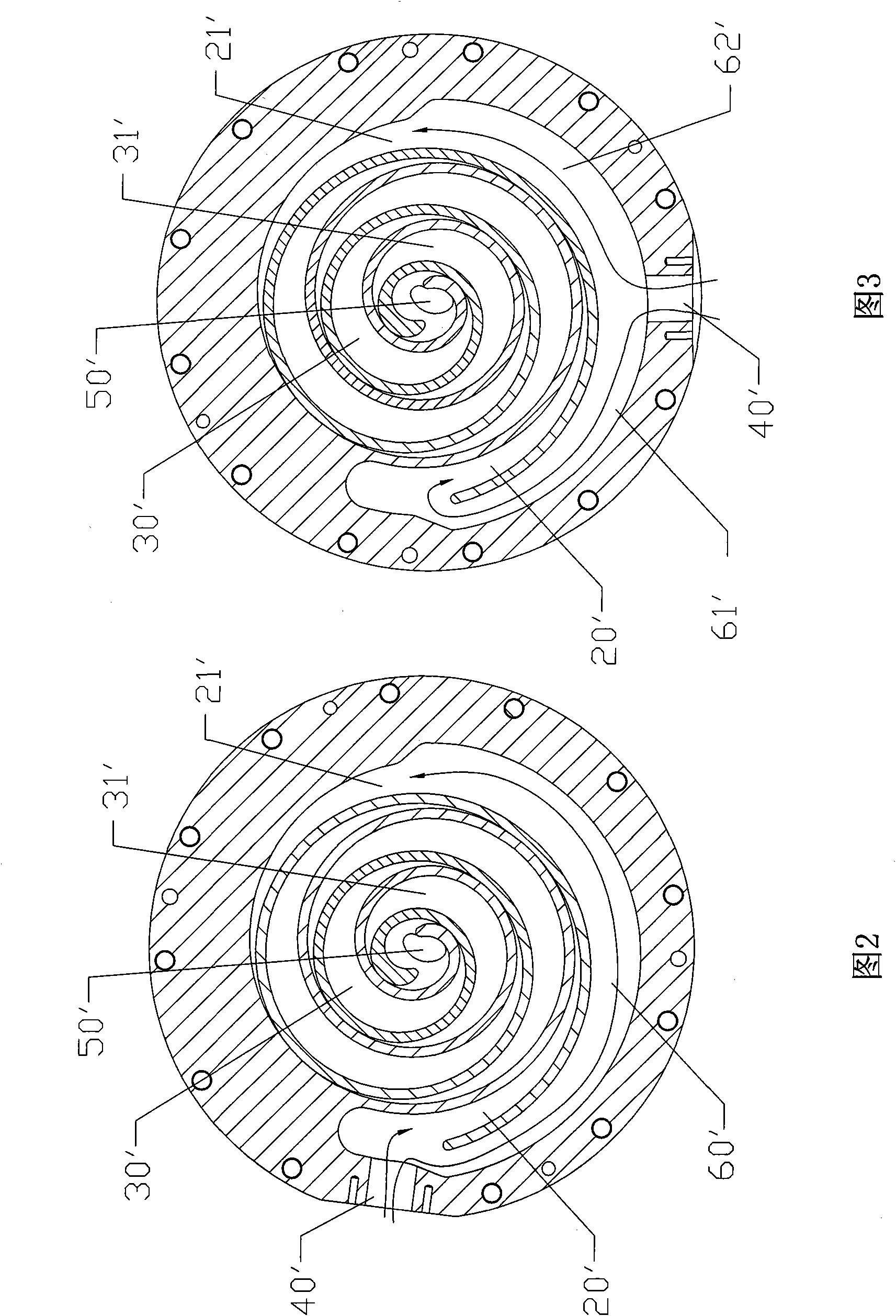

[0019] Suction inner chamber 20' Suction outer chamber 21' Compression inner chamber 30'

[0020] Compression outer chamber 31' Suction port 40' Exhaust chamber 50'

[0021] Inspiratory flow channels 60', 61', 62'

[0022] In the accompanying drawings, the components of the scroll compressor of the present invention are represented by labels as follows:

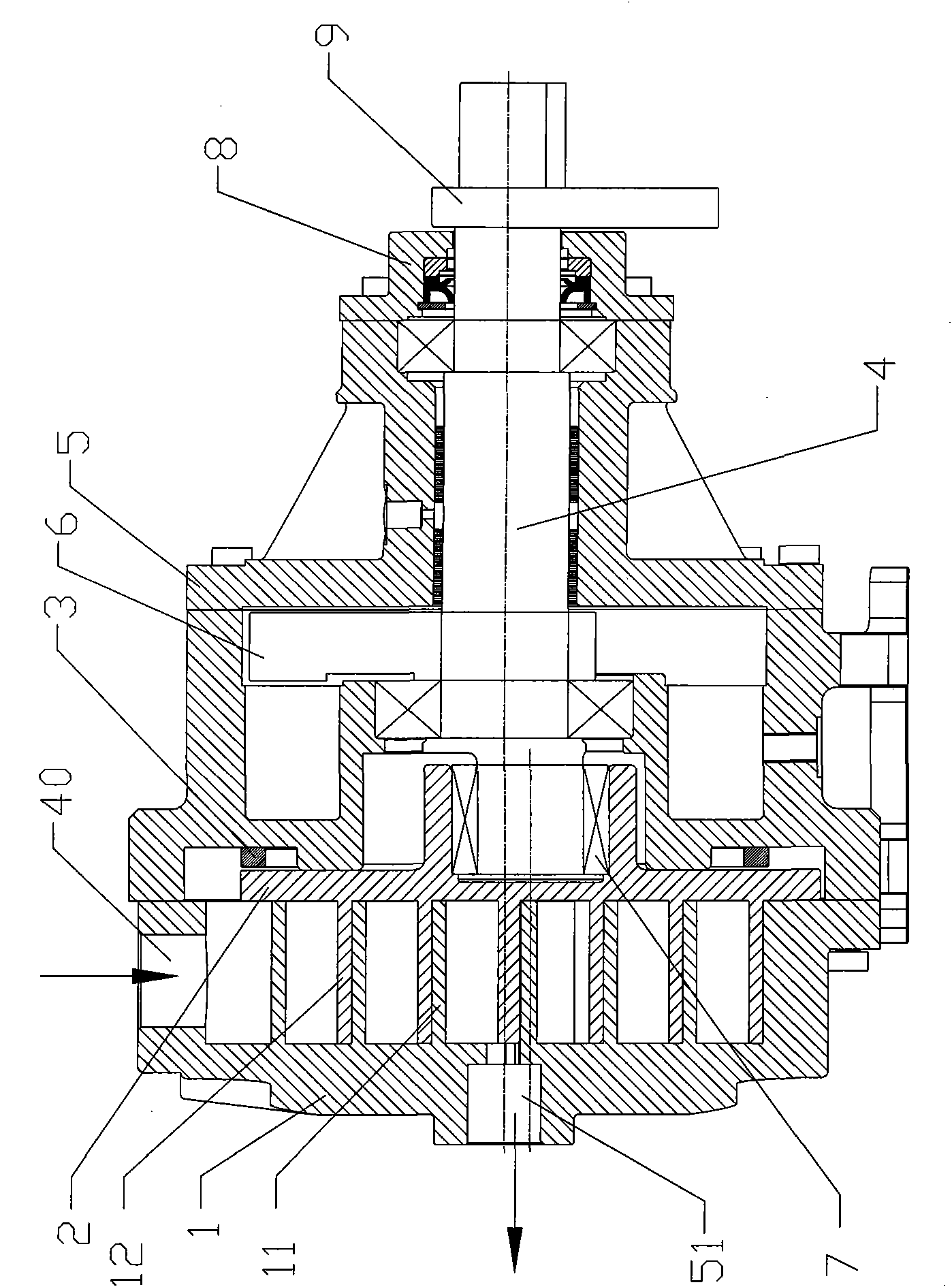

[0023] Static disk 1 Moving disk 2 Oldham ring 3 Crankshaft 4

[0024] Frame 5 main balance weight 6 bearing 7 rear cover 8

[0025] Auxiliary balance weight 9 Static disk scroll piece 11 Moving disk scroll piece 12

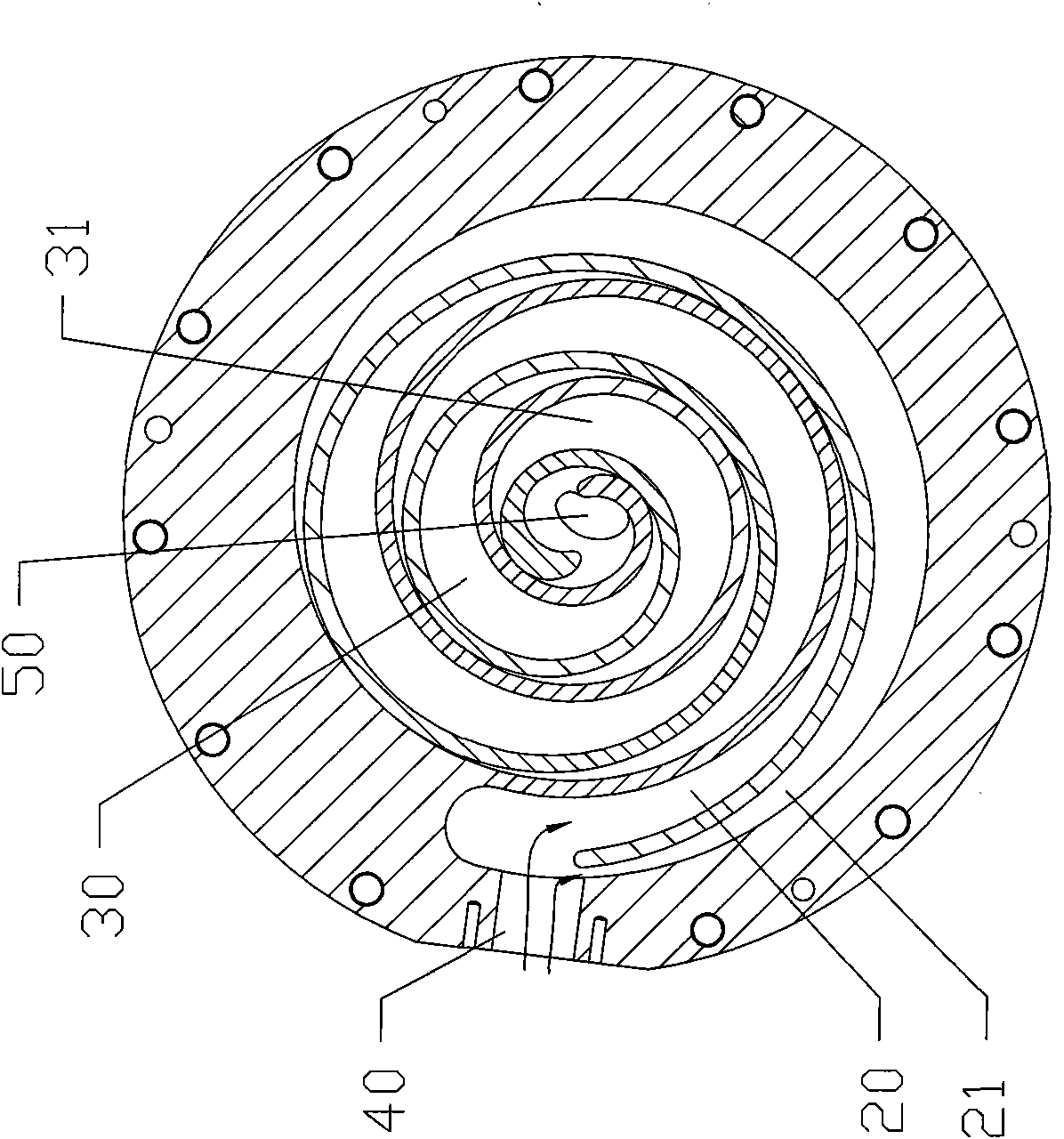

[0026] Suction inner chamber 20 Suction outer chamber 21 Compression inner chamber 30

[0027] Compression outer chamber 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com