Tube type heat exchanger on-line antiscale and reinforcing heat exchange device

A tube-and-tube heat exchanger and heat-enhancing technology, applied in the direction of cleaning heat-transfer devices, heat-transfer modification, heat-exchange equipment, etc. The effect of winding, strengthening heat exchange, and consistent speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

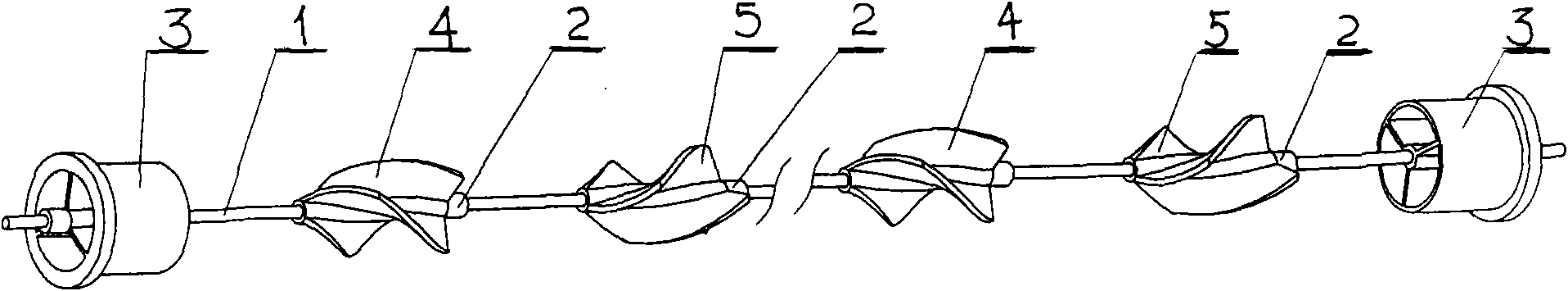

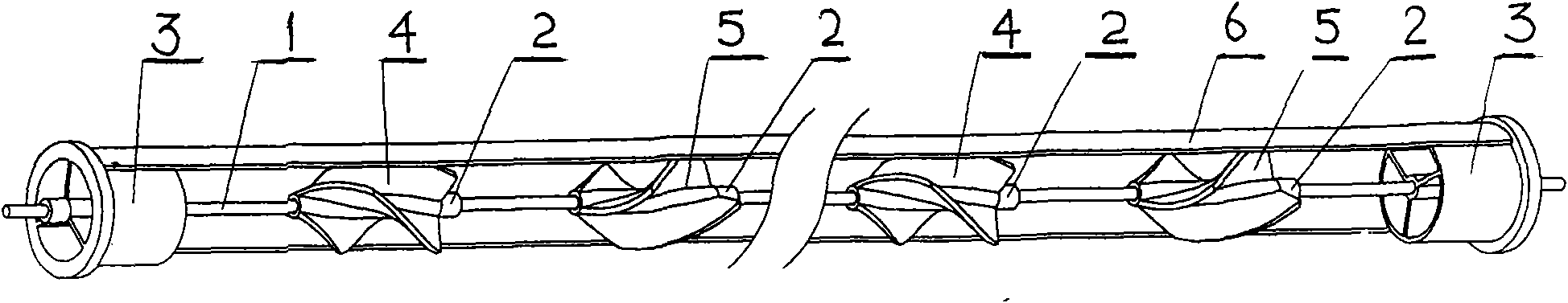

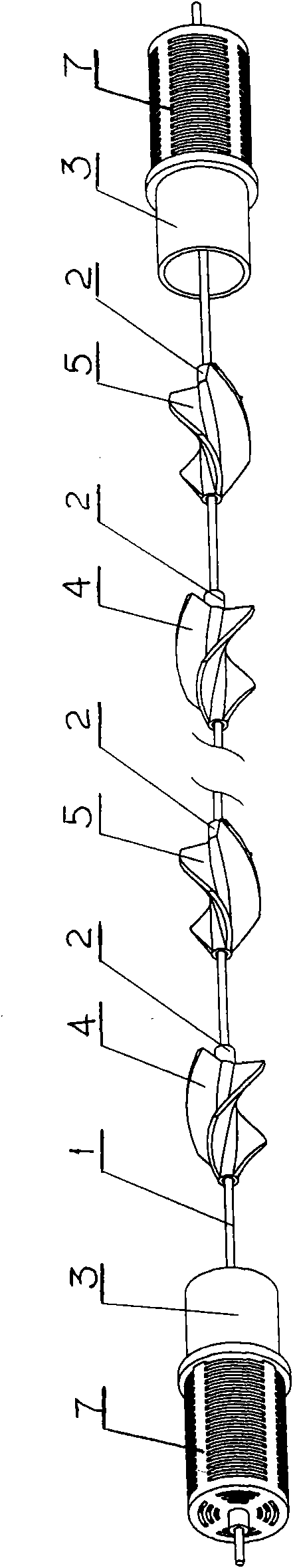

[0031] Depend on Figure 1-Figure 16 It can be seen that the two ends of the tensioned stainless steel rope 1 of the present invention are equipped with fixing frames 3 respectively fixed on both ends of the heat exchange tube 6, and the stainless steel rope 1 is fixed with the limit sleeves 2 at equal intervals, which are located at the front end of each limit sleeve 2 The impellers 4 and 5 of positive and negative rotations are installed in sequence on the stainless steel rope 1.

[0032] The impellers 4 and 5 are single blades, double blades or three blades.

[0033] The impellers 4, 5 are hollow or solid.

[0034] The water-facing sides of the impellers 4 and 5 are provided with chamfers.

[0035] The front end of the fixing frame 3 is provided with a filter cover 7 .

[0036] When the present invention is installed in the heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com