Series connection stroke increment type electric automobile high-voltage electricity quick-discharge control method

A technology of electric vehicles and control methods, which is applied to electric vehicles, electrical devices, vehicle components, etc., and can solve problems such as motor rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

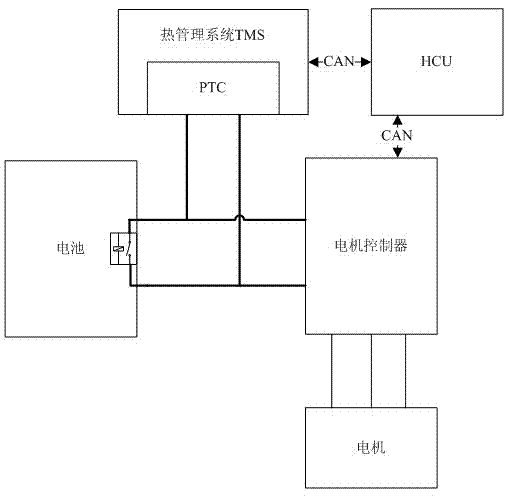

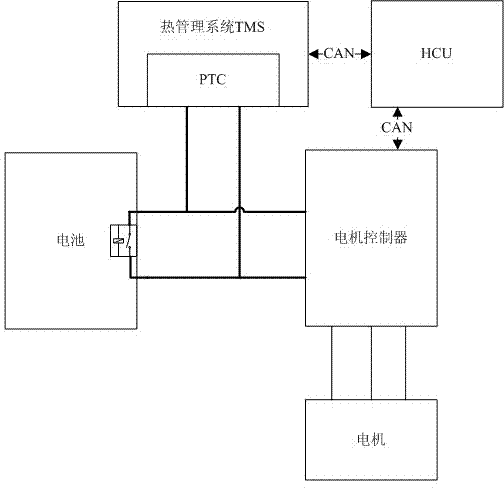

[0023] The structure diagram of the high-voltage parts of the present invention is as follows figure 1 As shown: the battery is an energy storage device, there is no capacitor inside, the motor and PTC work must take energy from the battery, and the high-voltage power-on completes the energy output through the closing of the relay; the motor controller has a capacitor inside, and the battery is connected to the relay after the relay is connected. The motor controller is connected through a DC high-voltage harness, and the high voltage of the battery is consistent with the capacitor voltage of the motor controller; the motor controller and the motor are connected through a three-phase high-voltage harness; the PTC and the battery are also connected through a DC high-voltage harness, and the thermal management system TMS controls the switch; the vehicle The controller HCU is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com