Steam heating type drink preparation device

The technology of a beverage preparation device and a steam generating device, which is applied in the field of steam-heated beverage preparation devices, can solve the problems of water deterioration, increasing the overall size of the product, and blockage of water supply pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

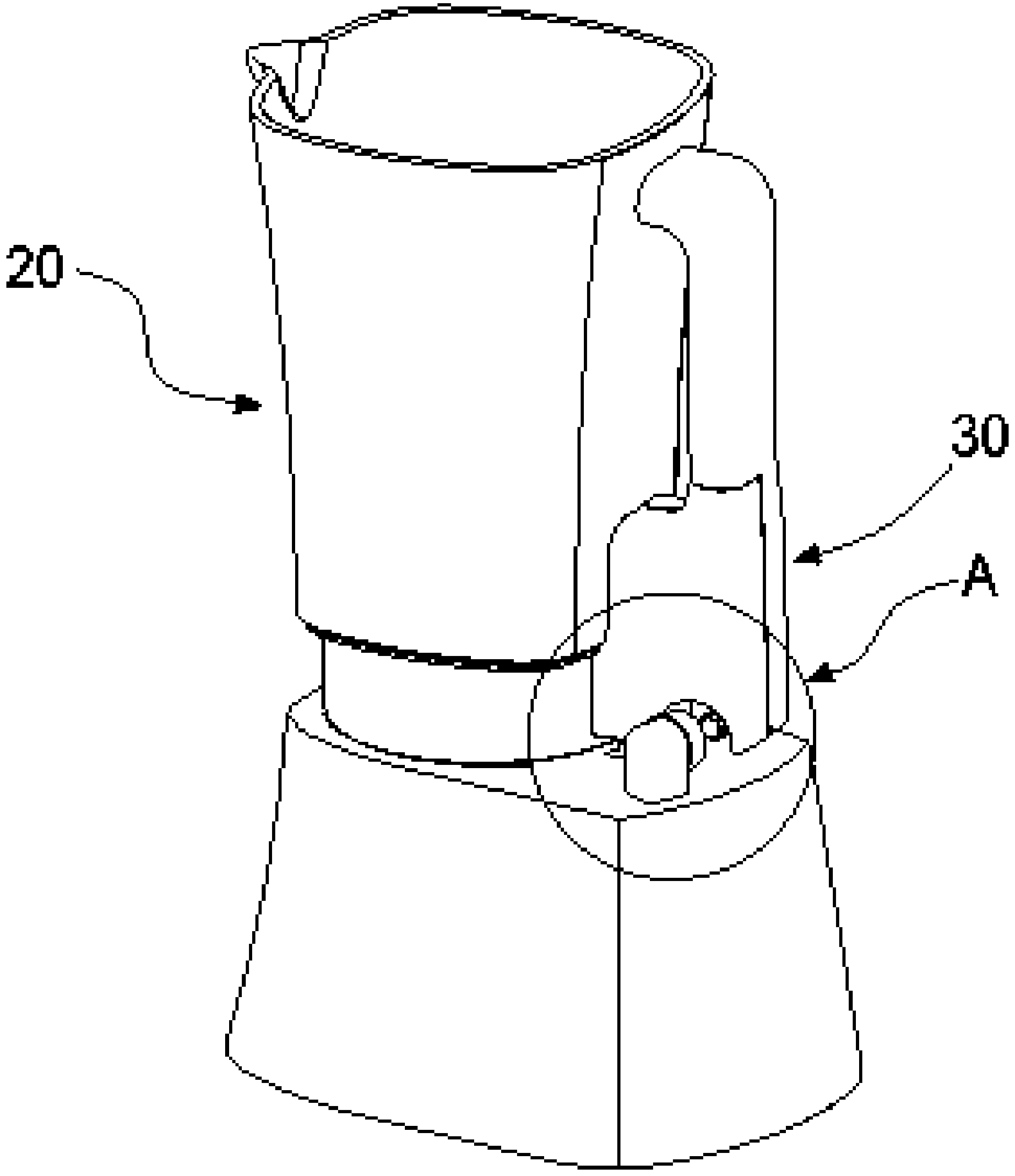

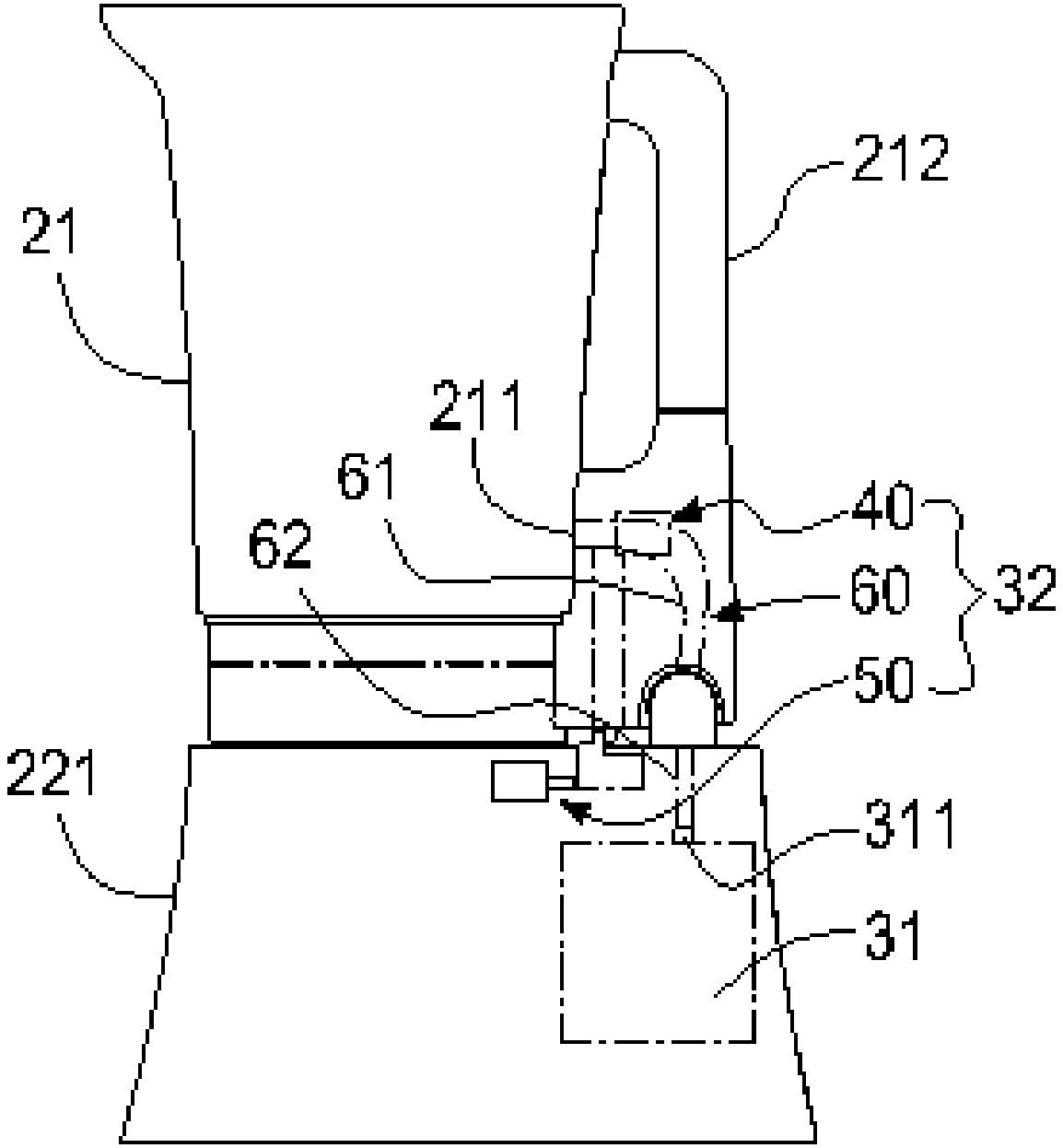

[0052] Such as figure 1 As shown, the steam heating beverage preparation device of the present invention includes a beverage preparation system 20 , a steam heating system 30 and a one-way water supply device 32 .

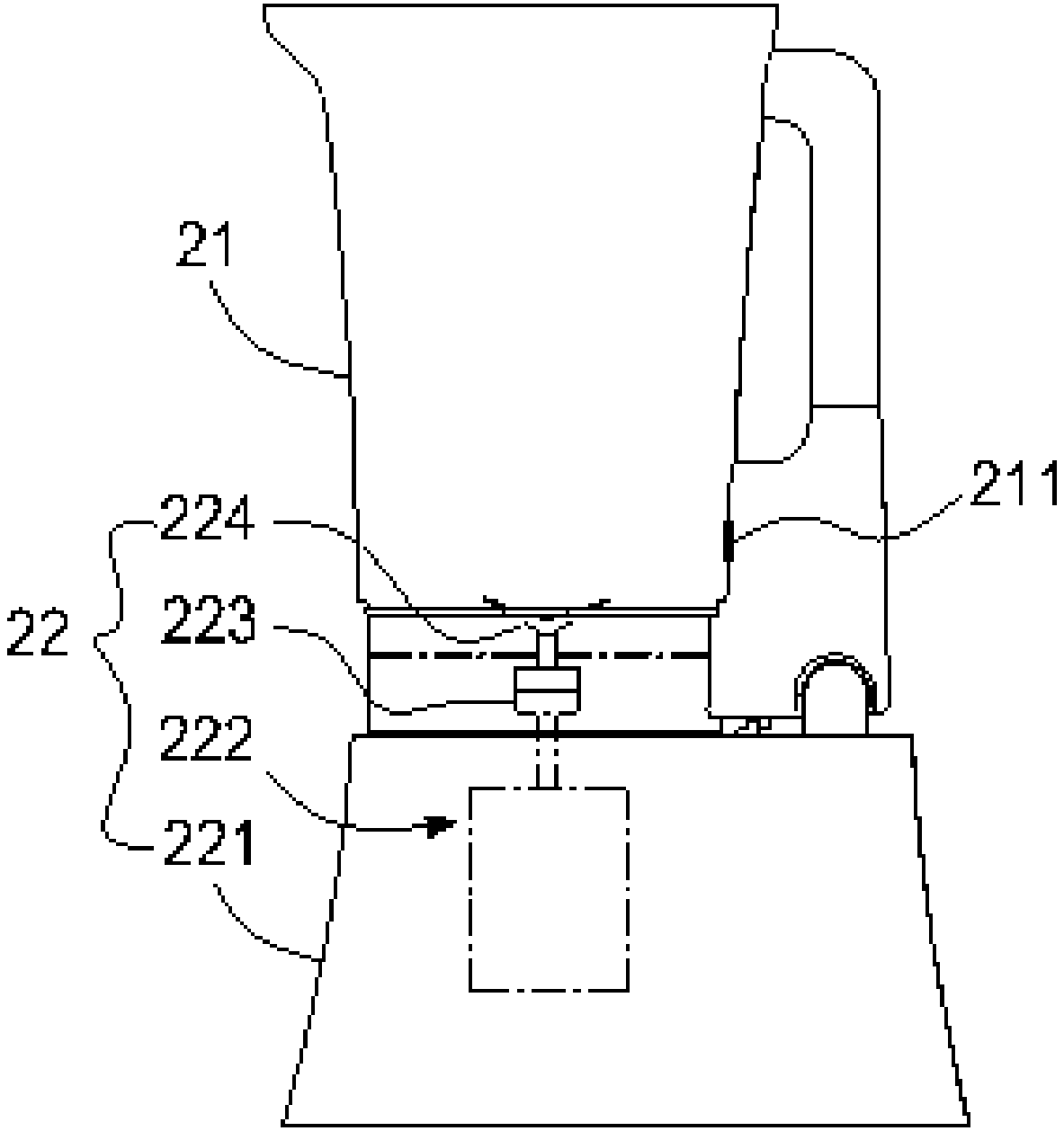

[0053] Such as figure 2 As shown, the beverage making system 20 includes: a beverage container 21 , and a beverage making device 22 for making a beverage in the beverage container 21 . The beverage container 21 is provided with a water outlet 211 . Beverage making device 22 both can adopt motor to be arranged on the top of the beverage container, crushing cutter or stirrer stretches into the beverage container from the opening above the beverage container to realize the machine head type device of beverage making, also can adopt such as figure 2 Shown is the undermounted motor.

[0054] figure 2 As shown, the beverage making device 22 includes: a base 221, a second power mechanism 222 disposed in the base 221, a knife holder 223 arranged at the bottom of th...

Embodiment approach 2

[0068] The main difference between this embodiment and Embodiment 1 lies in the water supply valve and the transmission mechanism.

[0069] Such as Figure 9 , Figure 10As shown, similar to the water supply valve 40 in Embodiment 1, the water supply valve 40' also includes: a connecting pipe 41' sealed to the water outlet 211, and a connecting pipe 41' arranged in the connecting pipe 41' and sealed with the water outlet 211. The matched piston rod 42 ′ communicates with the water supply pipe 60 through the connecting pipe 41 ′.

[0070] Wherein, the first end 421' of the piston rod 42' is a sealing plug, and the connecting pipe 41' or the water outlet 211 is provided with a sealing surface 411' matched with the sealing plug. Specifically, the sealing plug of the piston rod 42' is in the shape of Conical, the sealing surface is a hammer-shaped surface. The sealing plug and the sealing surface can be set to open the water outlet when the piston rod moves to the right, or can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com