Dumper

A technology for dump trucks and carriages, applied in the field of vehicles, which can solve problems such as potential safety hazards, unbalanced loads on the vehicle body, and offset of the center of gravity, etc., and achieve the effects of good safety performance, avoiding potential safety hazards, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

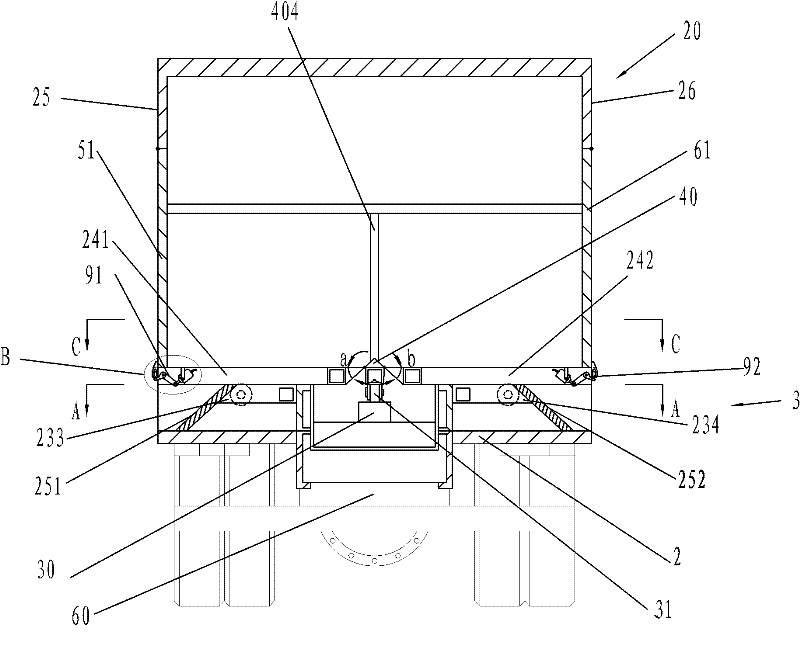

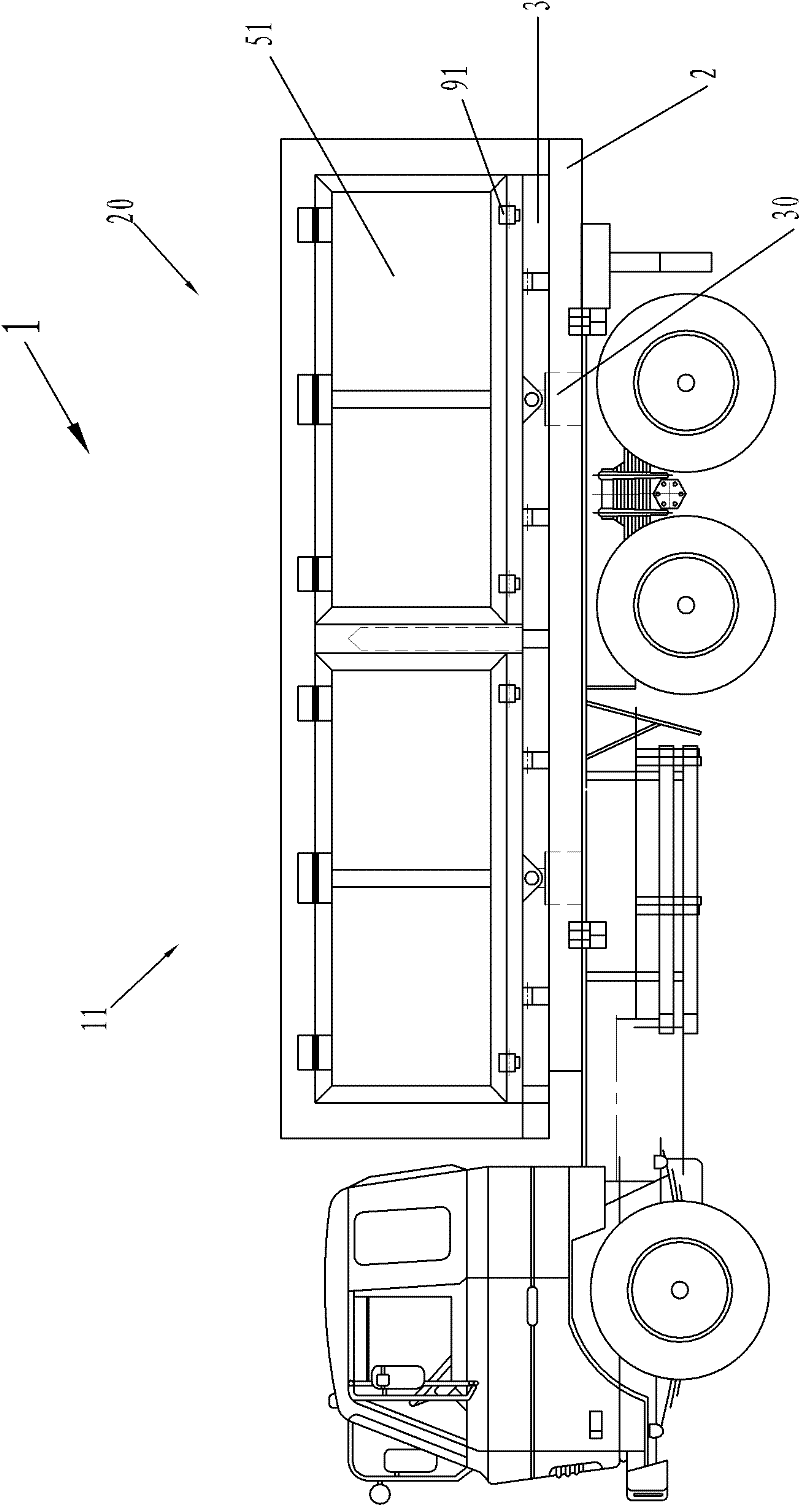

[0026] Such as figure 1 , figure 2 , image 3 As shown, the dump truck of the present invention includes a chassis 60 , a bucket 1 and a main frame 2 fixed on the chassis 60 . The car bucket 1 includes two independent compartments 11, 20, and the number of compartments can also be one, three or four, and the shape and structure of all compartments are exactly the same.

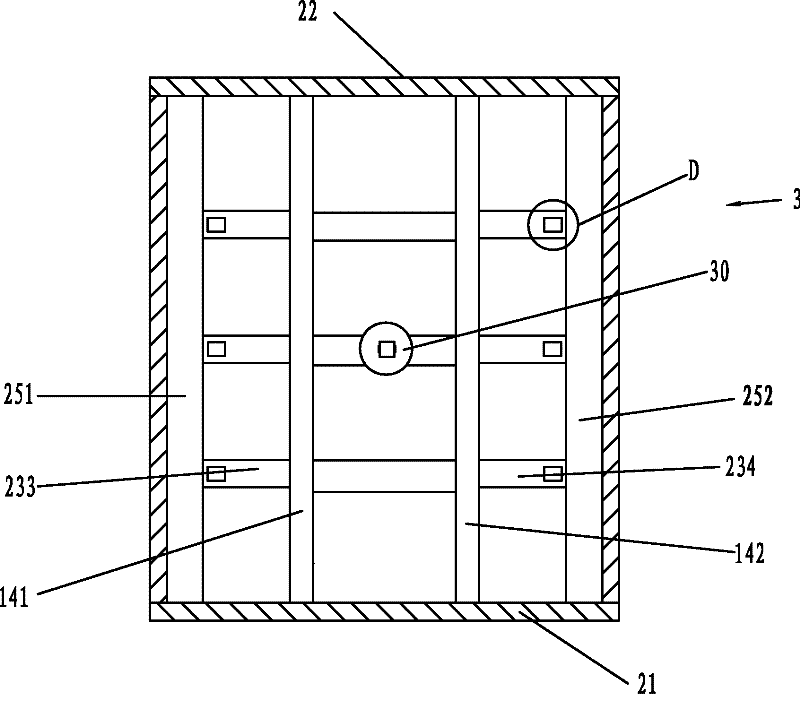

[0027] The first compartment 20 includes a left bottom panel 241 , a right bottom panel 242 , a left side panel 25 , a right side panel 26 , a front side panel 21 and a rear side panel 22 . There is a left door 51 on the left side plate 25 , and a right door 61 on the right side plate 26 . The front side plate 21 and the rear side plate are all welded on the main vehicle frame 2 . Both the left bottom plate 241 and the right bottom plate 242 are hollow steel plates.

[0028] The auxiliary frame 3 is installed between the main frame 2 and the left and right bottom plates 241 , 242 . Both the left and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com