Energy-dissipating element and impact protection with an energy-dissipating element

A technology of energy dissipation and shock absorber, which is applied in the direction of elastic shock absorber, transportation and packaging, buffer, etc., can solve the problem of no transmission support structure for impact force, achieve low longitudinal shortening, and reduce the required space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

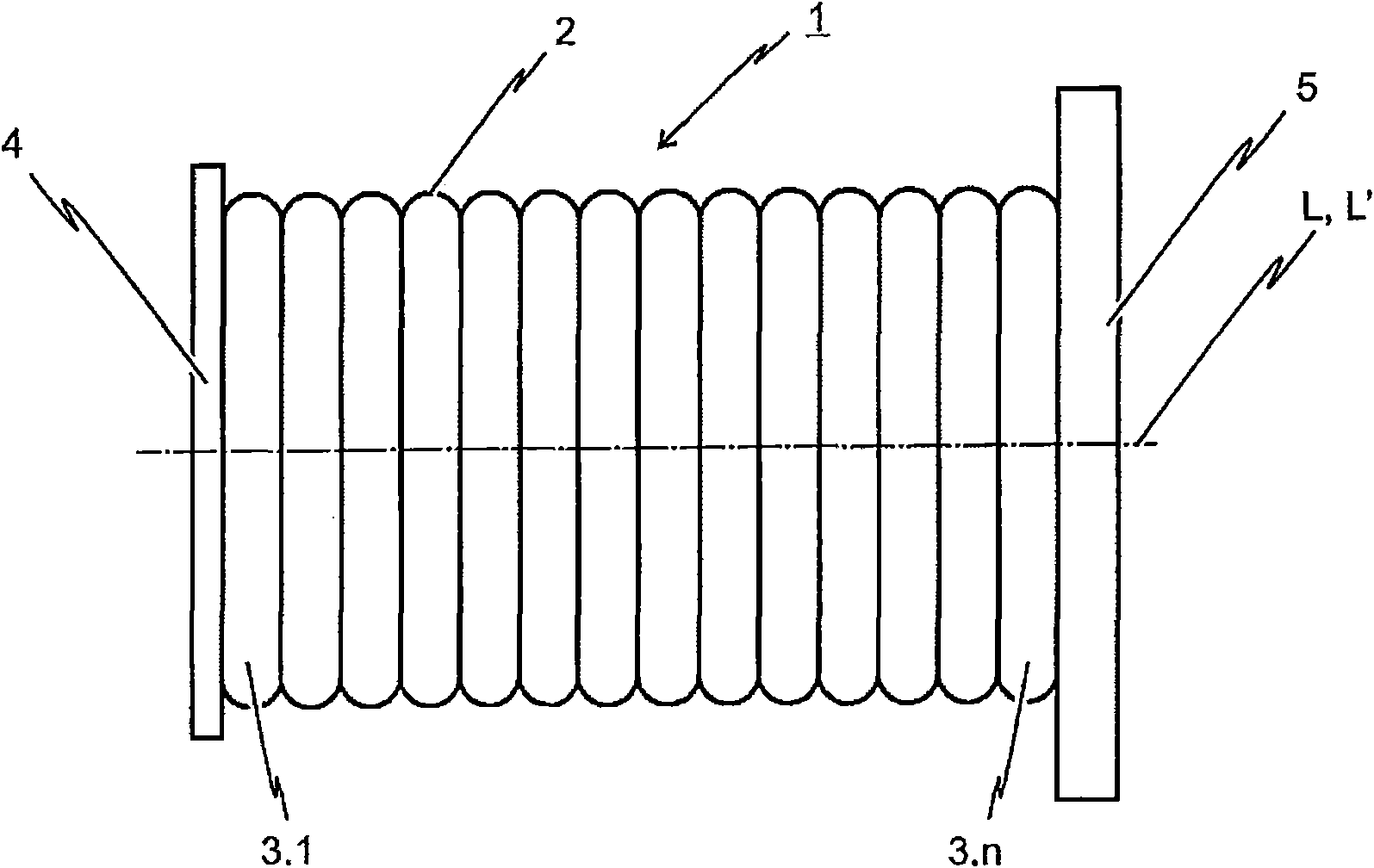

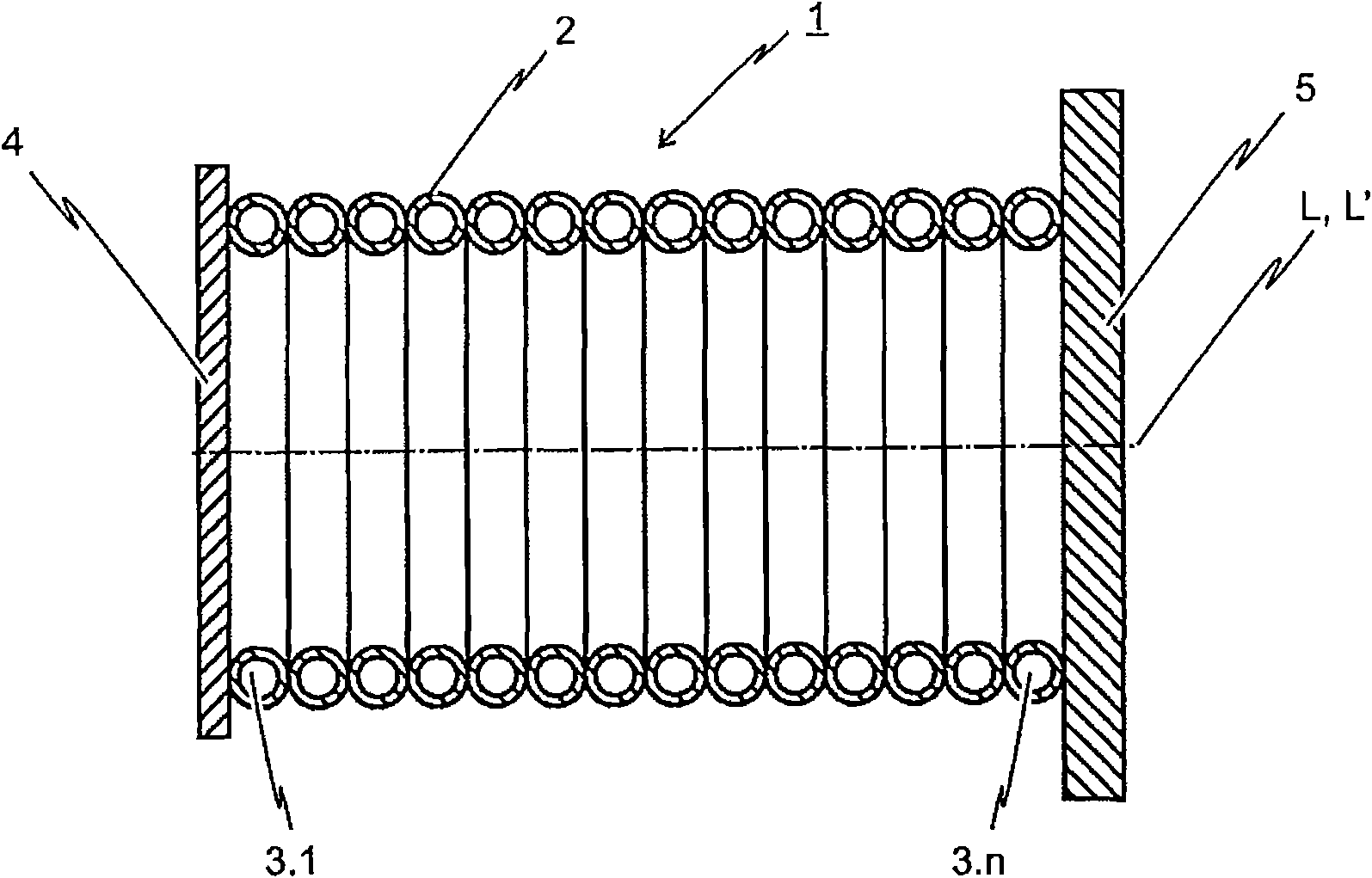

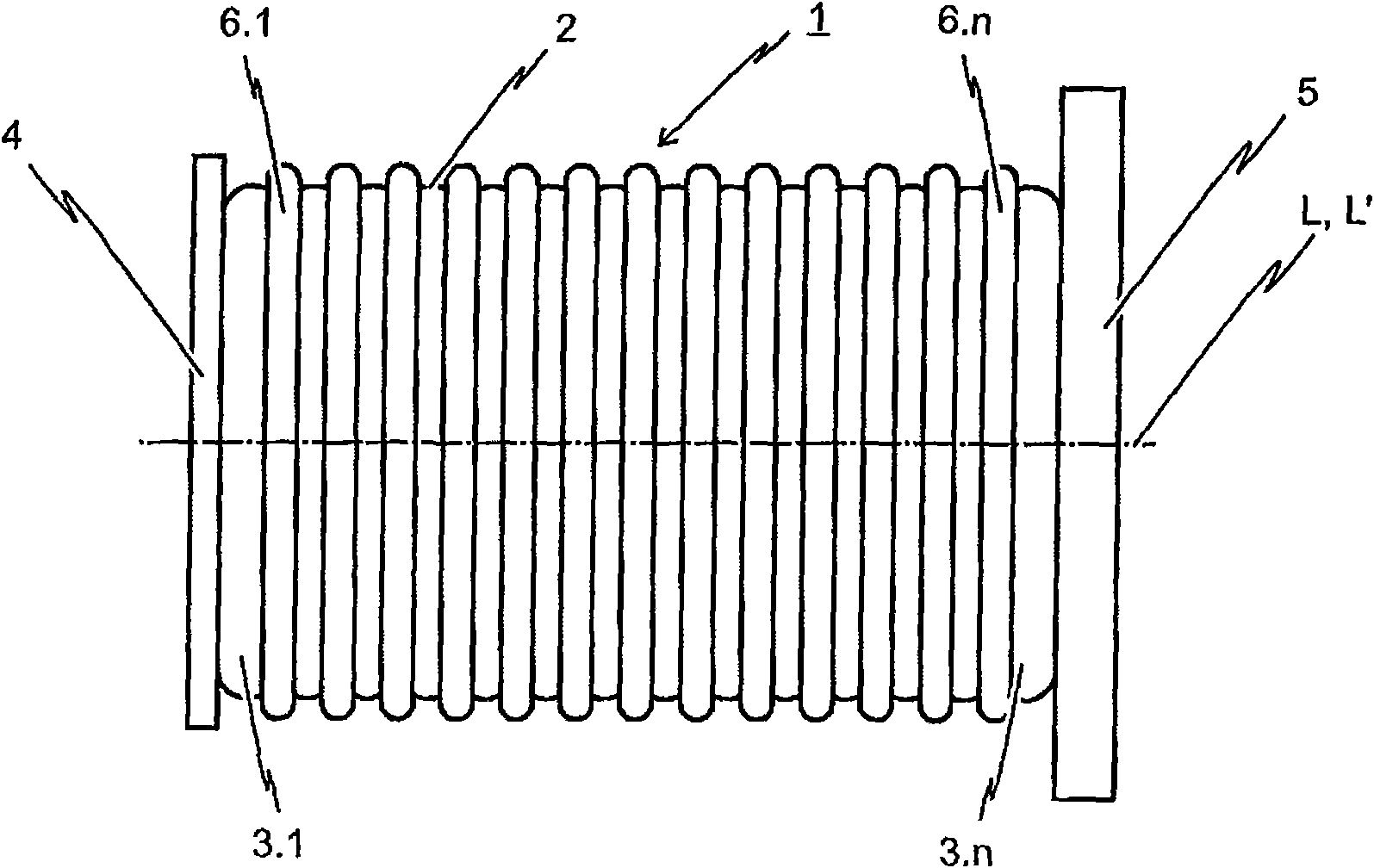

[0038] figure 1 A side view of a first embodiment of the invented energy dissipating element 1 is depicted. The energy dissipation element 1 is arranged between the force transmission element 4 and the base plate 5 such that the compressive force introduced into the force transmission element 4 is transmitted to the base plate 5 through the wall 2 of the energy dissipation element 1 . As depicted, the energy dissipating element 1 is configured in the form of a hollow body extending in the longitudinal direction L. As shown in FIG. The peripheral surface of the hollow body is formed by the wall 2 of the energy dissipating element 1 .

[0039] according to figure 1 A first embodiment of the inventive energy dissipating element 1 depicted in , the wall 2 of said energy dissipating element 1 is formed by a plurality of annular deformation elements 3.1 to 3.n. These annular deformation elements 3.1 to 3.n are arranged such that the axis of rotation L' of each annular deformation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com