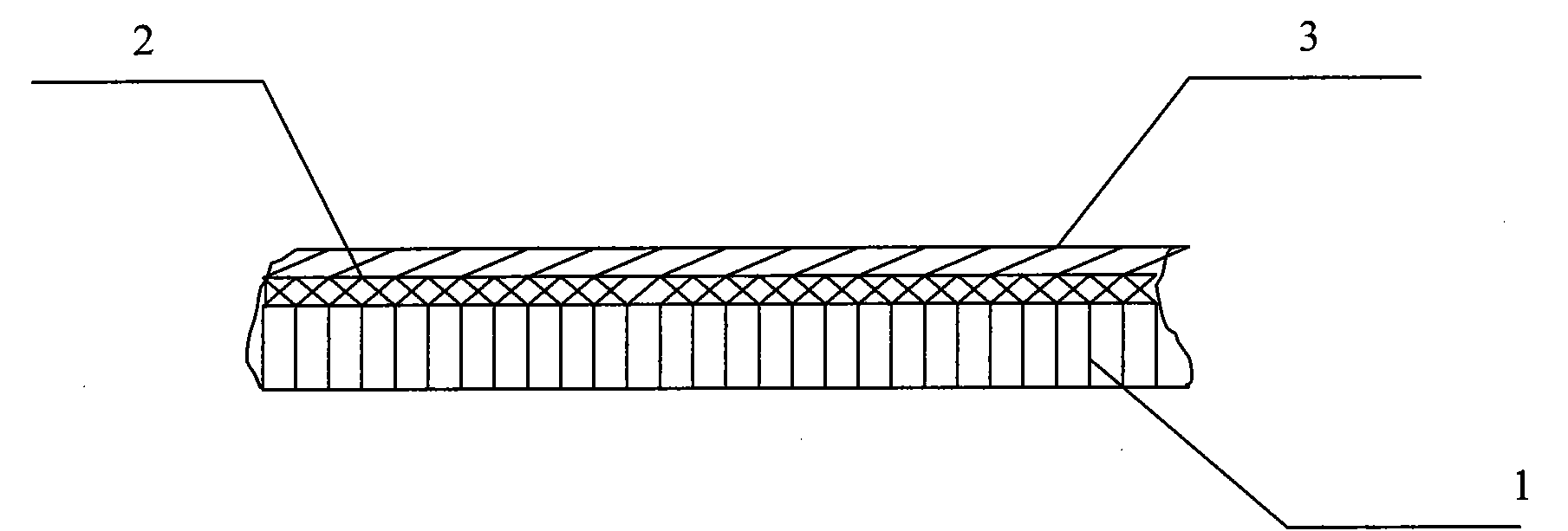

Paper-plastic composite antirust wrapping plate and manufacturing method thereof

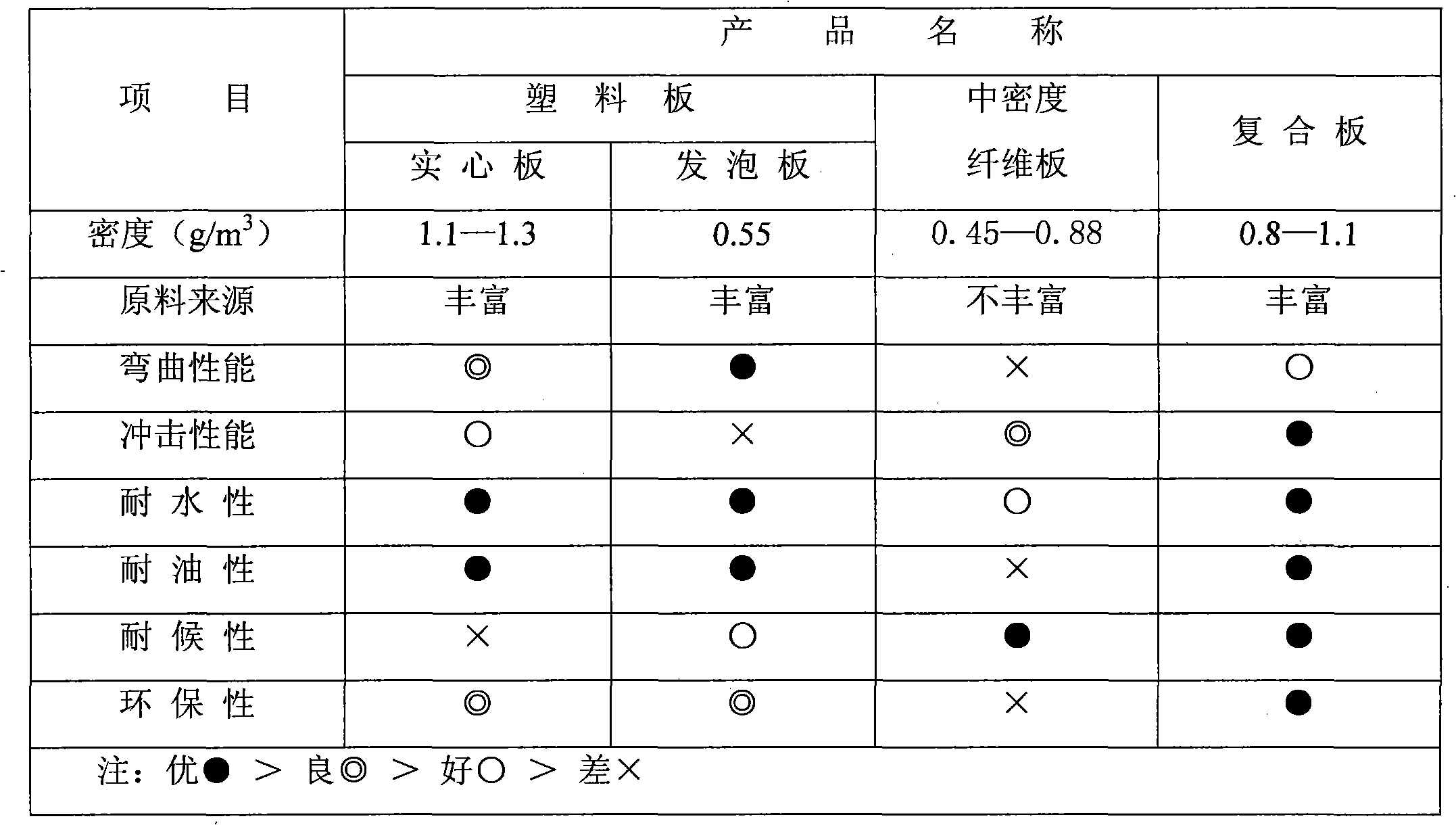

A technology of paper-plastic composite and production method, which is applied in the field of steel packaging materials, can solve the problems of poor water and oil resistance and bending performance, oil leakage, cracking, breaking, and high cost of PE plastics, and achieves enhanced moisture resistance and moisture resistance. low cost, easy to produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In the raw material, the plastic is PE, the amount is 48%; the amount of paper is 49.75%; the amount of high-efficiency anti-rust powder is 1.5%; the antistatic agent is Atmer 129V, the amount is 0.75%. The above formula is processed according to the production process, the heating temperature is 190°C, the pressure is 3Mpa, and the pressure is maintained for 5 minutes.

Embodiment 2

[0027] Among the raw materials, the plastic is PP, the amount is 35%; the amount of paper is 62.5%; the amount of high-efficiency anti-rust powder is 1%; the antistatic agent is Atmer 163, the amount is 1.5%. The above formula is produced according to the production process, the heating temperature is 120°C, the pressure is 2Mpa, and the pressure is maintained for 8 minutes.

Embodiment 3

[0029] The plastic in the raw material is M PE : M EVA =3:1, the total dosage is 25%; the dosage of paper is 72%; the dosage of high-efficiency anti-rust powder is 0.5%; the antistatic agent is M Atmer129V : M Atmer163 = 2:1, the total amount is 2.5%. The above formula is produced according to the production process, the heating temperature is 140°C, the pressure is 1.5Mpa, and the pressure is maintained for 11 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com