Rough surface compounding method

A composite method, rough surface technology, applied in bonding methods, adhesives, etc., can solve the problems of high processing cost, complex processing process, environmental pollution, etc., and achieve the effect of improving bonding fastness, simplifying process, and good environmental performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

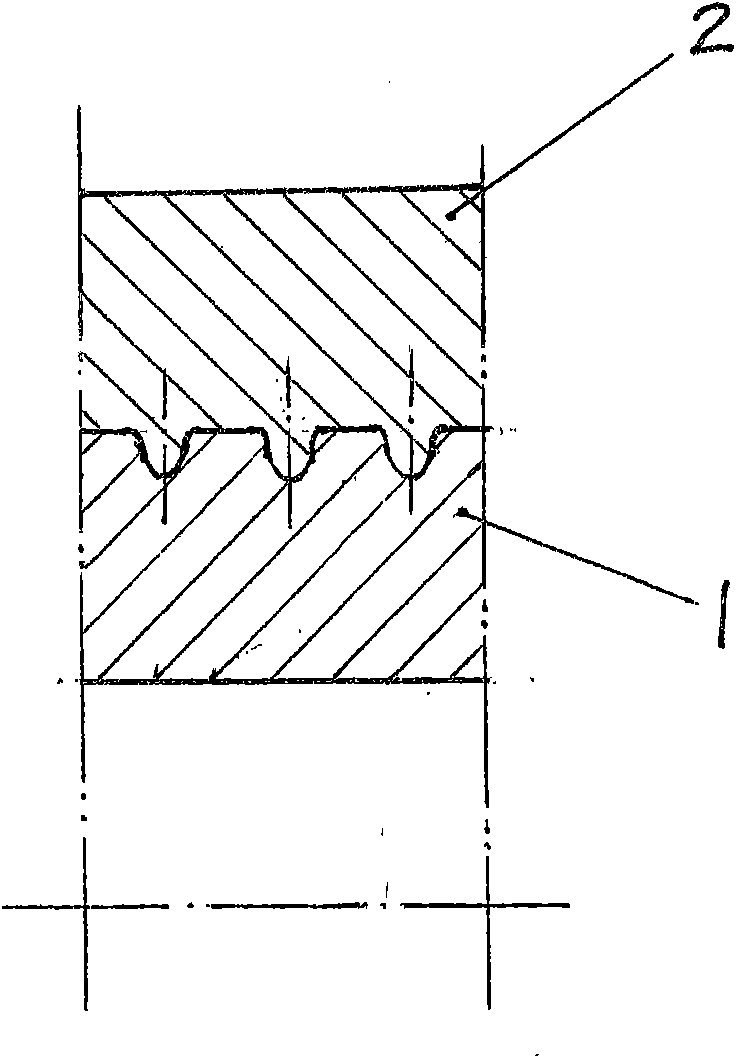

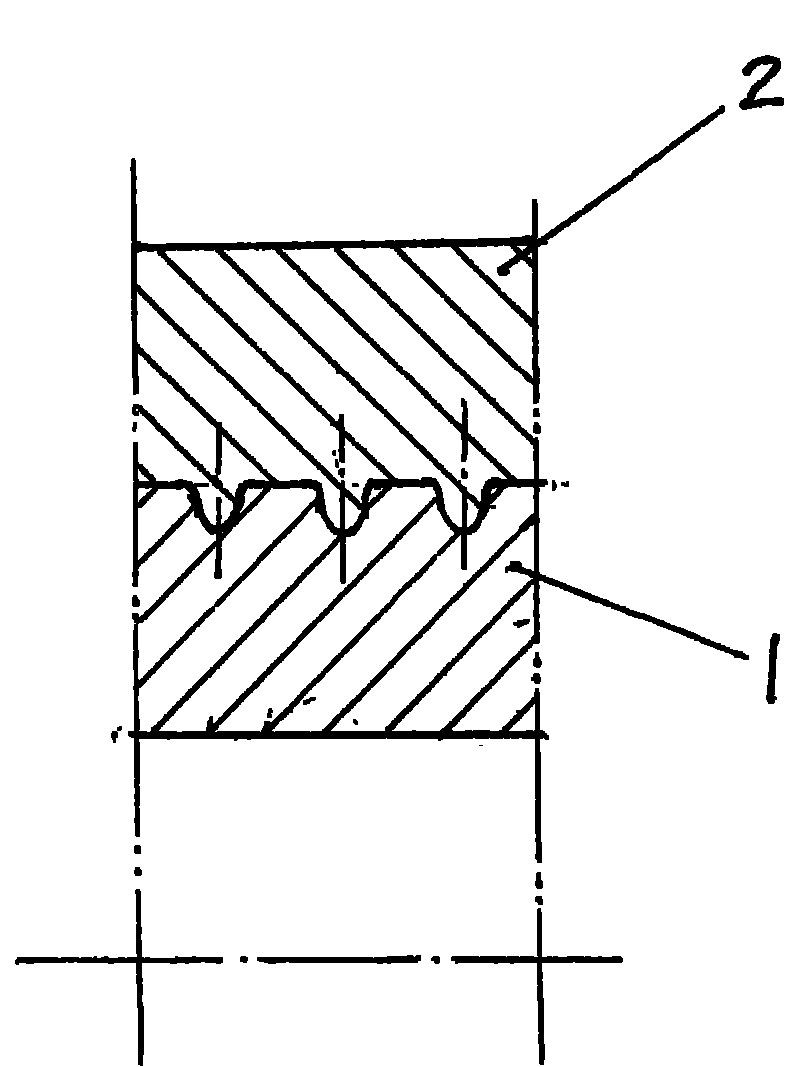

[0013] see figure 1 As shown, the inner layer pipe 1 selects a rough pipe with dense pits on the outer surface. When making the composite pipe, the adhesive is evenly distributed on the entire outer surface of the inner layer pipe 1, and then the outer layer rubber 2 is compounded on the outer layer and pressure is applied so that the outer layer rubber 2 fills the recesses on the outer surface of the inner layer pipe 1. In the pit, and prevent the generation of air bubbles. The outer rubber 2 is firmly bonded and engaged with the inner tube 1 after vulcanization. The bonding fastness is improved, thereby effectively preventing the two layers of materials from being separated or slipping each other on the bonding interface.

[0014] As mentioned above, the present invention solves the problems of improving the bonding fastness, simplifying the manufacturing process, not using toxic and harmful chemicals, and protecting the environment when more than two layers of composite m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com