Combined type integral casting building template

A building formwork and combined technology, which is applied in the direction of construction, building structure, formwork/formwork/work frame, etc., can solve the problems of high cost, not worth promoting, and the inability to produce formwork width and thickness, etc., to reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

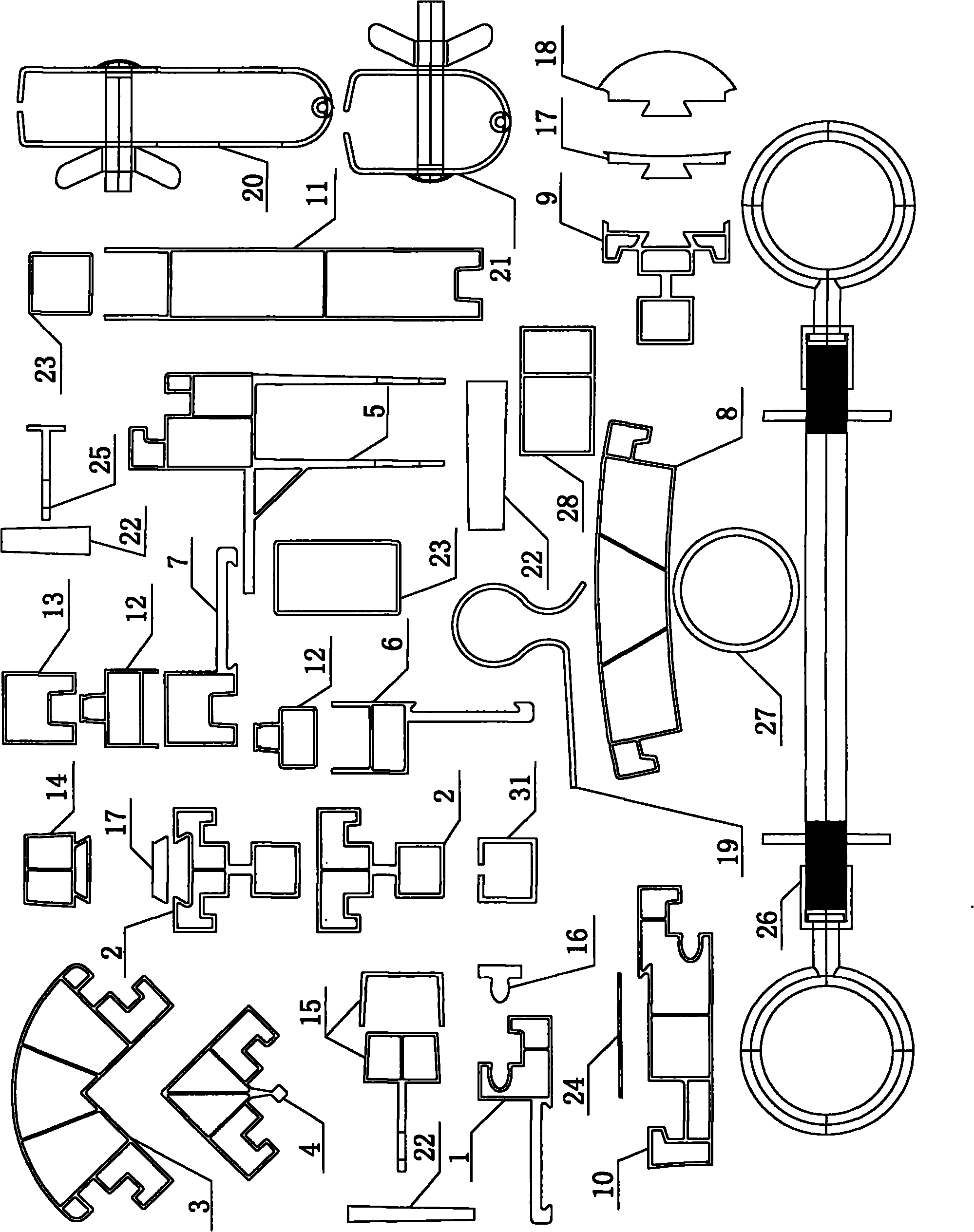

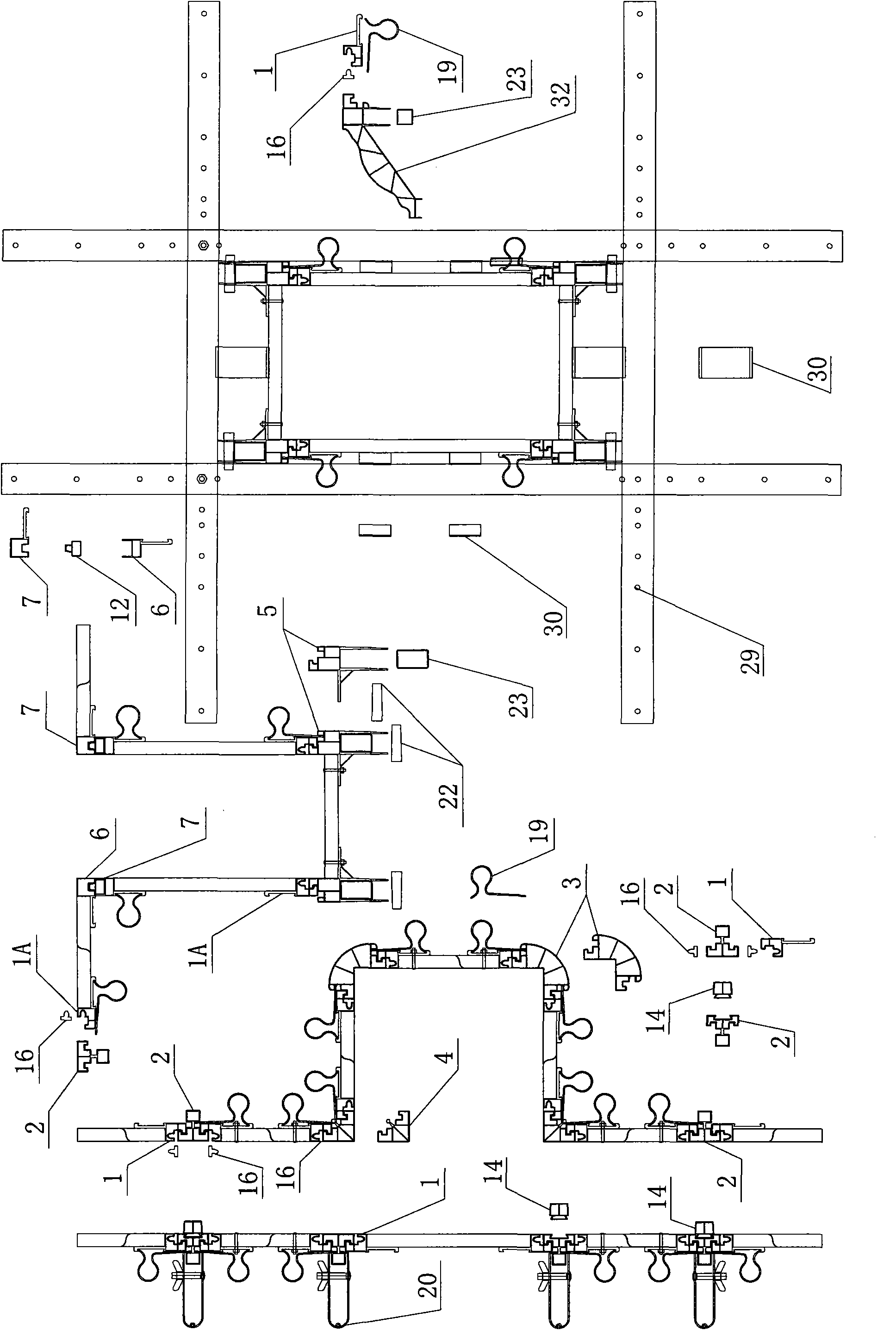

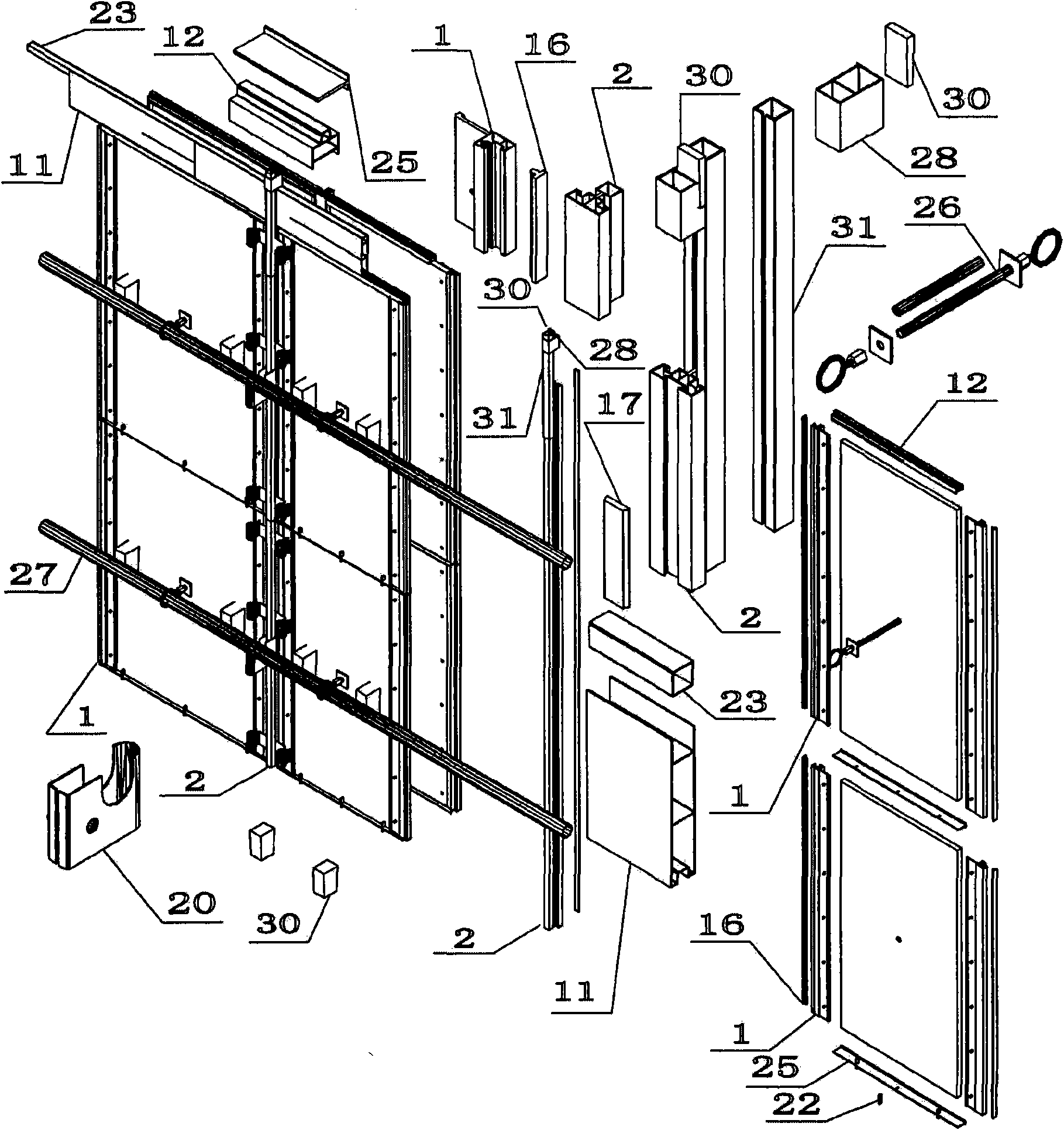

[0031] see Figure 1 to Figure 3As shown, the wall building vertical form 1 is a hollow profile with grooves on both sides, and the middle is equipped with solid forms of different lengths and widths, and the wall building vertical form 1 of different lengths and widths is combined with screws. The floor can also be used as a column formwork, the difference is that it is used for the wall formwork, with a round hole drilled in the middle, while there is no round hole for the floor formwork and the column formwork. Wall and floor clips 2, outer corner moulds 3, and inner corner moulds 4 are hollow profiles with convex grooves, and the length is the height of the wall or the width of the floor, of which the wall and floor clip 2 can be used as both Wall buckle form, can also be used as floor buckle form. The combination of convex and groove buckles is formed by a uniform length of wall and floor buckle mould 2, outer wall corner mould 3, inner wall corner mould 4, and several w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com