Wall-hanging-type heat collector adopting half-edge compound parabolic concentrating devices

A compound paraboloid and concentrating device technology, which is applied in the field of solar energy concentrating and heat collecting, can solve the problems of high requirements for fixing devices, low utilization rate of solar energy, low heat collecting temperature, etc. high temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

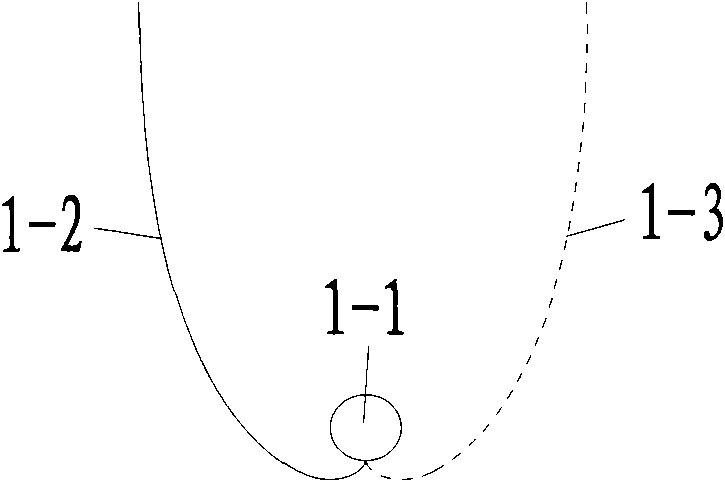

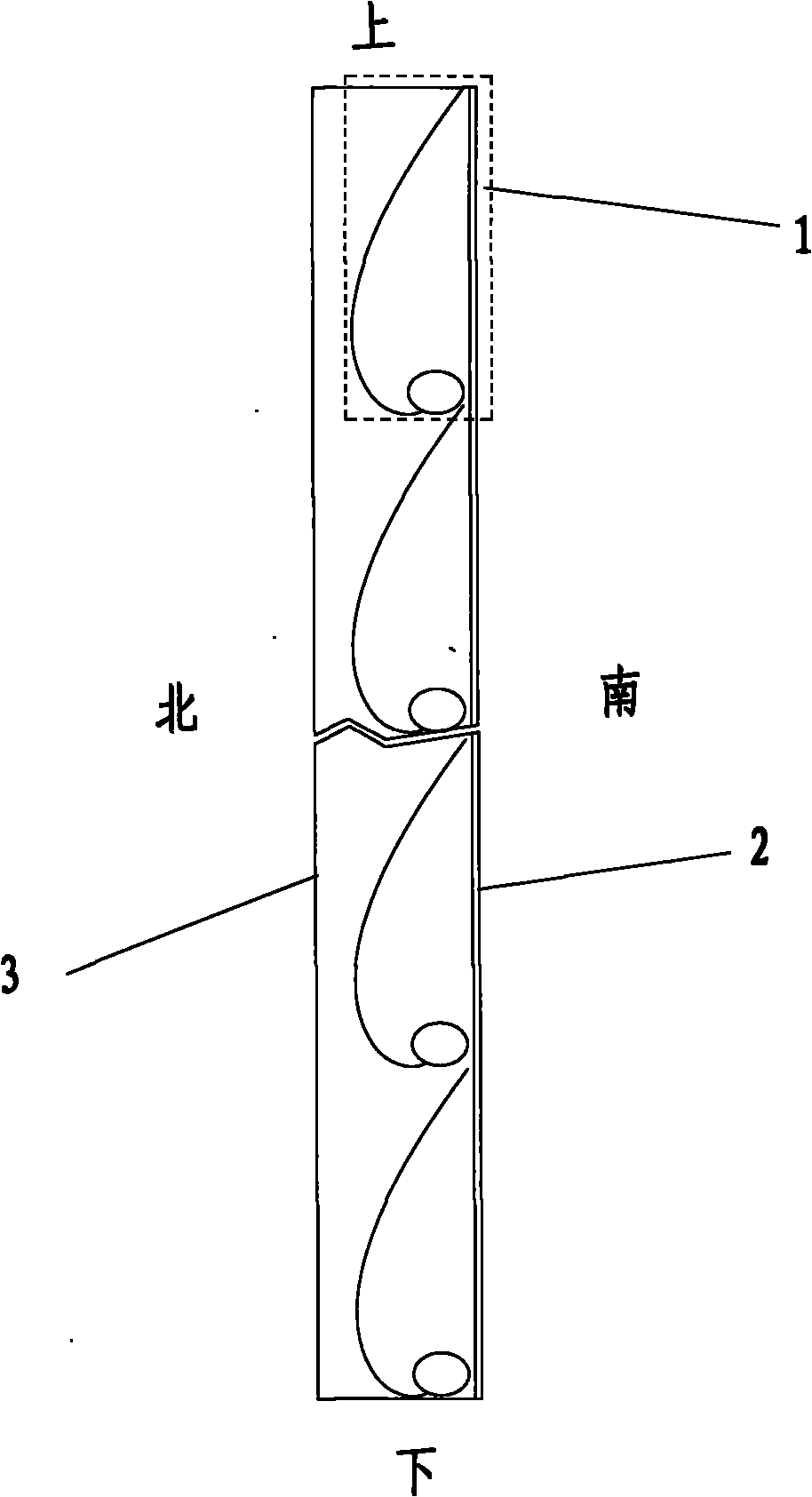

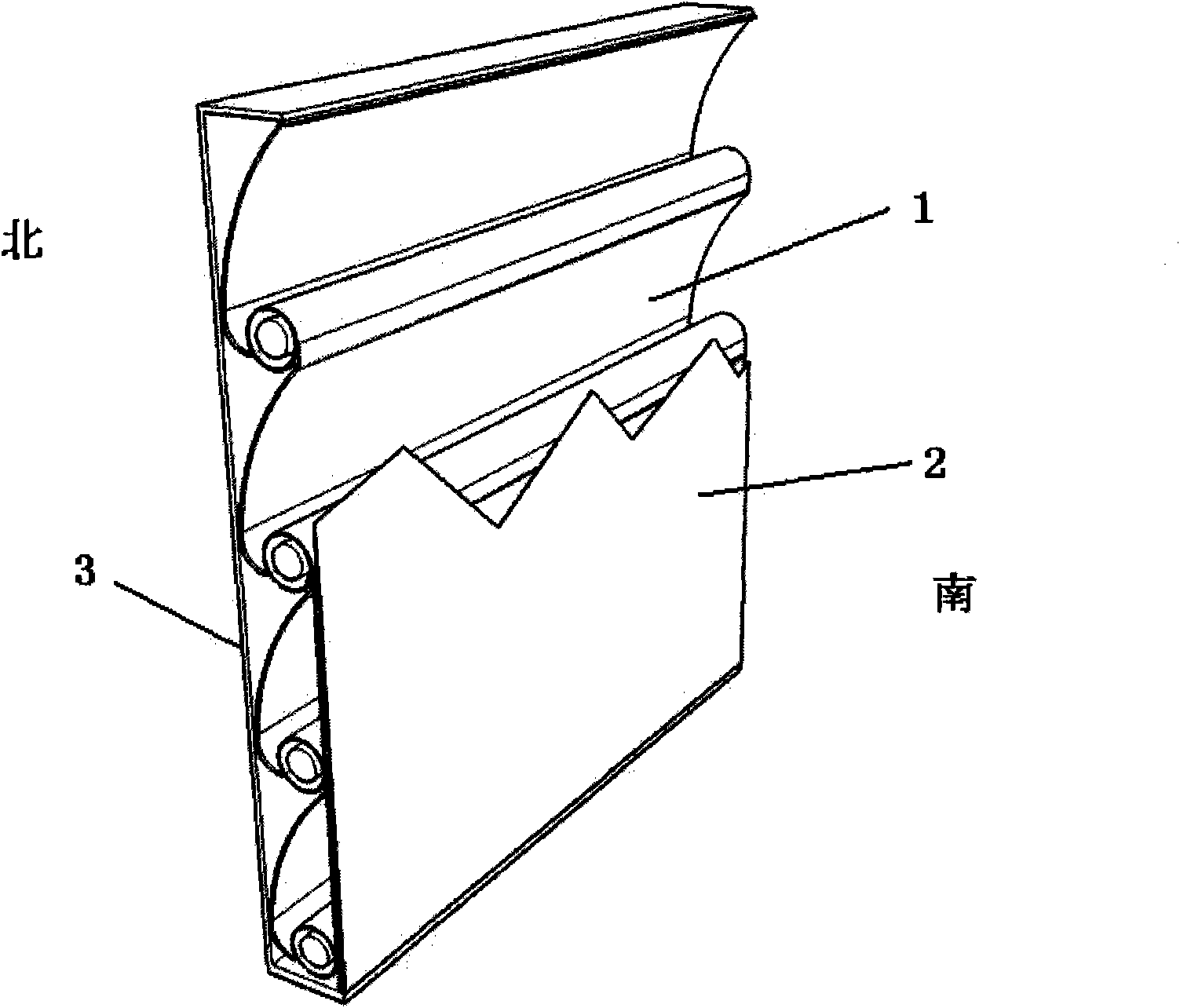

[0033] The device contains four half-sided compound paraboloid concentrating devices 1, and the receiving half angle of the compound paraboloid is 30°. Half compound parabolic reflector 1-2 adopts aluminum plate. The glass vacuum heat collecting tube 1-1 is a straight-through vacuum heat collecting tube. The glass plate 2 is made of high borosilicate glass 3.3 with good light transmission performance. External frame 3 adopts corrosion-resistant, light organic plastics. The plane formed by multiple half-side compound parabolic concentrating devices 1 and the glass plate 2 are placed vertically.

Embodiment 2

[0035] The device contains four half-sided compound paraboloid concentrating devices 1, and the receiving half angle of the compound paraboloid is 30°. Half compound parabolic reflector 1-2 adopts aluminum plate. The glass vacuum heat collecting tube 1-1 is a straight-through vacuum heat collecting tube. The glass plate 2 is made of high borosilicate glass 3.3 with good light transmission performance. External frame 3 adopts corrosion-resistant, light organic plastics. The plane and the glass plate 2 formed by multiple half-side compound paraboloid light concentrating devices 1 are placed on the basis of the vertical direction and rotated 15° to the north.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com