Organic electroluminescent display with multicolor regions and method for manufacturing same

A luminescent and display technology, applied in the area multi-color organic electroluminescent display and its manufacturing field, can solve the problems affecting the visual effect of the picture, discontinuous display patterns, etc., and achieve the effect of continuous display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

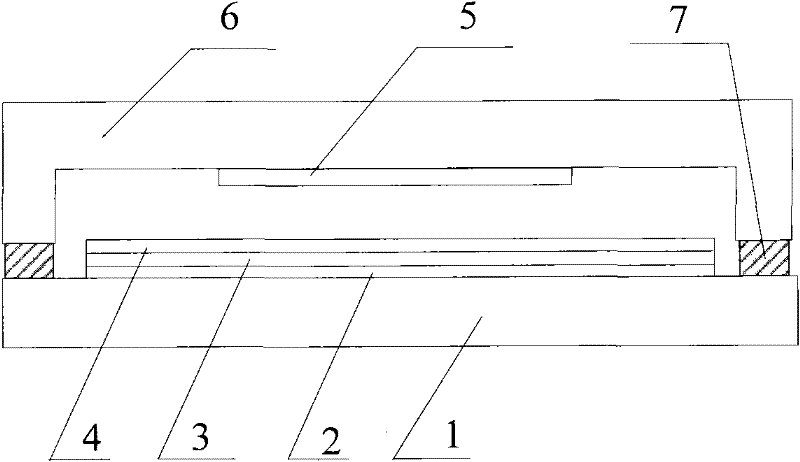

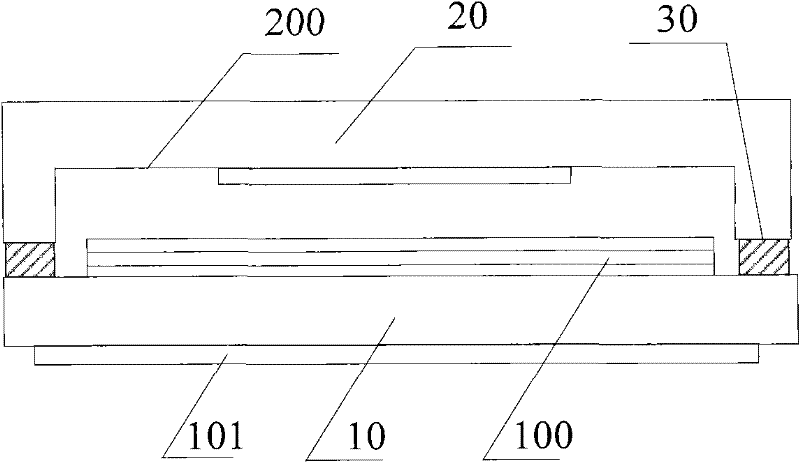

[0039] This embodiment provides an area multicolor OLED, such as figure 2 As shown, the area multi-color OLED includes a substrate 10 , a back cover 20 and an encapsulant 30 .

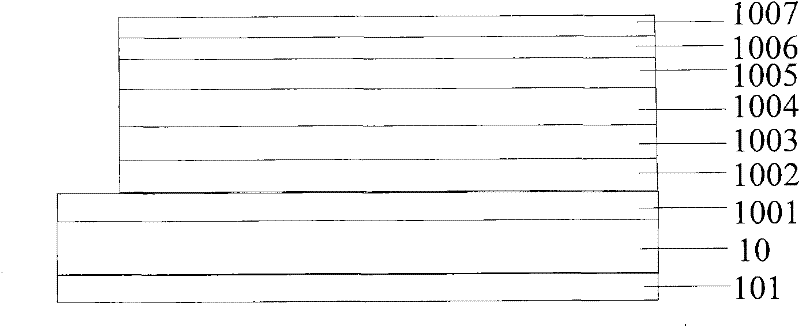

[0040] The upper surface of the substrate 10 has a matrix of pixel display areas 100 of the same color, and the lower surface is formed with filters 101 of more than two color areas. Such as image 3 As shown, the pixel display area matrix 100 includes, from bottom to top, an anode 1001, a hole injection layer 1002, a hole transport layer 1003, a light emitting layer 1004 of the same color, an electron transport layer 1005, an electron injection layer 1006 and a cathode 1007. In the present invention, the organic materials of the light-emitting layer 1004 are the same, so there is no need to perform multiple alignments during the manufacturing process, and a single-color OLED can be produced first, which simplifies the process flow, improves production efficiency, and does not require complicated des...

Embodiment 2

[0053] This embodiment provides a method for manufacturing an area multicolor OLED, such as Figure 7 shown, including:

[0054] S10, providing a substrate and a back cover; the upper surface of the substrate has a matrix of pixel display areas of the same color, and the back cover has a light emitting area corresponding to the matrix of pixel display areas.

[0055] The method for manufacturing an area multi-color OLED in this embodiment is different from depositing different organic functional layers on pixel unit positions corresponding to different colors in the prior art, but depositing the same organic functional layer on all pixel units, that is, all pixel units It emits light of the same color.

[0056] The formation process of the pixel display area matrix of the same color on the upper surface of the substrate may specifically include: sequentially depositing and forming an anode, a hole injection layer, a hole transport layer, a light emitting layer of the same col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com