Electrode connection structure of semi-conductor electric heating piece

A connection structure and semiconductor technology, applied in the direction of ohmic resistance electrodes, ohmic resistance heating parts, etc., can solve the problems of reduced contact area, large contact resistance between electrodes and the body, and affecting the performance of semiconductors, so as to expand the conductivity Effect of contact area and reduction of contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

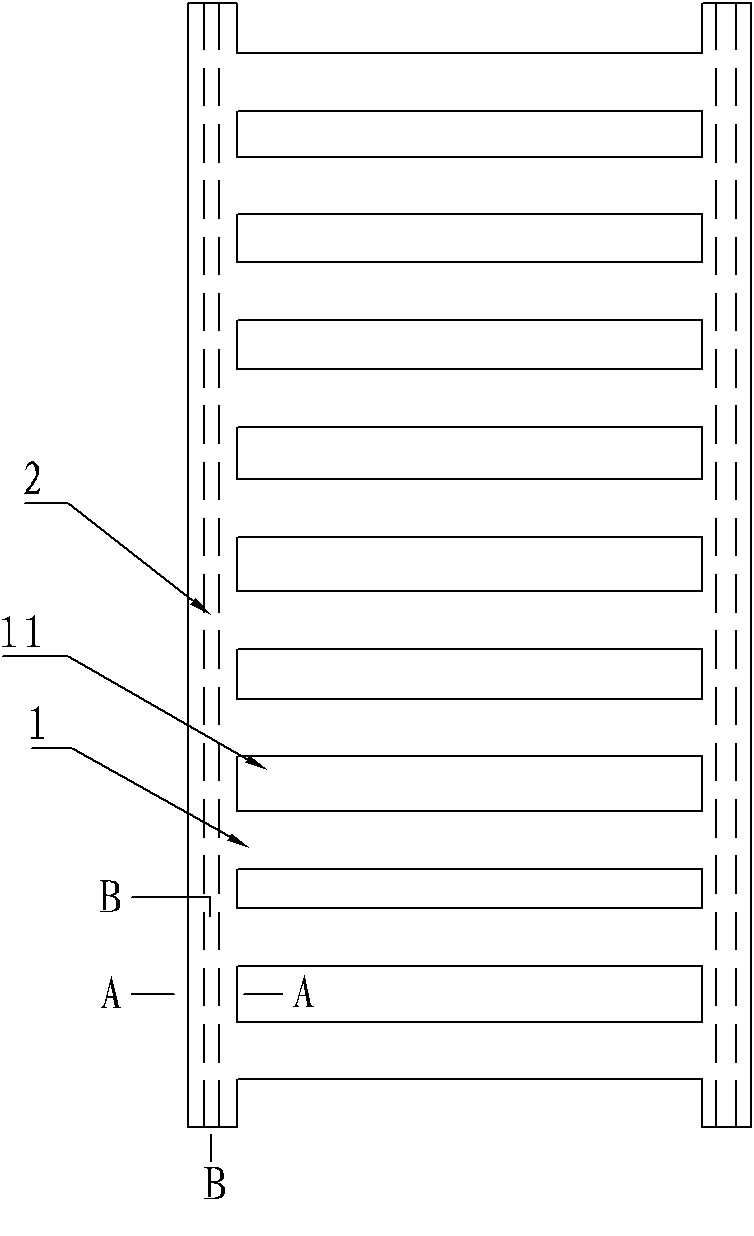

[0016] The present invention takes the self-limiting temperature electric heater as an example, as figure 1 As shown, the self-limiting temperature electric heater in the present invention includes a body 1 and two electrodes 2 embedded in the body 1. The body 1 is in the shape of a flat rectangular sheet, and a plurality of strips of equal length are arranged in parallel on the body 1. The two electrodes 2 are respectively arranged in the body 1 at both ends of the strip-shaped through-holes 11 .

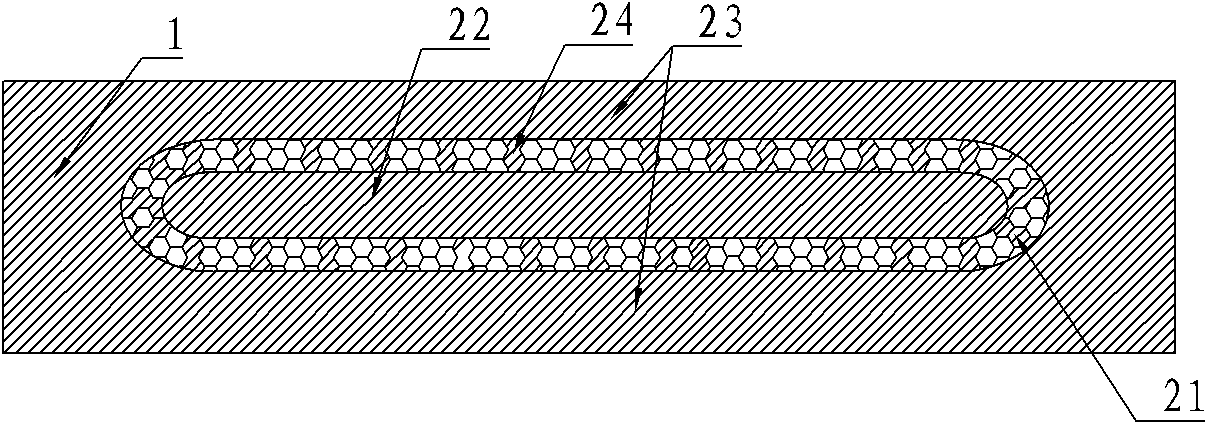

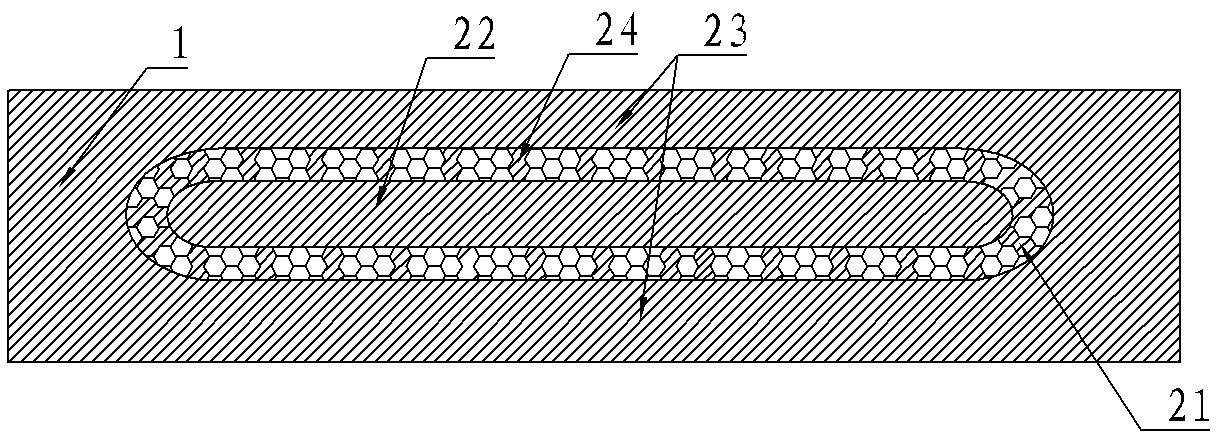

[0017] like figure 2 shown, for figure 2 In the cross-sectional view of the electrode in A-A, the electrode 2 is a strip structure with a hollow inner side and a mesh 21. The body part 22 inside the electrode is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com