Socket

A socket and socket panel technology, applied in the direction of contact parts, fixed/insulated contact members, electrical components, etc., can solve the problems of increasing the contact area, and the deformation of the copper sheet cannot be recovered, so as to increase the conductive contact area and prevent extrusion deformation. , the effect of reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

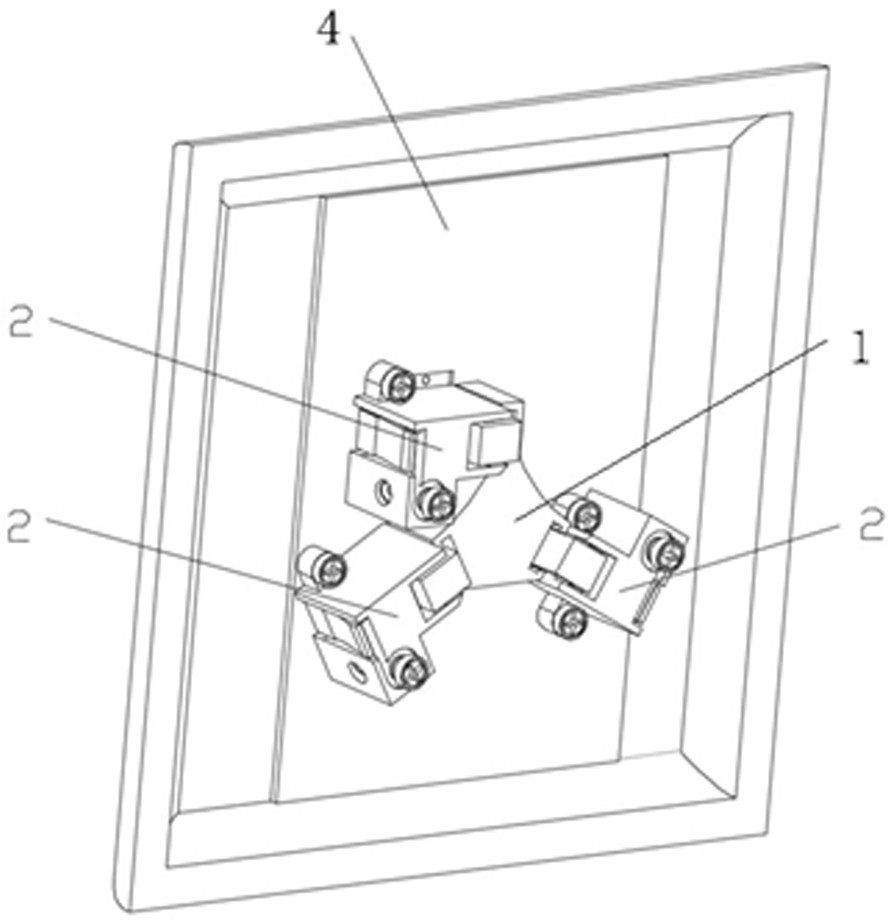

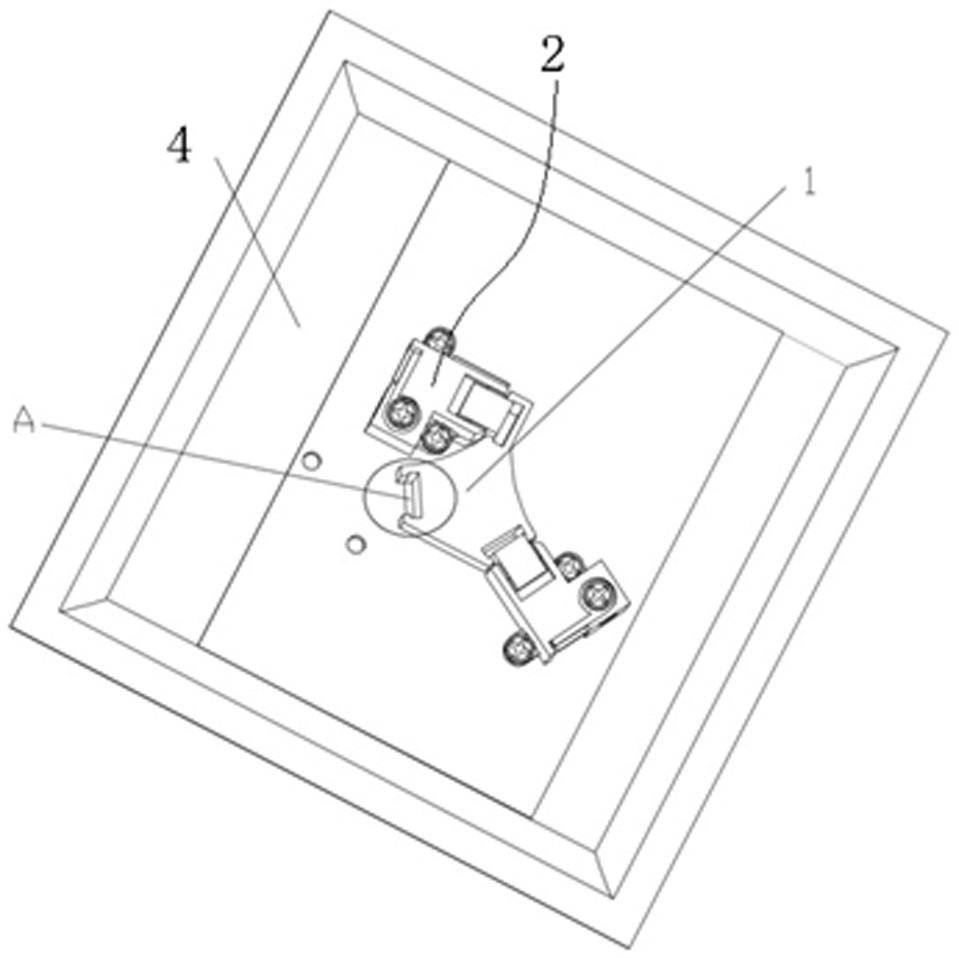

[0038] Example 1, see Figure 1-Figure 6 ,as well as Figure 12-13 , a socket provided in this embodiment is provided with a socket panel 4 , and the socket panel 4 is provided with a latch 31 and a fixing frame 1 .

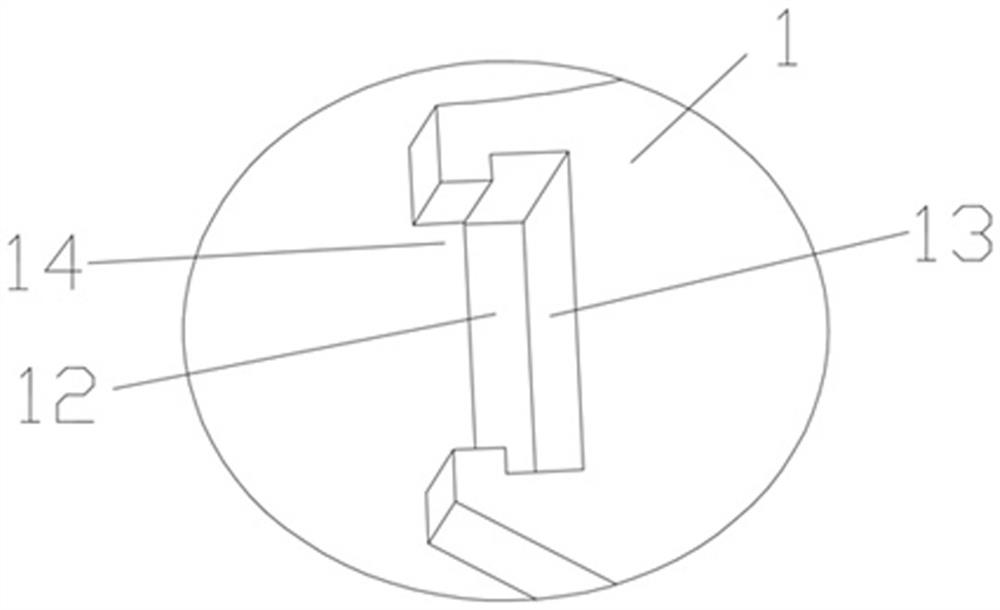

[0039] The fixed frame 1 of the latch 31 is provided with a latch groove 12 adapted to fit the plug 3 latch 31, and one side of the latch groove 12 is provided with a notch 14, which facilitates the movement of the connecting sheet 21 of the electrical connection system 2 .

[0040] The fixing frame 1 of the bolt 31 is arranged inside the socket panel 4 , and the bolt groove 12 extends toward the outside of the socket panel 4 and intersects with the outside of the socket panel 4 to form a bolt hole. The pin holes can be provided with two pin holes or three pin holes, which are adapted to two-pin plugs 3 or three-pin plugs and four-pin plugs 3 respectively.

[0041] The inner side of the socket is provided with an electrical connection system 2, the electrical ...

Embodiment 2

[0049] Example 2, see Figure 7-Figure 13 , a socket provided in this embodiment, embodiment 2 is basically the same as embodiment 1, the difference is that the bolt 31 fixing frame 1 and the mounting base 23 are connected into one structure.

[0050] The latch 31 fixing frame 1 is provided with a latch groove 12 adapted to match the latch 31 of the plug 3 . The plug groove 12 and the mounting seat 23 are connected as a whole to form a rectangular cavity. One side of the rectangular cavity is a mounting groove for the connecting plate, and the conductive contact plane 211 of the connecting plate 21 is embedded in the slotting groove. The distance between the conductive contact plane 211 of the electric piece 21 and the side wall of the slot is smaller than the thickness or diameter of the pin 31 of the plug 3 .

[0051] The mounting base 23 is provided with an external power access hole 28 , and the external power access hole 28 communicates with the external power connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com