Impact-modified polypropylene

A polypropylene, propylene technology, applied in the field of polymer compositions with high impact strength, can solve problems affecting low temperature applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

test approach I

[0143] Based on the standard test method ISO 16014-2: 2003 and ISO 6014-4: 2003, the weight average molecular weight (Mw) and the number average molecular weight (Mn) are measured by molecular exclusion chromatography (SEC) and the molecular weight distribution (MWD= Mw / Mn).

[0144] Under 140 degrees centigrade, adopt online viscometer in Waters Alliance GPCV2000SEC instrument (eluent is 1,2,4-trichlorobenzene ( TCB)) to measure molecular weight average and molecular weight distribution. A combination of 2 mixture beds and a TSK-Gel column (from TosoHaas), the system was calibrated with NMWD polystyrene standards (from Polymer laboratories).

[0145] 2. Melt flow rate (MFR)

[0146] At 230°C for polypropylene and at 190°C for polyethylene, the load is 2.16kg (MFR 2 ), to measure the melt flow rate. The melt flow rate refers to the amount (in grams) of polymer extruded within 10 minutes by a test device conforming to the ISO 1133 standard at a temperature of 230°C or 190...

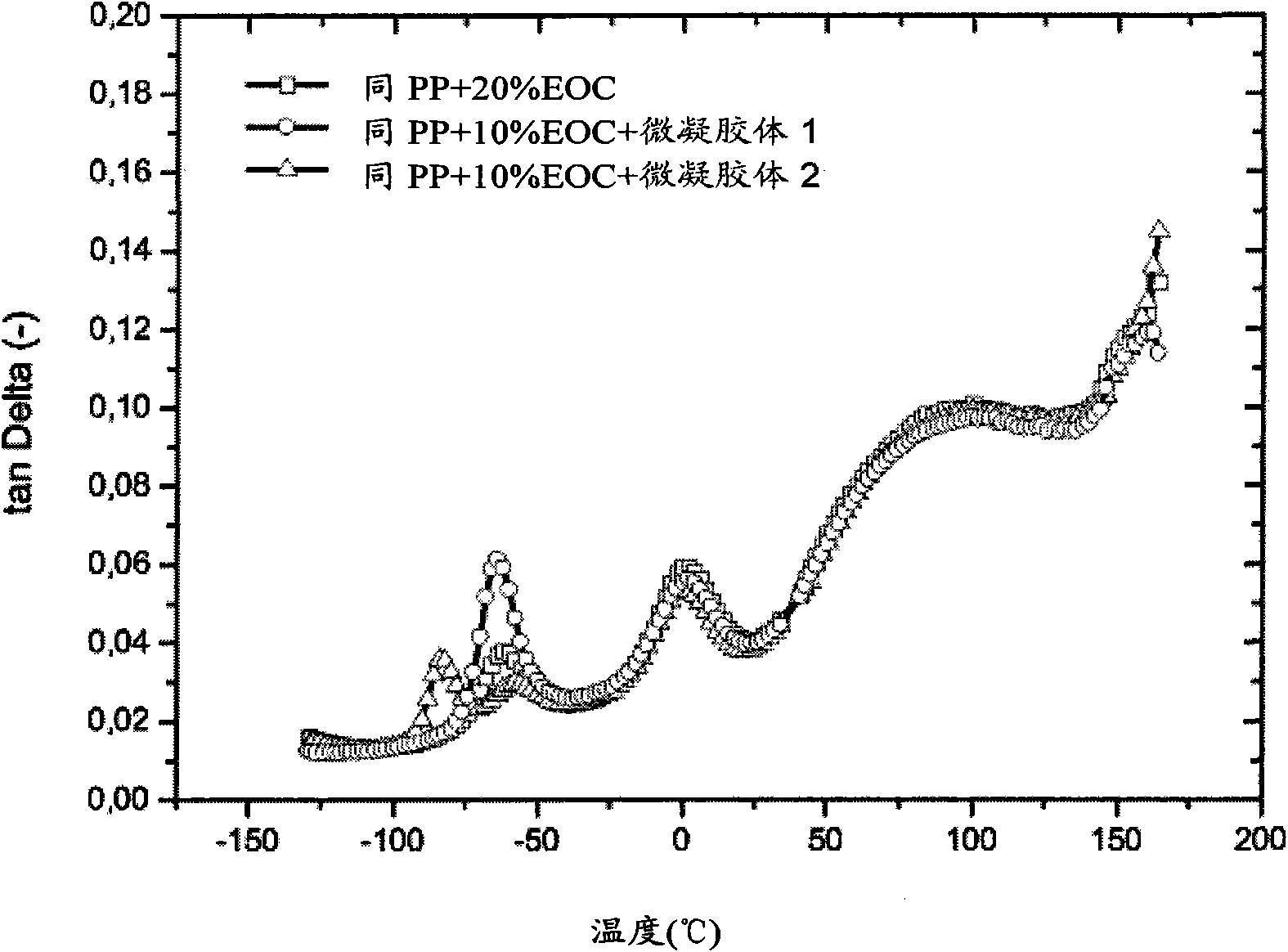

Embodiment 1(Ex1) and comparative Embodiment 1-3

[0168] Embodiment 1 (Ex1) and comparative examples 1-3 (CE1-3)

[0169] In all these examples the propylene homopolymer (MFR 2 (230° C.)=10 g / 10 min, Mw=330,000 g / mol and MWD=5,2) as matrix polymer.

[0170] In CE1, only a single non-crosslinked elastomeric phase consisting of ethylene / 1-octene copolymer (EOC) is dispersed in the matrix polymer. EOC has 42% by weight of C 8 unit, with a density of 0.863 g / cm 3 , MFR 2 (190°C) = 0,5 g / 10 min.

[0171] In CE2, only a single crosslinked elastomeric phase consisting of crosslinked polybutadiene rubber (named microgel 2, with an average particle size of 400 nm) was dispersed in the matrix polymer.

[0172] In CE3, the elastomeric EOC phase used in CE1 and the crosslinked polyisoprene rubber (designated Microgel 1, with an average particle size of 400 nm) were dispersed in the matrix polymer.

[0173] In Ex1, the elastomeric EOC phase used in CE1 and the cross-linked polybutadiene rubber (named microgel 2) were dispersed in th...

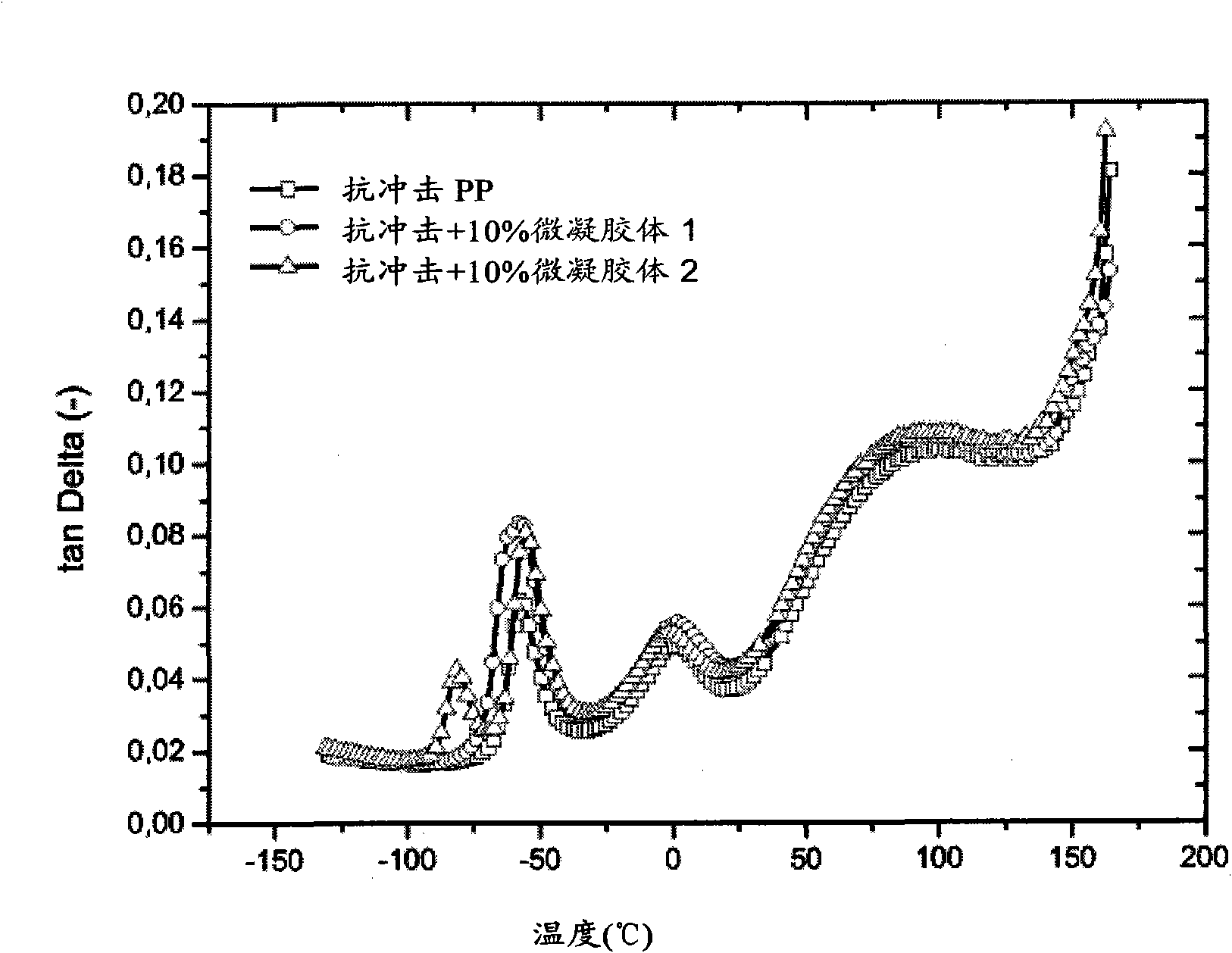

Embodiment 2 and comparative Embodiment 4-6

[0197] In all examples, high impact polypropylene was used. Impact PP is a reactor blend of propylene homopolymer and ethylene / propylene rubber dispersed in it. Dispersed EPR represents the first elastomeric phase. The impact polypropylene is produced in a multi-stage polymerization process consisting of 1 loop reactor and 1 gas phase reactor using conventional Ziegler Natta catalyst systems known in the art. In the loop reactor, a propylene homopolymer having an MFR of 25 g / 10 min was produced. The polymer is transferred to a gas phase reactor for the production of EPR. The final composition had an MFR of 7,5 g / 10 min, an XS value of 25% by weight and an intrinsic viscosity of the xylene soluble fraction of 2,8 dl / g. The ethylene content of the xylene soluble fraction was 43.0% by weight.

[0198] In CE4, there is no additional elastomeric phase dispersed in the matrix.

[0199] In CE5, a non-crosslinked elastomeric phase consisting of ethylene / 1-octene copolymer (EOC) i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com