Unit for producing medium diameter straight seam double-sided submerged arc welded steel pipe and steel pipe forming method

A double-sided submerged arc welding technology for steel pipes, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of inability to adjust, easy to form a peach-shaped tip, fixed deformation of the pipe body, etc., and achieve shape adjustment accuracy High, short time, adjustable deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

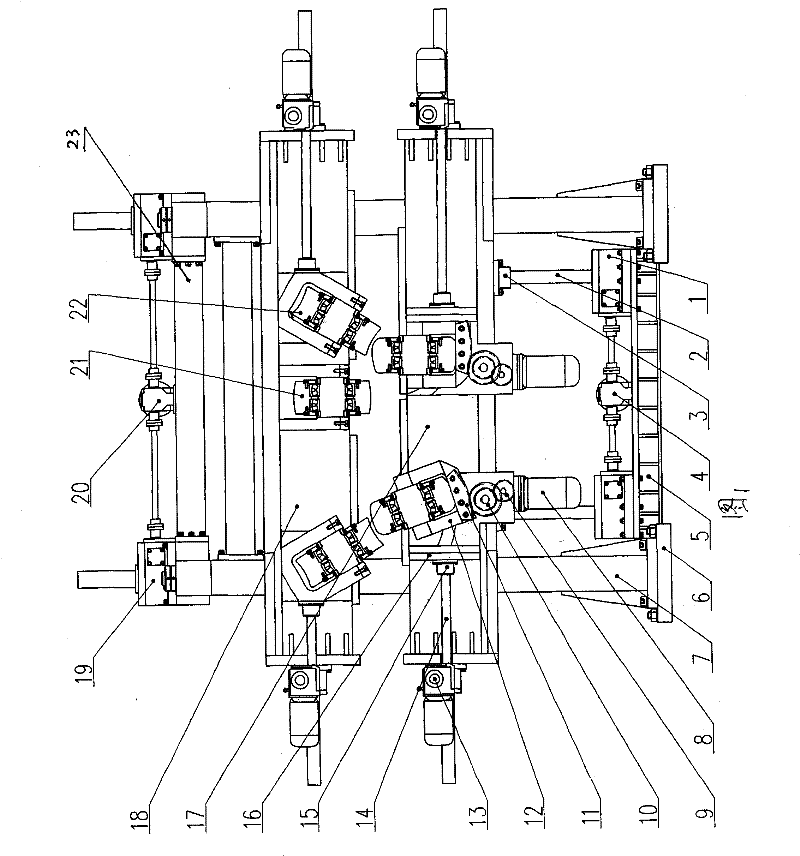

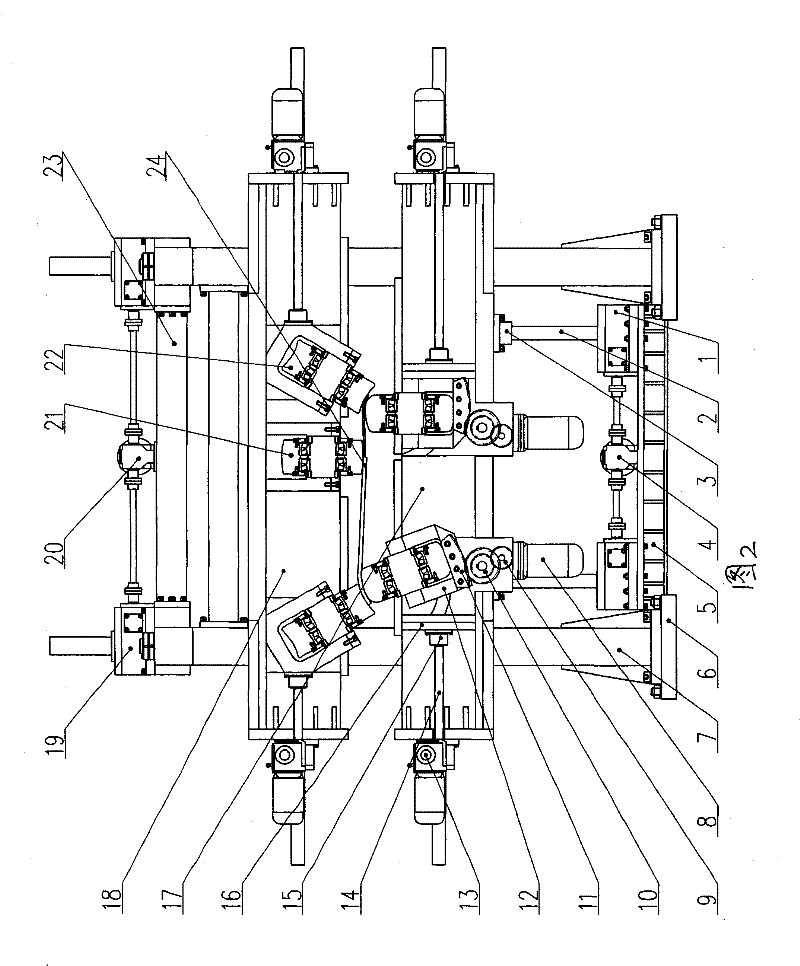

[0009] refer to figure 1 , it includes a lower beam 5, the two ends of the lower beam 5 are respectively fixed on the foundation bases 6 on both sides, two racks 7 are respectively fixed on the base bases on both sides, and a worm gear reducer is installed at each end of the lower beam 5 1. The two worm gear boxes are respectively connected to the worm gear box 4 installed in the middle of the lower beam through the connecting rods. The lower box 17 and the upper box 18 are installed on two racks and can slide up and down. There are two propulsion connection assemblies 3 fixed under the lower box, and the two propulsion connection assemblies have their own connecting screw 2 to connect with the worm wheel of the corresponding worm gear box 1 below, and the lower roller seat 12 is installed on the lower box And connected with the connecting plate 16, the lower roller base 12 is equipped with a swing connecting gear 11, a large gear 10 and a pinion 9 that are meshed in sequence,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com