Treatment method of carbon dioxide

A carbon dioxide, chemical treatment technology, applied in the direction of neutralizing water/sewage treatment, etc., can solve the problems of increasing electrical conductivity, unable to reduce the temporary hardness of wastewater, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

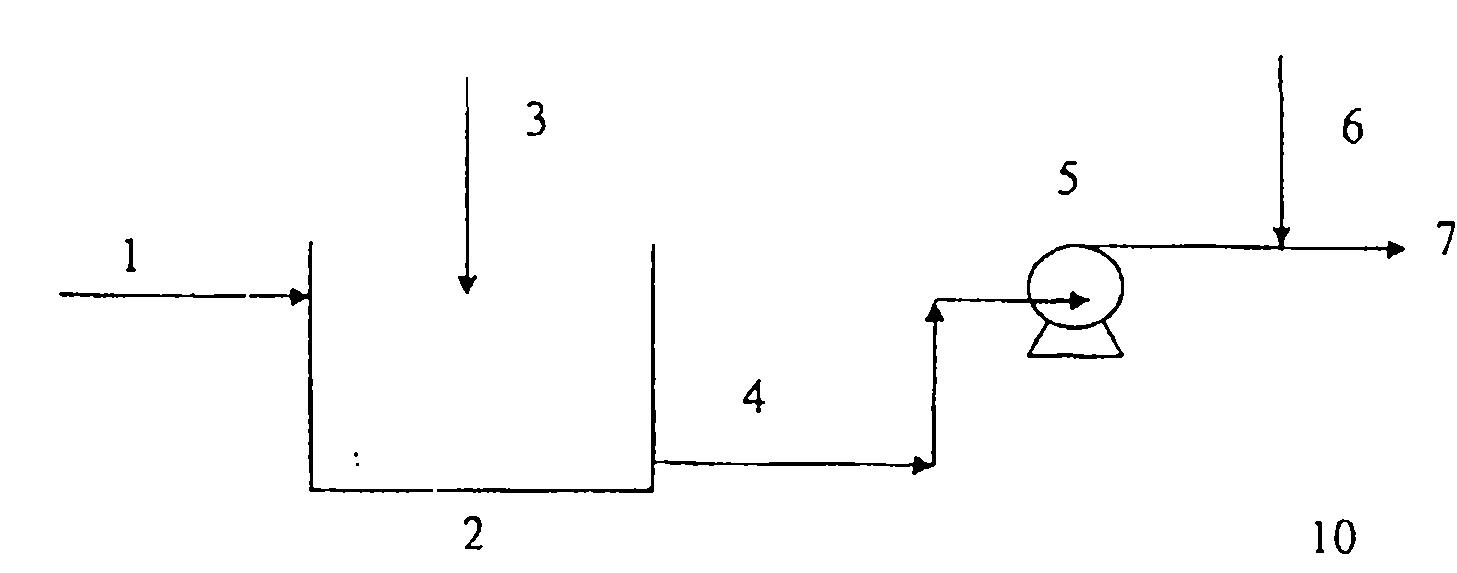

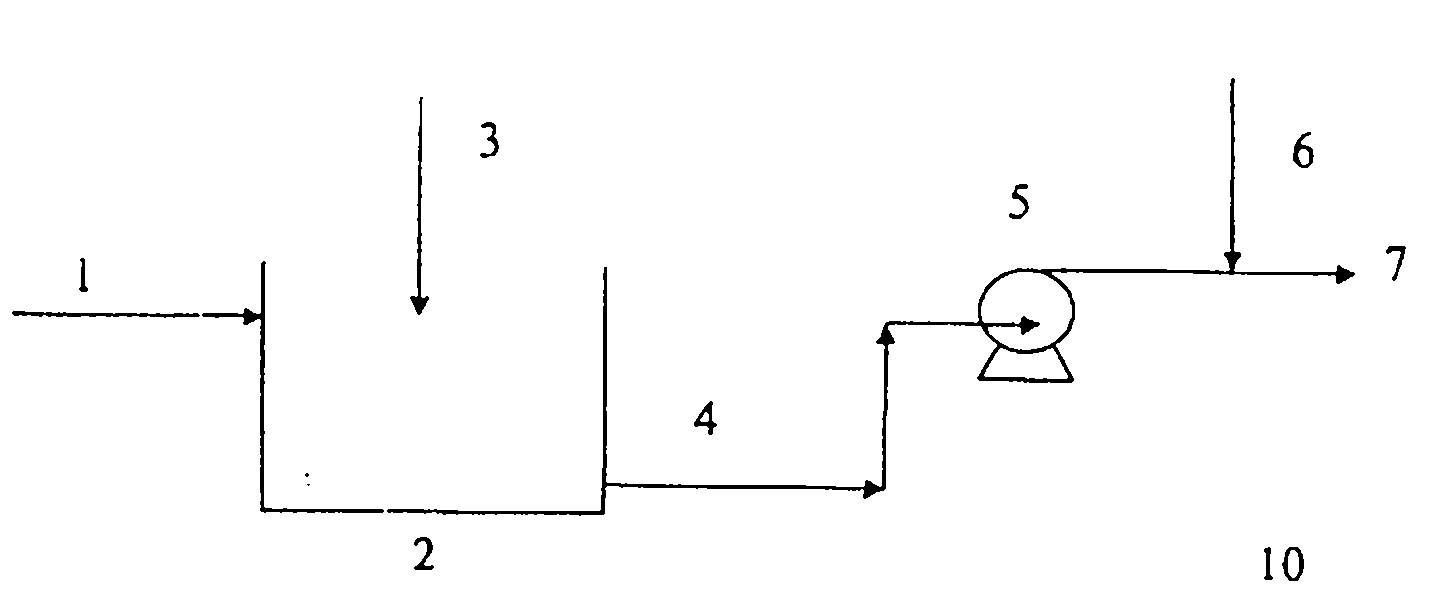

[0011] The present invention provides an improved method of lowering the pH of wastewater during chemical treatment of wastewater, the improvement comprising introducing carbon dioxide into the wastewater. The chemical treatment involves the introduction of chemical agents in the wastewater. The chemical agent is selected from the group consisting of flocculants, flocculation-supporting reagents, corrosion inhibitors and scale inhibitors.

[0012] Carbon dioxide is introduced into wastewater either before or after chemical treatment. Carbon dioxide can be introduced into wastewater at one location or at multiple locations. When the pH of the wastewater is greater than 8, carbon dioxide can be introduced into the wastewater undergoing chemical treatment. The introduction of carbon dioxide also reduces the temporary hardness of the wastewater.

[0013] The wastewater is usually from iron and steel production plants, and the wastewater can be selected from the following group:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com