High-efficiency crank connecting rod mechanism

A crank-link mechanism, high-efficiency technology, applied in the direction of the crank, connecting rod, crankshaft, etc., can solve the problems of increasing engine vibration and noise, consuming engine mechanical power, increasing design quality, etc., to reduce vibration and noise, reduce effective Mechanical work, the effect of improving mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

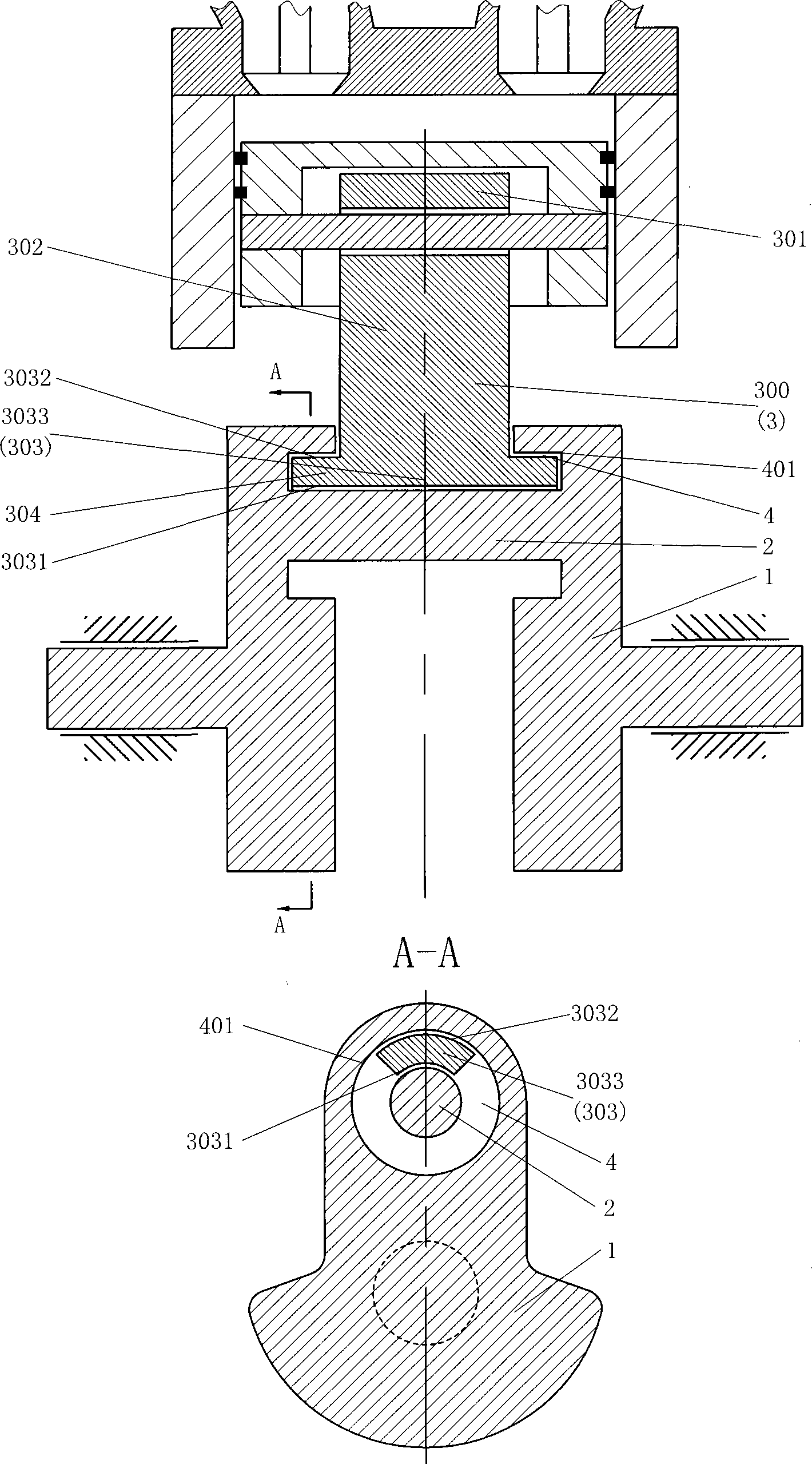

Embodiment 1

[0027] like figure 1 The high-efficiency crank-link mechanism shown includes a crank 1, a connecting rod journal 2 and a connecting rod 3. The crank 1 and the connecting rod journal 2 are integrally processed, and the crank 1 is provided with a ring around the connecting rod journal 2. Groove 4, connecting rod 3 is set as high-efficiency connecting rod 300 formed by connecting rod small head 301, connecting rod body 302 and inner and outer sides matching opening pipe wall 3033, and inner and outer sides matching opening pipe wall 3033 inner side 3031 and connecting The rod journal 2 matches. The two ends of the inner and outer sides matching the opening pipe wall 3033 are set as the pipe wall fitting end 304, and the pipe wall fitting end 304 is arranged in the annular groove 4, and the inner side 3031 of the pipe wall fitting end 304 is matched with the connecting rod journal 2, and the pipe wall The outer surface 3032 of the mating end 304 is matched with the inner surface ...

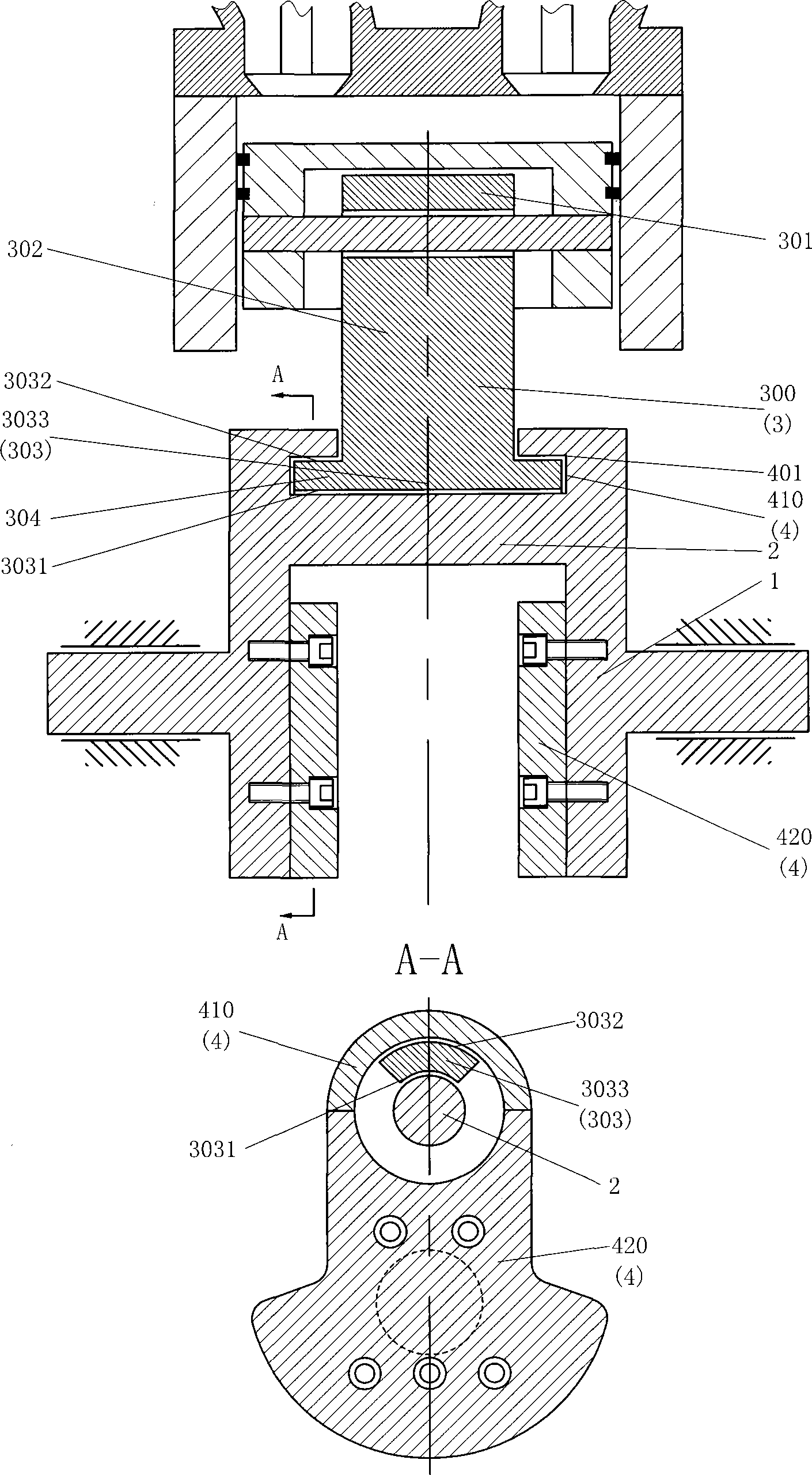

Embodiment 2

[0029] like figure 2 The difference between the shown high-efficiency crank-link mechanism and Embodiment 1 is that the annular groove 4 is set to be formed by the first semi-annular body 410 and the second semi-annular body 420; 1 is integrally processed, and the second semi-annular body 420 is set to be fixedly connected with the crank 1.

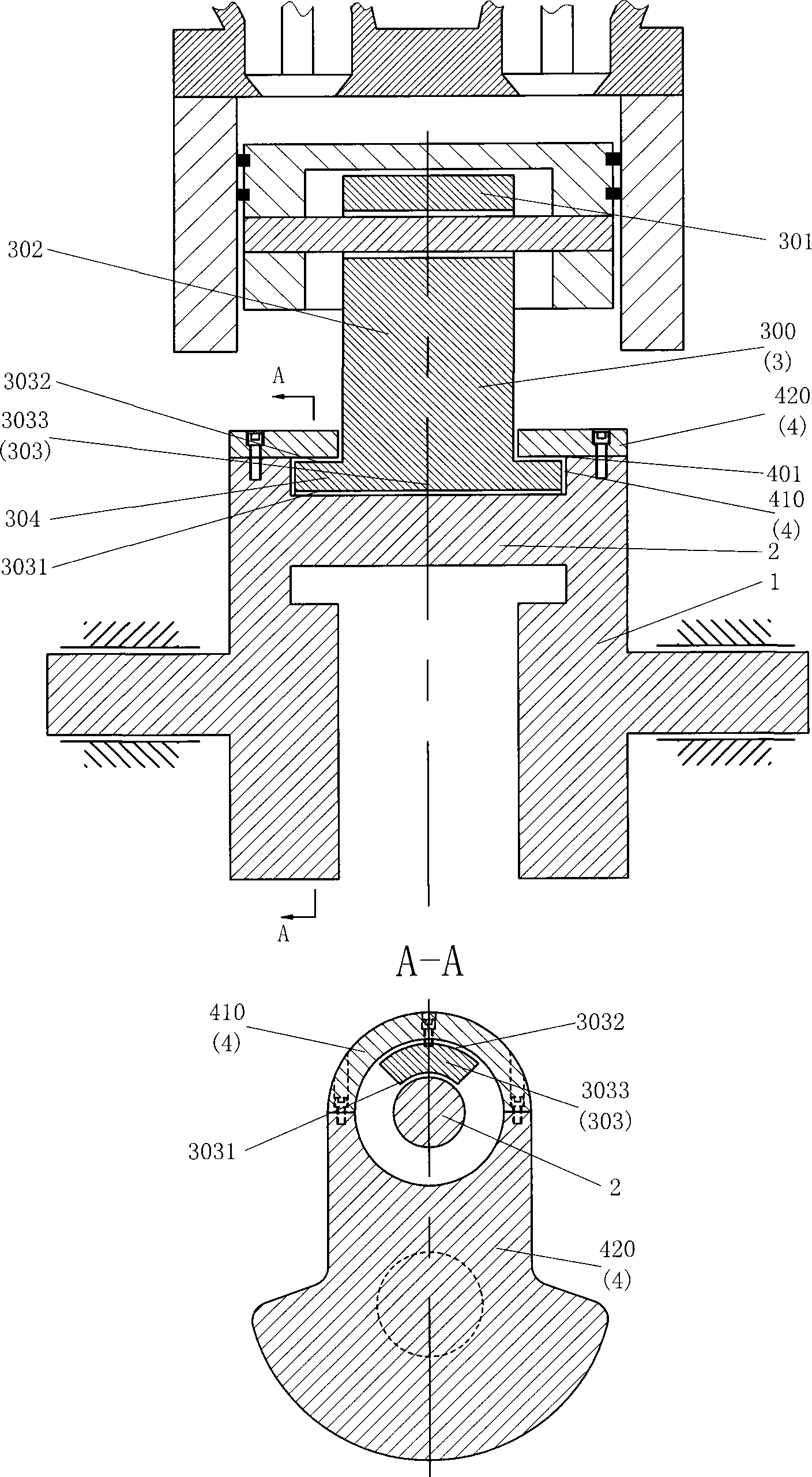

Embodiment 3

[0031] like image 3 The difference between the shown high-efficiency crank-link mechanism and Embodiment 1 is that the annular groove 4 is set to be formed by the first semi-annular body 410 and the second semi-annular body 420; 1 is fixedly connected, and the second semi-annular body 420 is set to be integrally processed with the crank 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com