Gas sampling method and device

A gas sampler and re-sampling technology, which is applied in the direction of sampling device, test sample preparation, etc., can solve the problems of sampling itself, difficulty in obtaining gas samples, and large loss of sampling needles, so as to avoid interference and provide accuracy , The effect of reducing equipment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

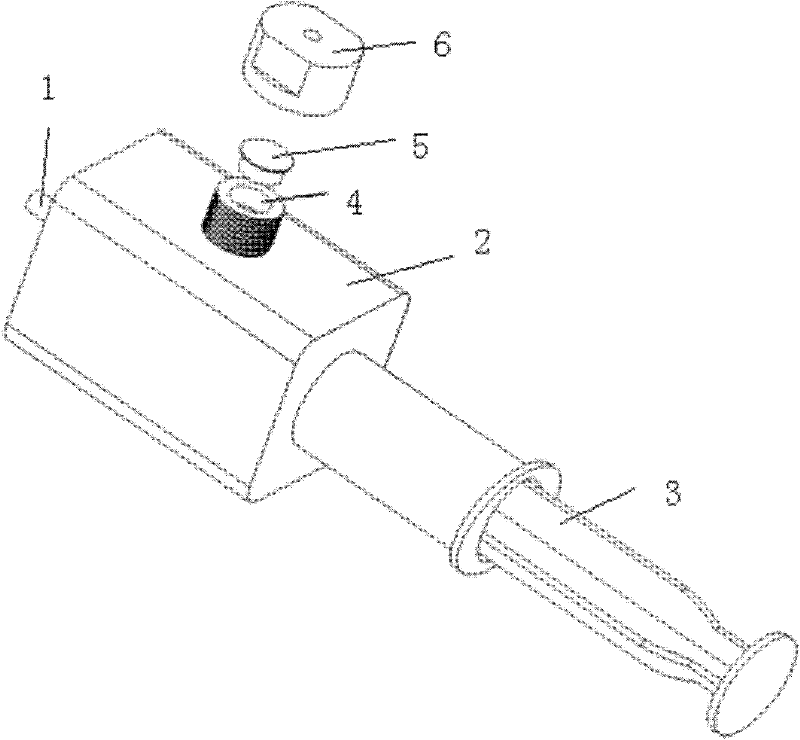

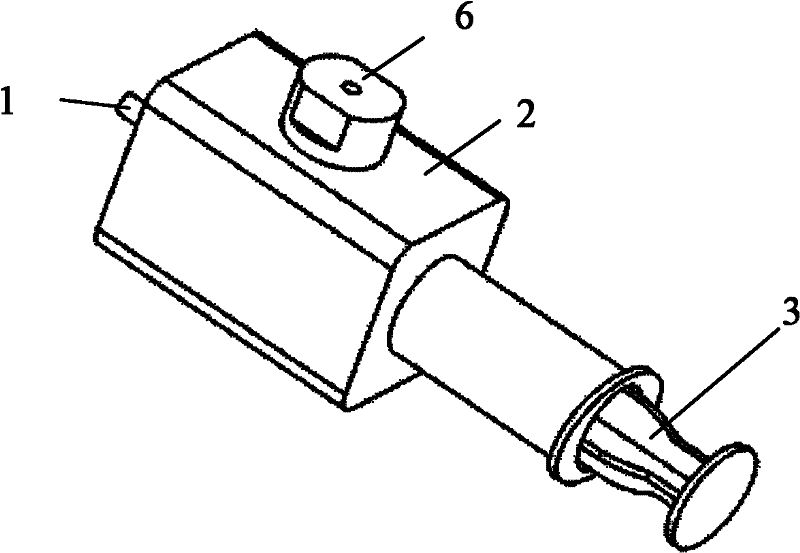

[0034] Such as figure 1 The gas sampler includes a sampling needle 1 and a gas collection cylinder 2, the gas collection cylinder 2 includes a sampling port (not shown in the figure) arranged at the end of the gas collection cylinder body, and one end is inserted into a suction / The exhaust push rod 3 and the secondary sampling port 4 provided on the wall of the gas collector, the secondary sampling port 4 is sealed by a sealing device (the present embodiment adopts a rubber gasket, and of course other materials with good elasticity can also be used. similar material), the sampling needle 1 is installed on the sampling port, and the hardness of the sampling needle 1 is greater than that of the explosion-proof ball in the corresponding battery. Because the positive hole of the Ni-MH battery is small, it is difficult to align, easy to stick off, and the explosion-proof ball is relatively hard, use a small, not hard sample needle to directly insert into the positive hole to sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com