Electrophotographic photoreceptor, process cartridge and image forming apparatus

A technology for electrophotography and photoreceptors, which is applied in the field of process boxes, image forming equipment, and electrophotographic photoreceptors. It can solve the problems of photoreceptor scratches, photoreceptor deterioration, wear, and punctures, and achieve the suppression of uneven concentration and weight loss. shadow, high mechanical strength effect

Inactive Publication Date: 2010-09-29

FUJIFILM BUSINESS INNOVATION CORP

View PDF12 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the related art described above, there have been problems of deterioration and abrasion of the photoreceptor due to the use of the contact charging method and scratches of the photoreceptor and poking of foreign objects due to the use of the contact charging method and an intermediate transfer medium.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

Synthetic example 1

Synthetic example 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Login to View More

Abstract

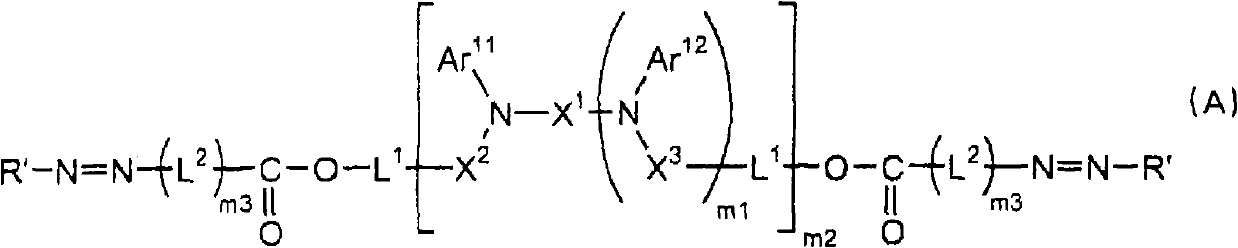

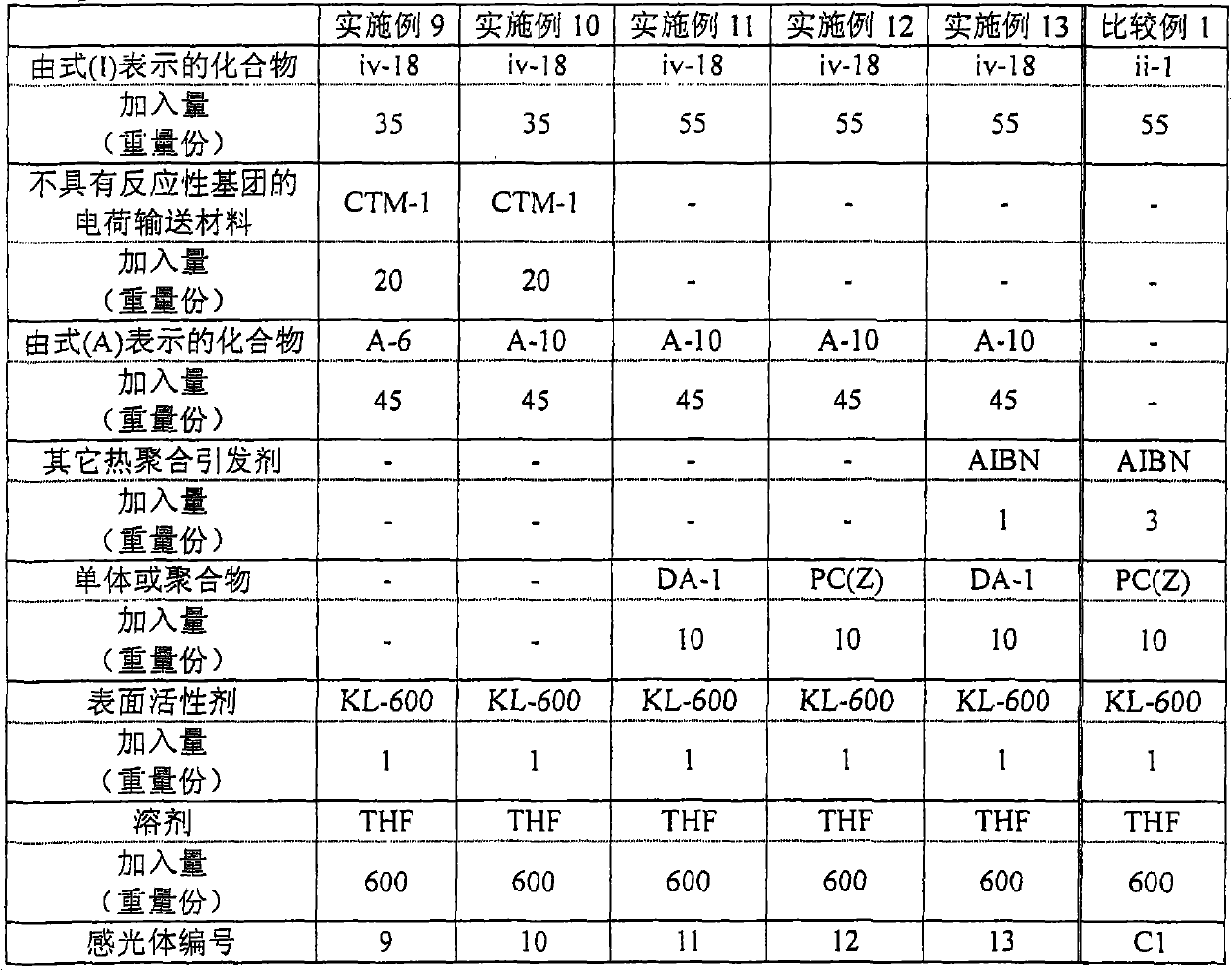

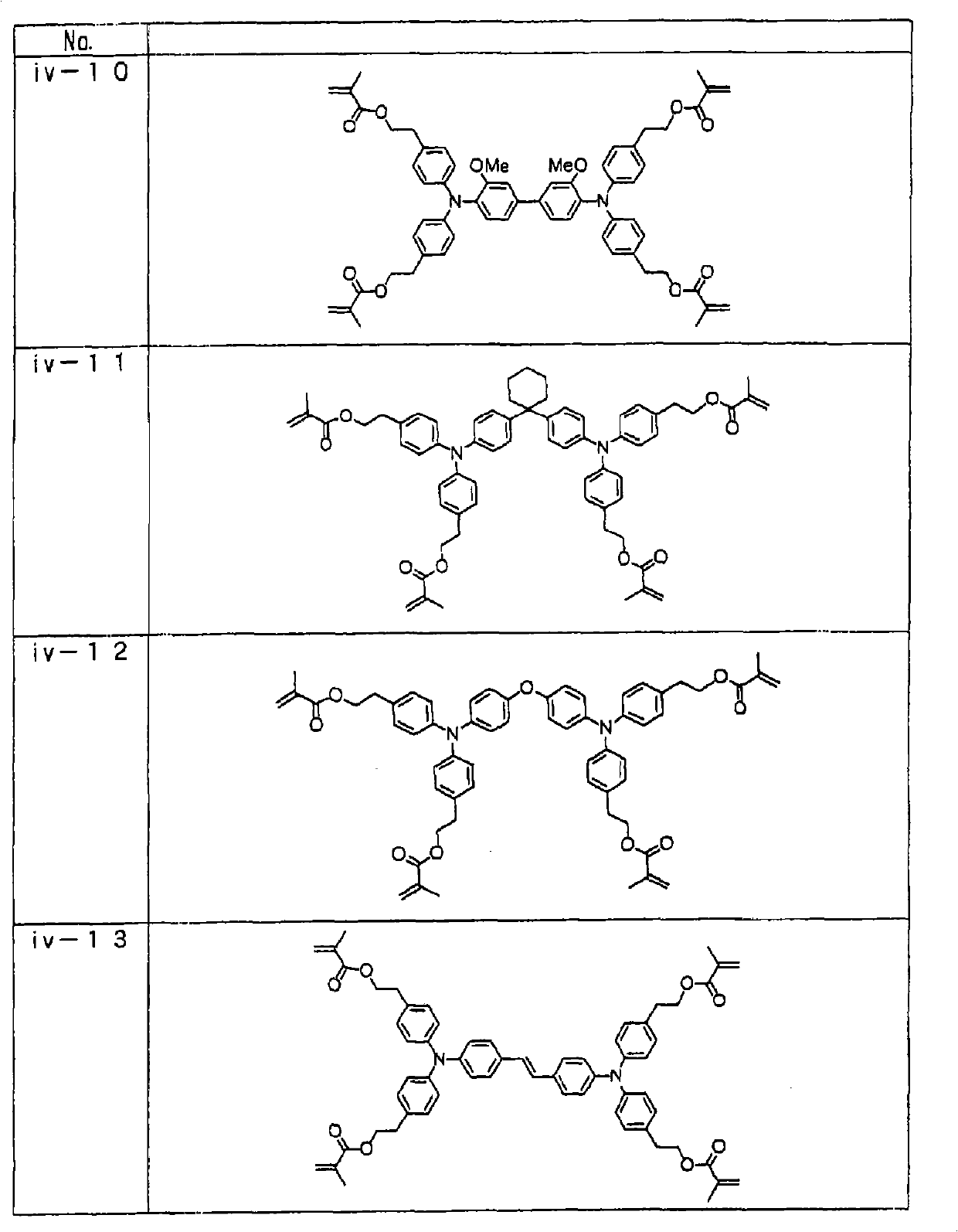

The invention relates to an electrophotographic photoreceptor, a process cartridge and an image forming apparatus, and aims to provide an electrophotographic photoreceptor having an outermost surface with high mechanical strength and can restrain thickness nonuniform and image ghost for long. The electrophotographic photoreceptor comprising: a conductive substrate; a photosensitive layer formed on the conductive substrate; and an outermost surface layer that is a layer made of a cured material of a composition including at least one compound represented by the following formula (I) and at least one compound having charge transportability and an azo group: wherein in formula (I), F represents an n-valent organic group having a hole transporting property, R represents a hydrogen atom or an alkyl group, L represents a divalent organic group, n represents an integer of 1 or more, and j represents 0 or 1.

Description

technical field The present invention relates to an electrophotographic photoreceptor, a process cartridge, and an image forming apparatus. Background technique Generally, an electrophotographic image forming apparatus has the following structure and steps. Specifically, the image-formed product is obtained by charging the surface of the electrophotographic photoreceptor with a charging unit to impart a desired polarity and potential to the surface; exposing the surface to light to selectively decharge the surface, thereby forming an electrostatic latent image on the surface; attaching toner to the latent image by a developing unit, thereby developing the latent image to form a toner image; The toner image is transferred onto an image-receiving medium by a transfer unit. In recent years, electrophotographic photoreceptors have been more frequently used in copiers, laser printers, and the like because of their advantages in providing high-speed and high-quality printing. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G03G5/147G03G21/18G03G15/01

CPCG03G5/076G03G5/14795G03G2215/00957G03G5/14791G03G5/14786G03G5/14769G03G5/075G03G5/0766G03G5/0764G03G5/0765

Inventor 山田涉额田克己岩崎真宏平野明土井孝次

Owner FUJIFILM BUSINESS INNOVATION CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com