Biaxially stretched polypropylene film for capacitor, deposition-coated film obtained from the same, and capacitor employing the same

A polypropylene film, biaxial stretching technology, applied in the direction of fixed capacitor dielectric, capacitor, fixed capacitor, etc., to achieve the effects of excellent resistance, excellent processing adaptability, and excellent dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

no. 2 approach

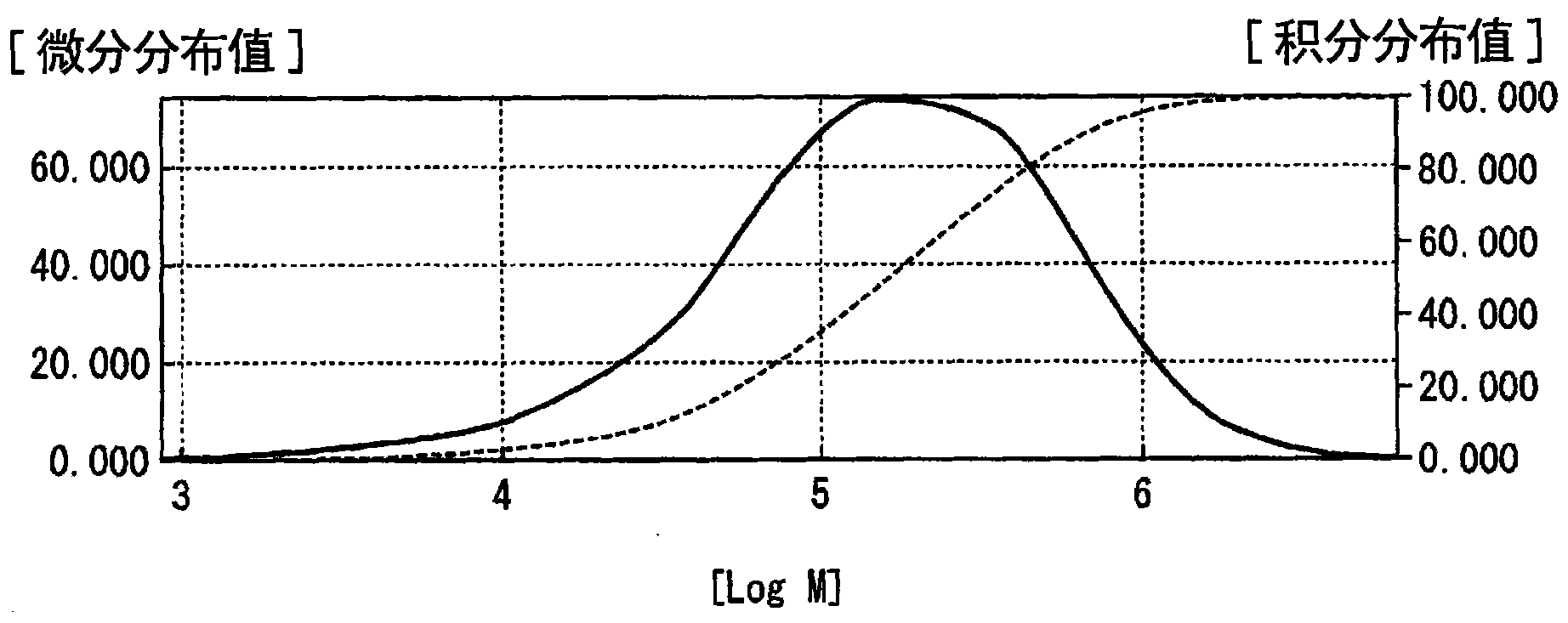

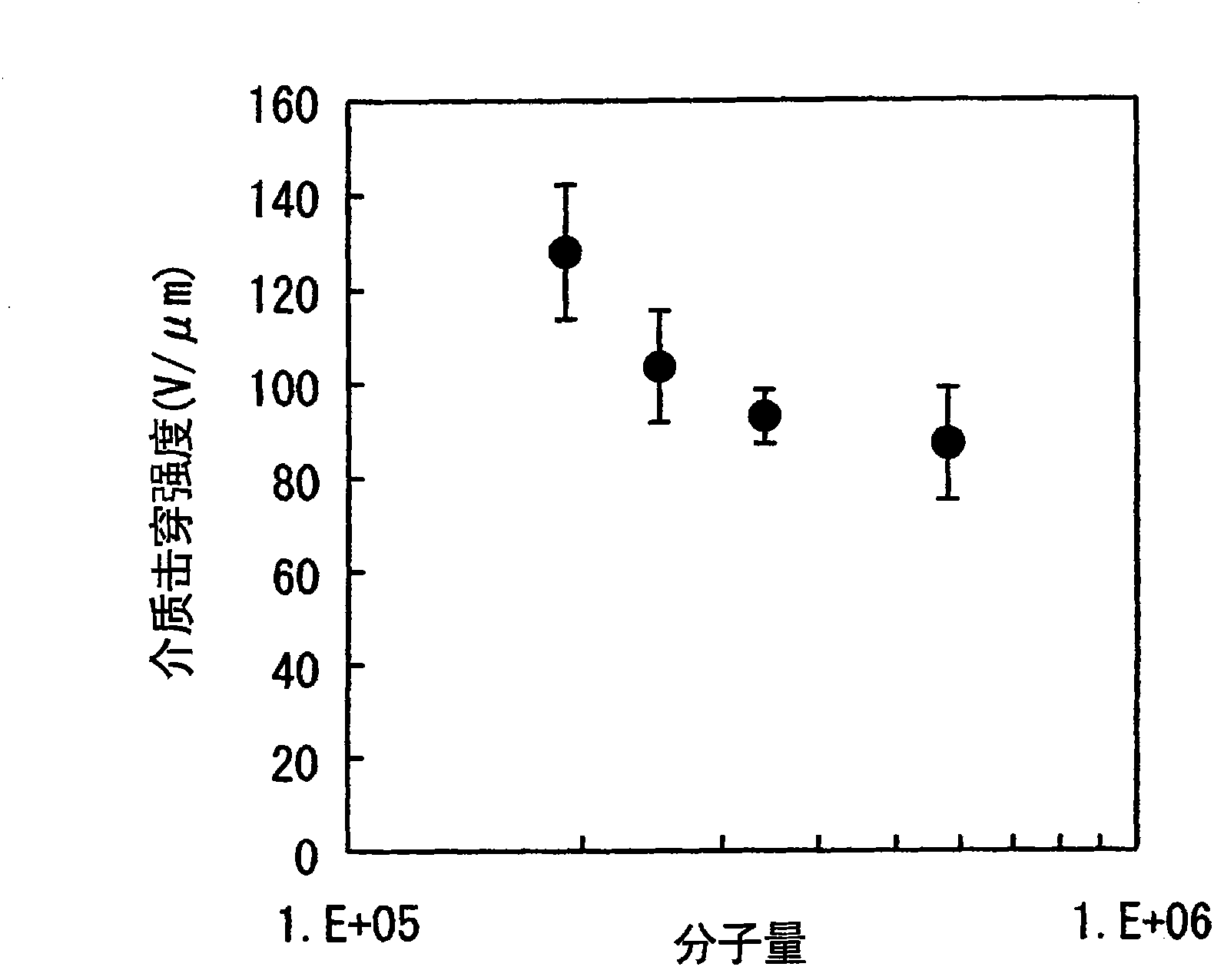

[0104] The molecular characteristics (molecular weight, molecular weight distribution, composition of molecular weight distribution, tacticity) of the biaxially stretched polypropylene film of the first or second embodiment (hereinafter referred to as the present embodiment) are not values of the resin itself for film production , must be the value of the resin that formed the thin film after the film forming process. Such a resin formed into a film undergoes a lot of thermal and oxidative deterioration, shear deterioration, elongation deterioration, etc. in the extruder during the film forming process, and a lot of thermal and oxidative deterioration occurs in the stretching process. , elongation deterioration, etc., thus aggravating the decomposition. Along with this, the molecular weight, molecular weight distribution, and tacticity are often different between the raw material resin and the film-forming resin after film formation. It is a molecular characteristic of the ...

Embodiment 1

[0202]Resin A pellets manufactured by Company A are supplied to an extruder, melted at a resin temperature of 250°C, extruded through a T-die, wound up on a metal drum whose surface temperature is kept at 95°C, and solidified. A cast green sheet having a thickness of about 250 μm was produced. Next, the unstretched cast green sheet was stretched to 5 times in the longitudinal direction at a temperature of 140° C., immediately cooled to room temperature, and then stretched to 10 times in the transverse direction at a temperature of 165° C. with a tenter, A thin biaxially stretched polypropylene film with a thickness of 5.0 µm was obtained. The molecular properties and melting points of the obtained films are summarized in Table 1, and the evaluation results are also summarized in Table 3.

Embodiment 2

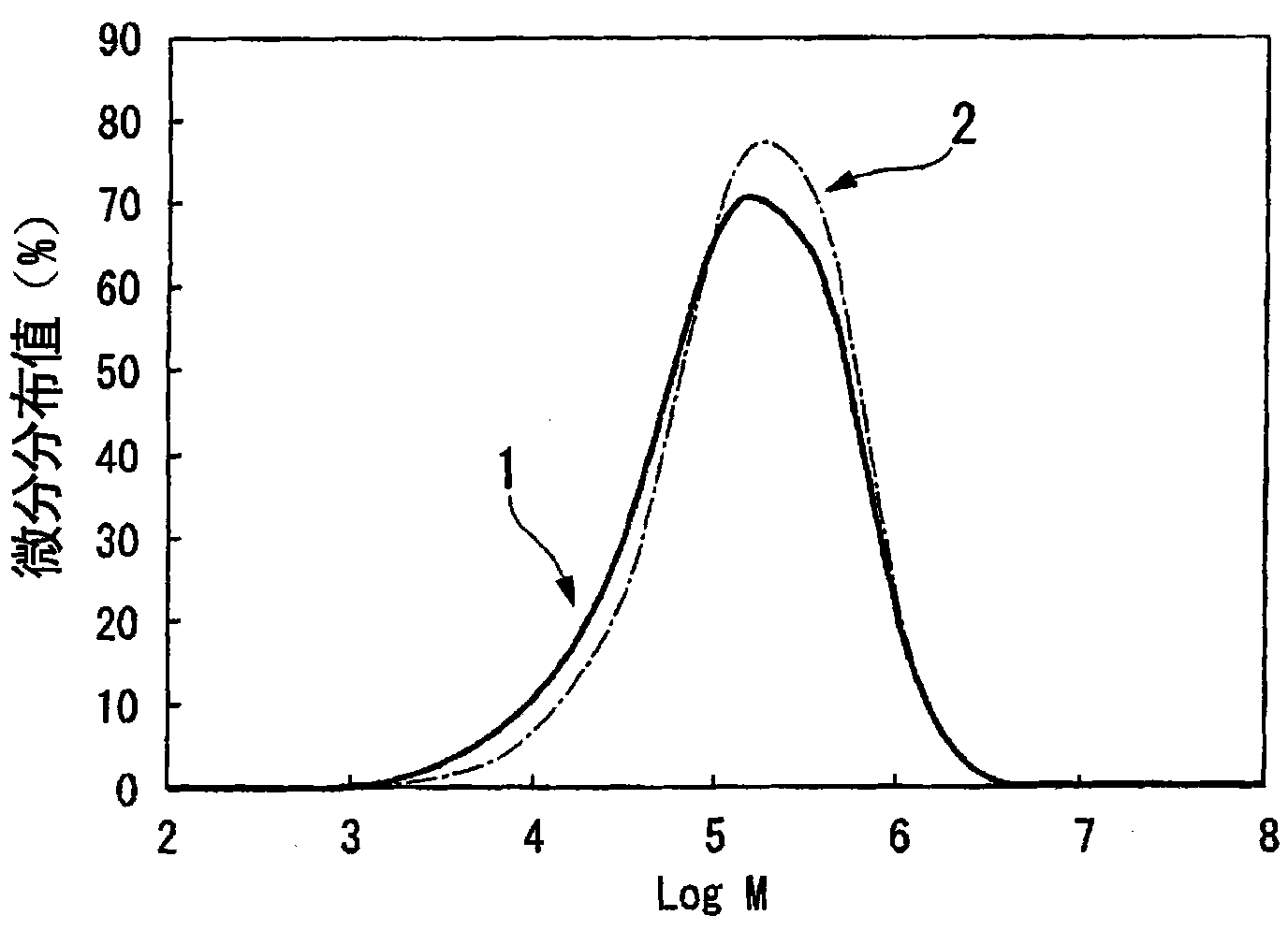

[0210] The evaluation of the film obtained from the molecular characteristics of Example 1 is within the practically preferred range, but in order to further improve the mechanical thermal stability and high-temperature withstand voltage characteristics, a resin A based on resin A that maintains tacticity was used. In the case of Resin E manufactured by Company C, obtained by further adjusting the structure of the molecular weight distribution by a polymerization method, a biaxially stretched polypropylene film was produced by the following method.

[0211] Resin E pellets manufactured by Company C were supplied to an extruder, melted at a resin temperature of 250°C, extruded using a T-die, wound up on a metal drum whose surface temperature was kept at 90°C, and solidified. A cast green sheet having a thickness of about 250 μm was produced. Next, the unstretched cast green sheet was stretched to 5 times in the longitudinal direction at a temperature of 140° C., immediately coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com