Strip break on-line detection method of acid pickling-rolling mill integral unit

A technology that combines units and detection methods, applied in mechanical bearing testing, metal rolling, length measuring devices, etc., can solve problems such as difficulty in coordinated control and easy failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

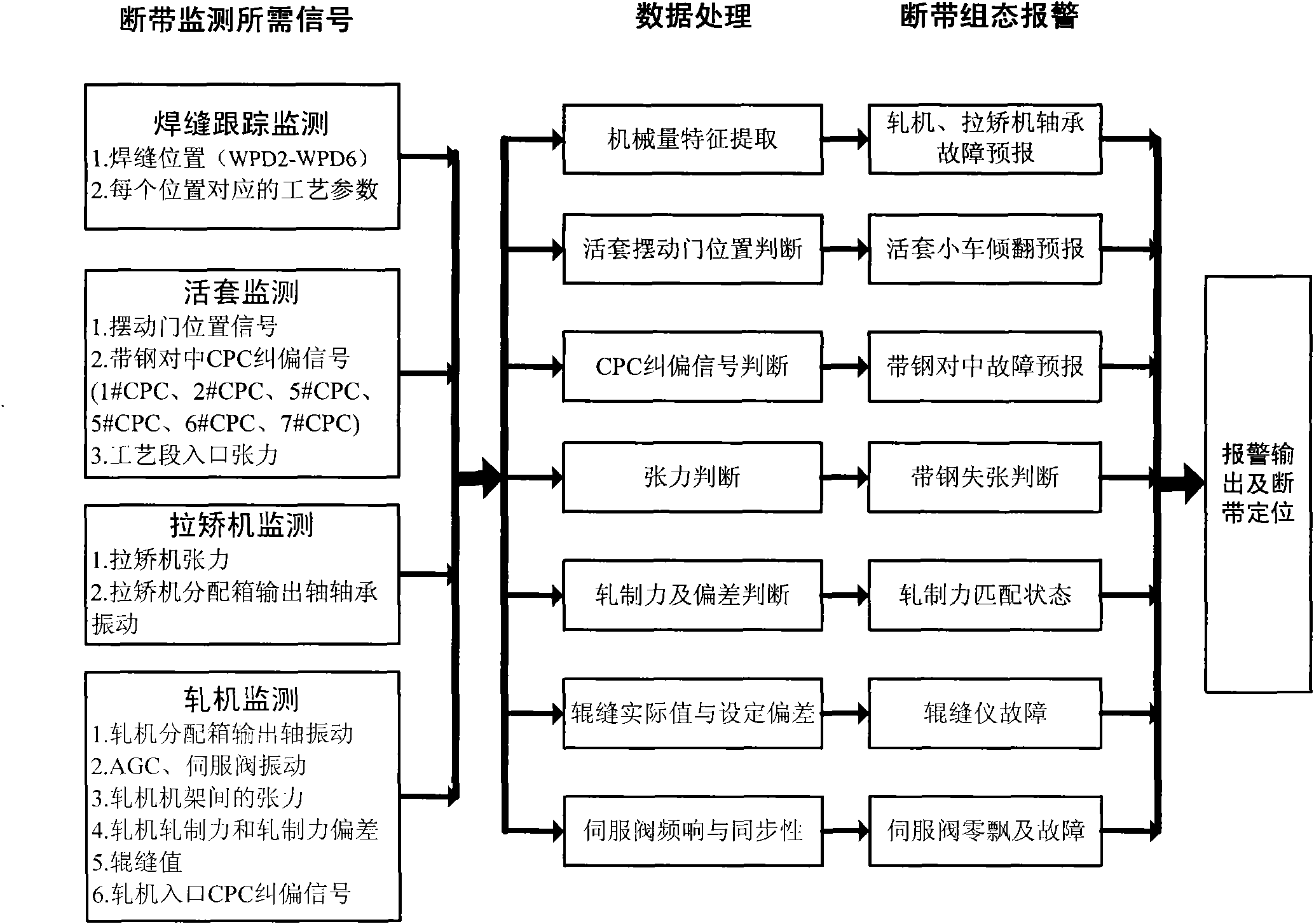

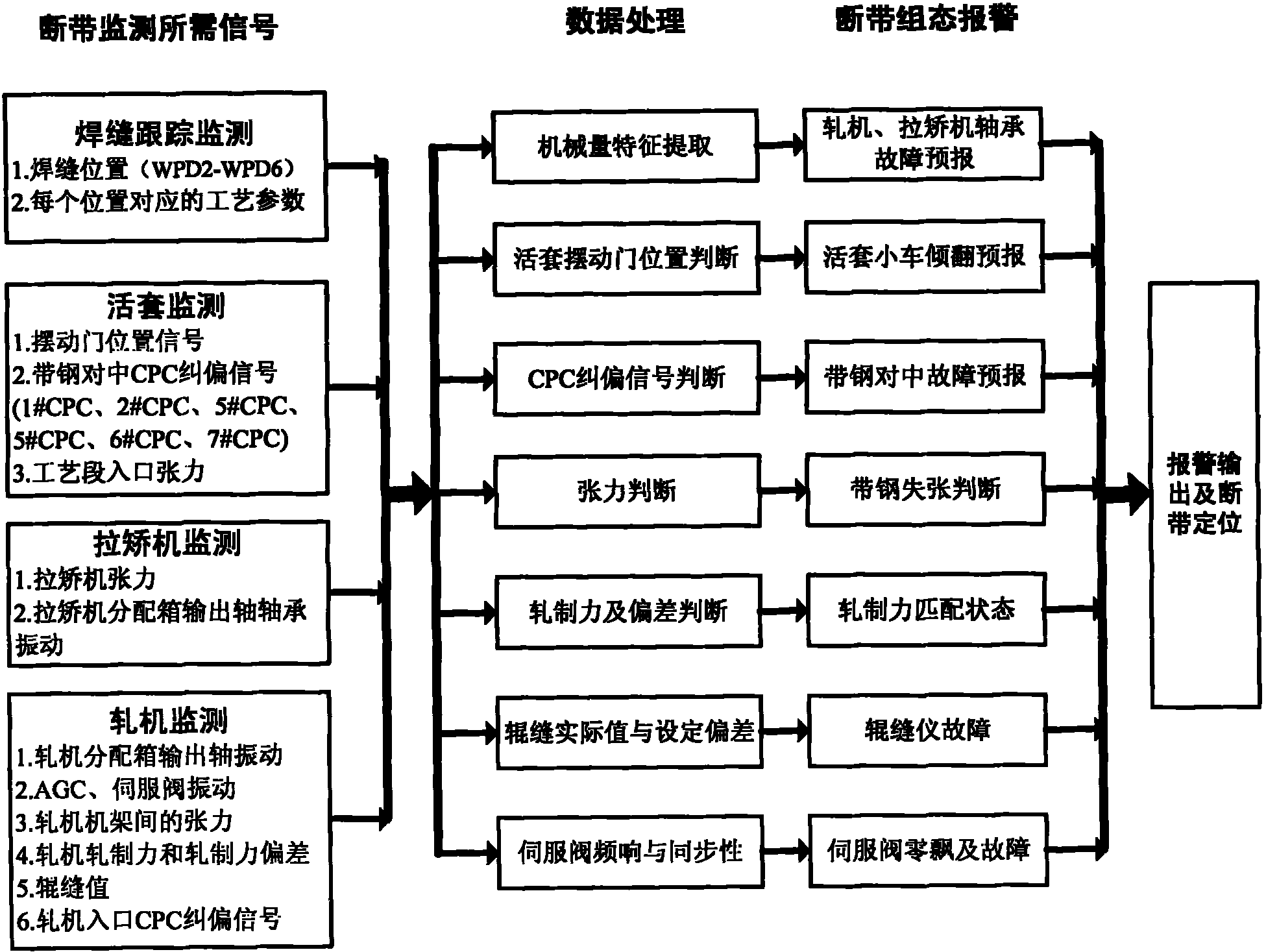

[0056] Such as figure 1 As shown, the present invention is aimed at the process characteristics and failure history of the combined pickling and cold rolling unit, and the on-line monitoring scheme of the broken strip of the combined pickling and cold rolling unit is emphatically carried out from the following aspects:

[0057] (1) Seam tracking and monitoring

[0058] A total of 6 welding seam tracking points WPD1-WPD6 are set up in the pickling mill. When the welding passes through each position, the process parameters need to be adjusted according to the incoming materials and rolling specifications according to the process requirements. The weld detector is used to track the position of the strip steel Each time the weld signal is received, the strip tracking software will perform a synchronous correction of the strip length so as to accurately track the weld position of the strip.

[0059] (2) Loop broken belt monitoring

[0060] The function of the looper is to adapt t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com