Fired mold and precision casting process utilizing same

A technology of investment mold and casting, which is applied in the field of precision casting technology and investment mold, can solve the problems of insufficient pouring, low product pass rate, unsmooth ventilation, etc., and achieve the effect of good casting quality, high yield rate and sufficient pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

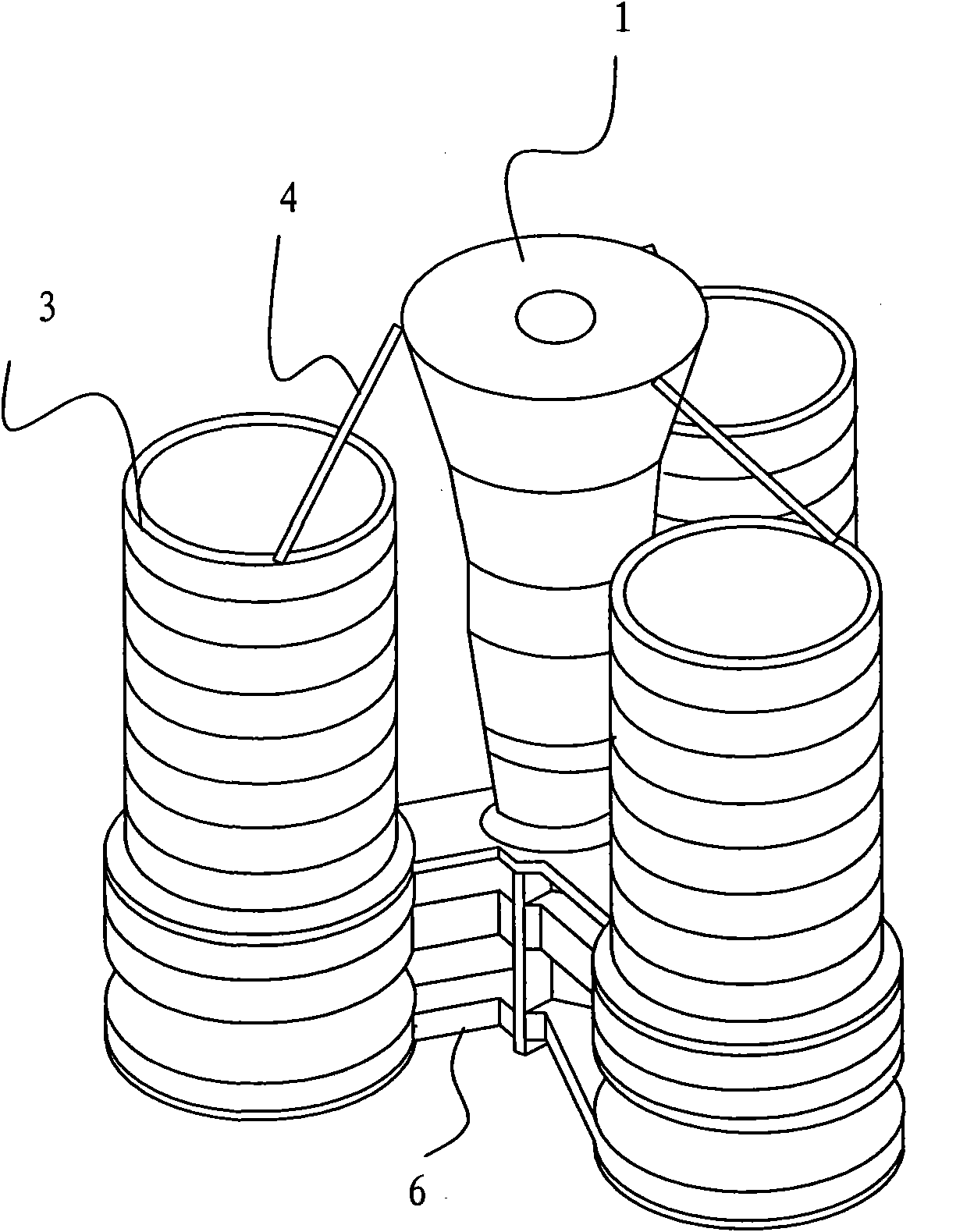

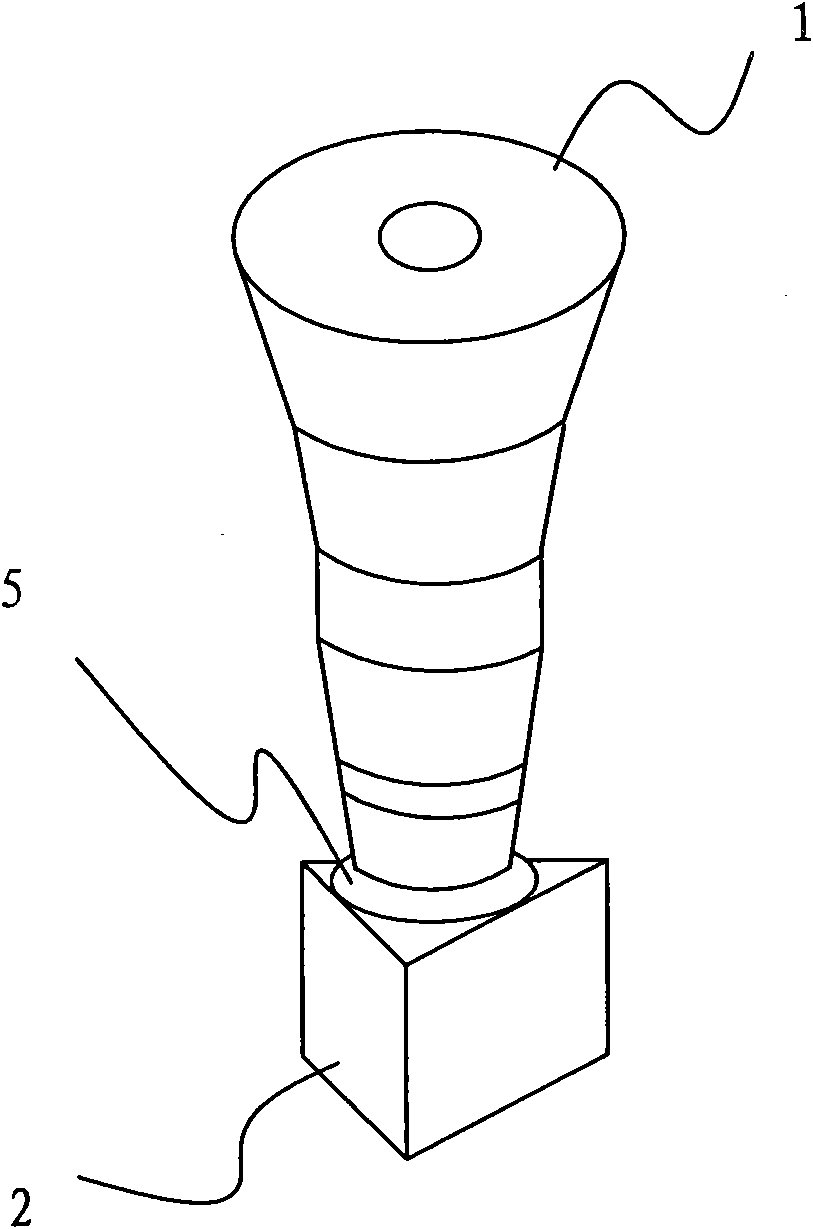

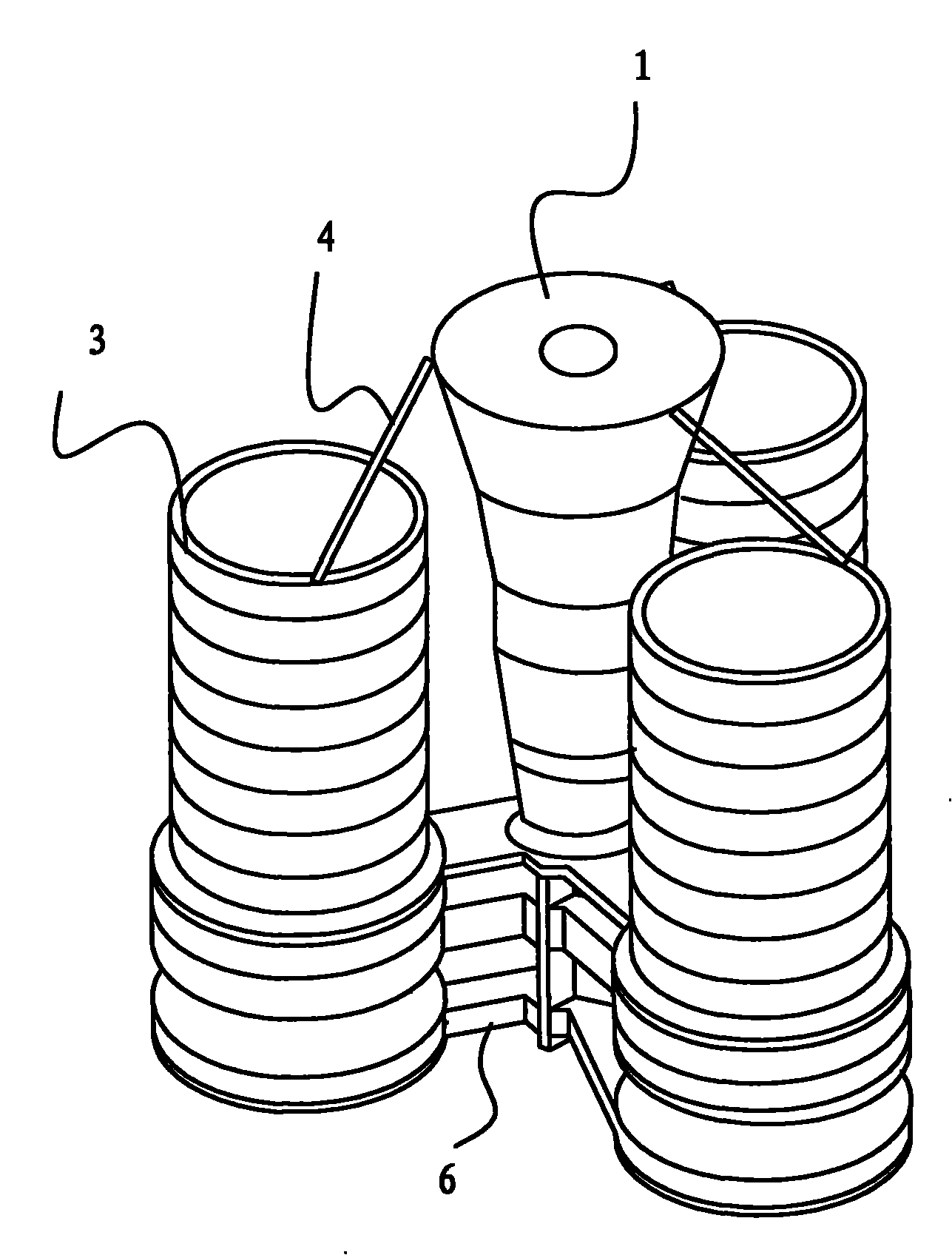

[0022] As shown in the figure, an investment mold for casting quick joints includes a trumpet-shaped pouring body 1, and the bottom end of the pouring body 1 expands radially downwards gradually to form a feeding body 5, which is connected to a triangular prism-shaped mold There are three casting bodies 3 evenly distributed around the casting body 1. Of course, the shape of the die head 2 and the number of casting bodies 3 can be changed, but it must be satisfied that the die head 2 is a column with a positive multi-deformation cross section. body, to ensure that the casting body 3 is evenly distributed, so that they dissipate heat evenly, and there is no difference in products.

[0023] The casting body 3 has the same shape as the quick connector to be cast, and of course the casting body 3 can also be in other shapes. When it is tubular, the length is 10-50 cm, the outer diameter is 5-30 cm, and the cross-sectional shape can be arbitrary. The ratio of the distance between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com