Numerical control plasma torch cutting anti-collision device

An anti-collision and plasma technology, applied in the direction of plasma welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of poor protection ability, inaccurate reset, inflexible movement, etc., and achieve compact structure, accurate positioning, and no maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to solve the problem that the cutting torch of the plasma cutting machine is not damaged after being collided during the working process, and the machining accuracy is not affected, an anti-collision self-protection device for the cutting torch is designed.

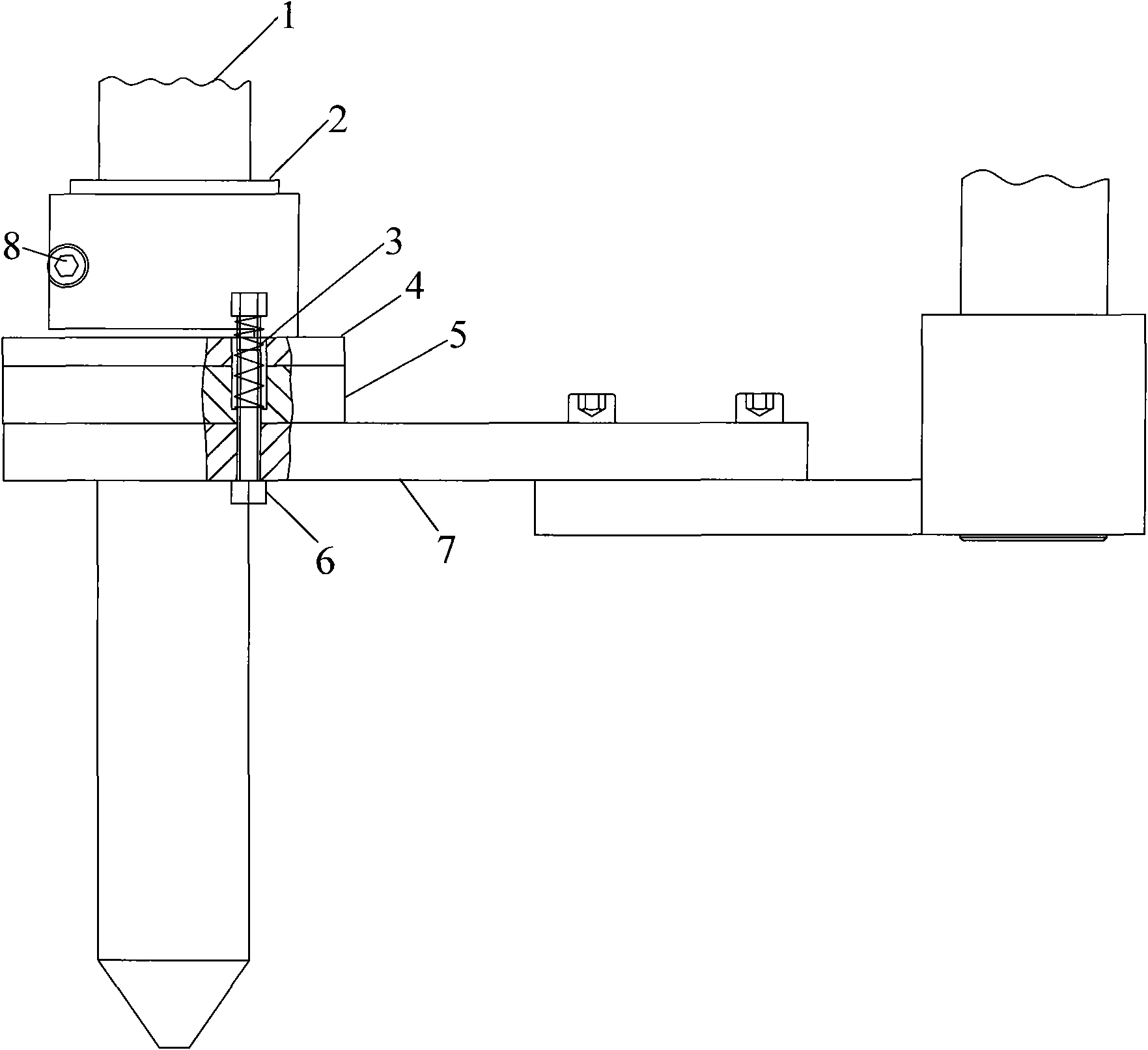

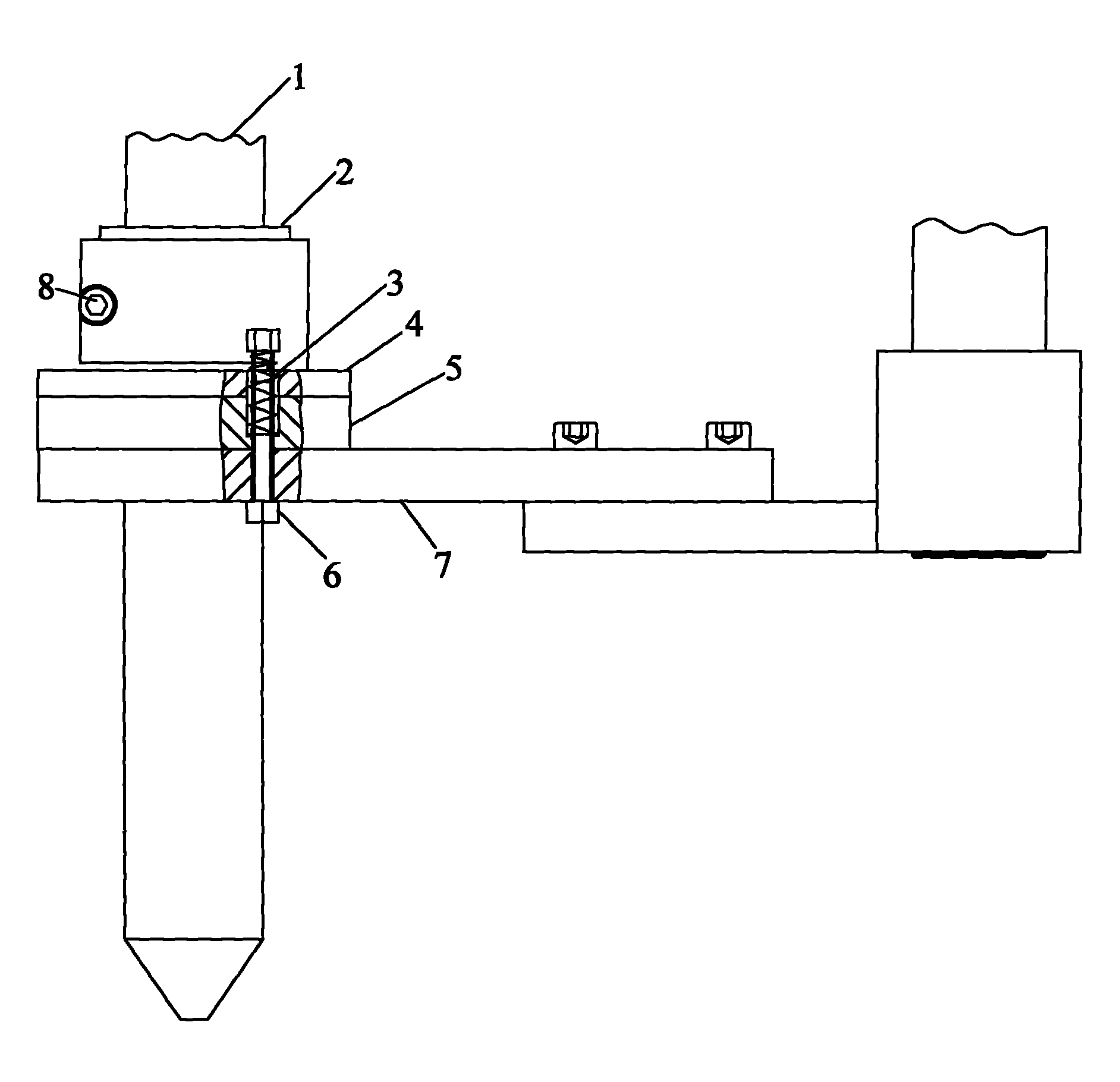

[0015] like figure 1 As shown, the CNC plasma cutting torch anti-collision device includes a gun holster 2, a spring 3, a fixed seat 4, a positioning block 5 and a cutting gun bracket 7. The fixed seat 4 is provided with a spring positioning hole, and the positioning block 5 is provided with a countersunk head The upper hole of the countersunk head hole is a spring positioning hole, the lower hole of the countersunk head hole is a bolt positioning hole, and the bracket 7 is provided with a bolt positioning hole; the cutting gun 1 is placed in the hole of the gun holster 2, and the gun holster 2 is accommodated in the hole. In the fixed seat 4, the fixed seat 4 is installed on the positioning block 5, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com