In-built component for automobile

A technology for interior decoration and automobiles, which is applied to vehicle parts, transportation and packaging, and vehicle safety arrangements, etc. It can solve the problems of larger and larger reaction forces, and achieve the effects of reducing reaction forces, reducing loads, and good energy absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

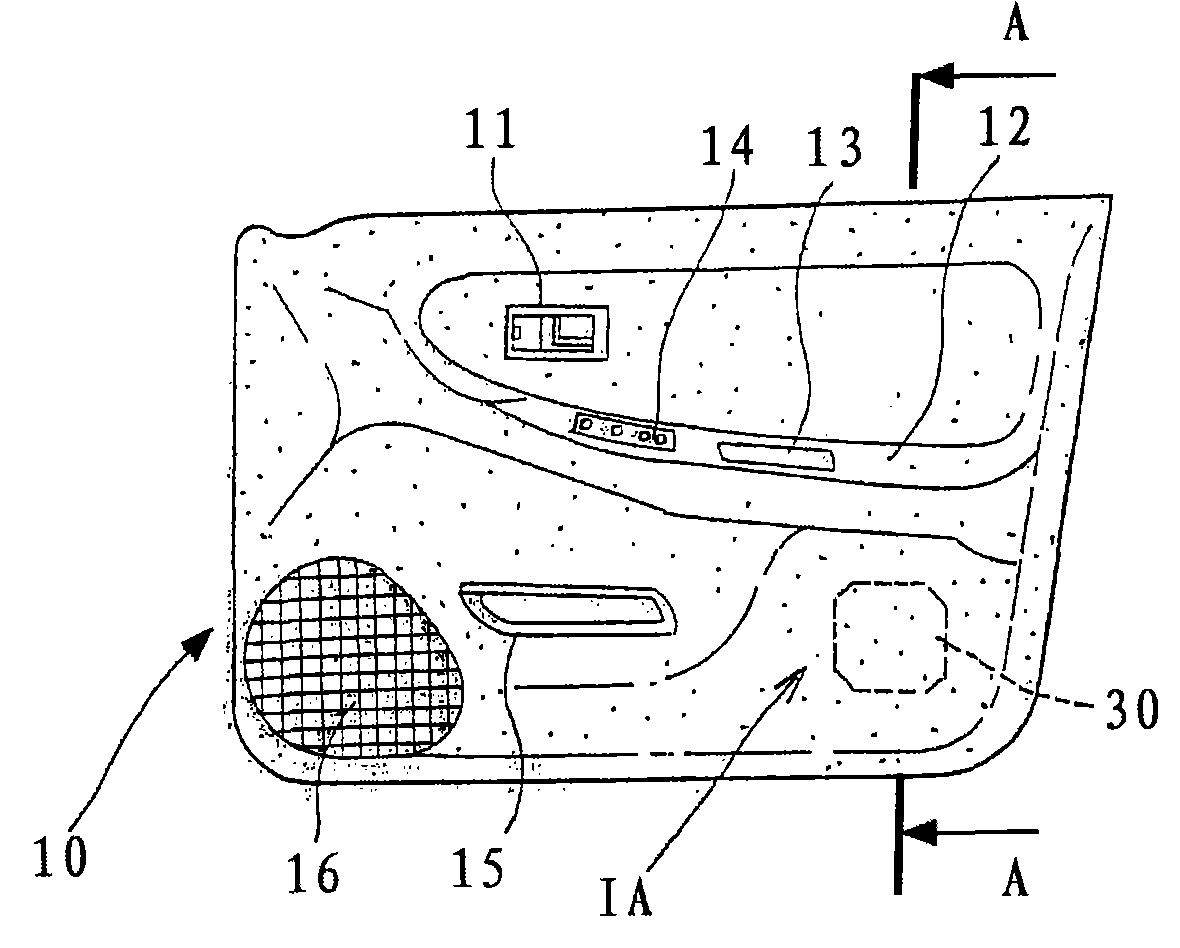

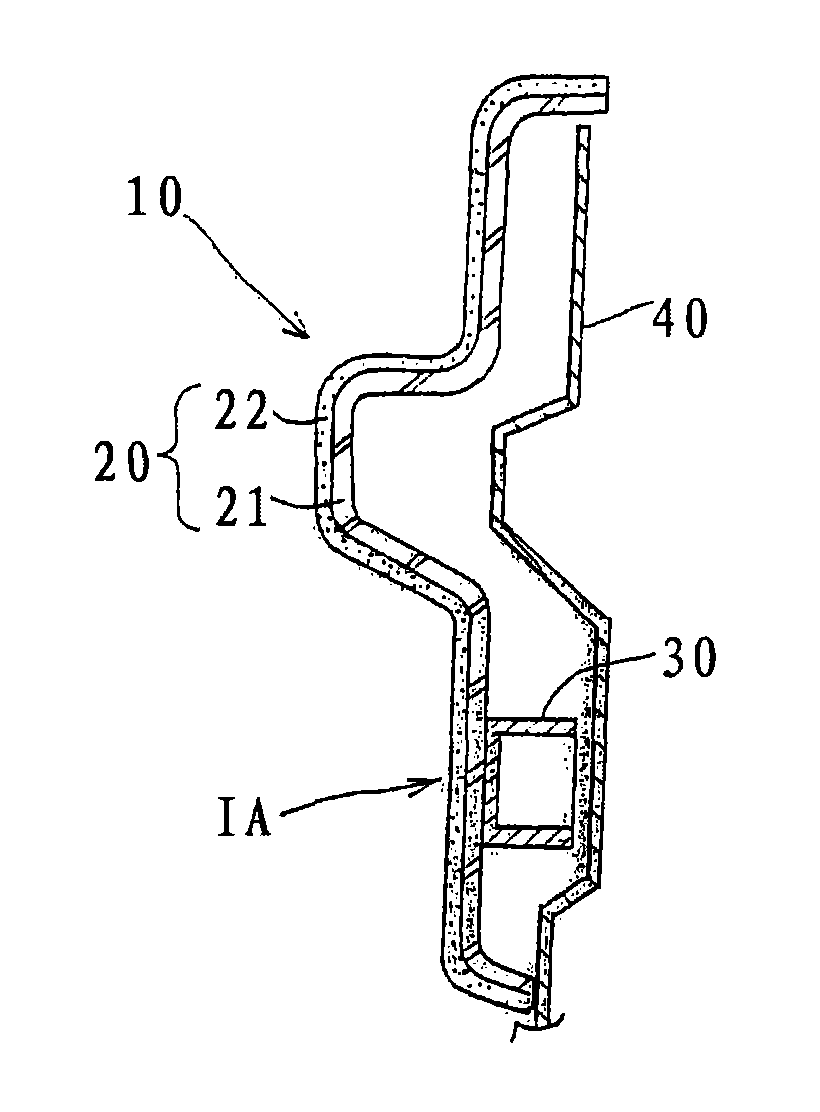

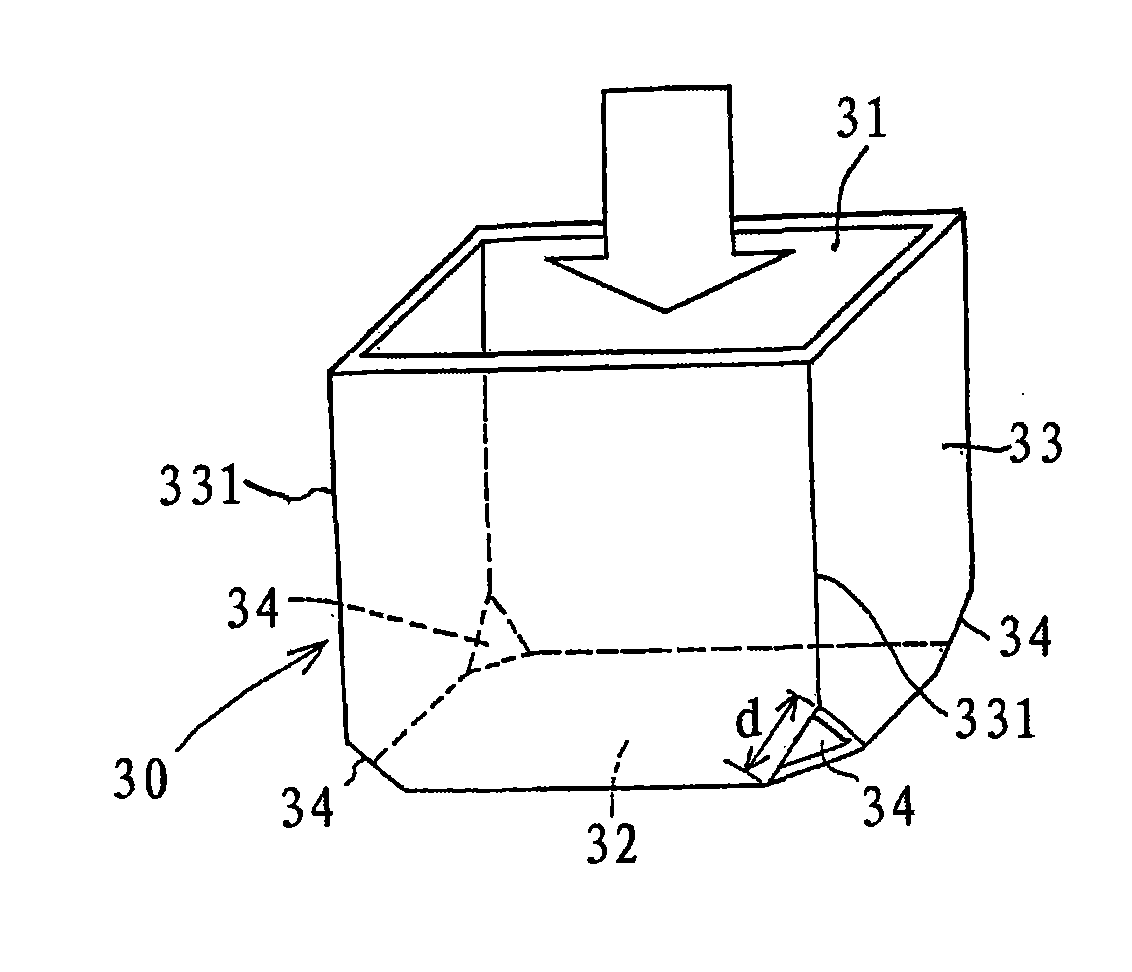

[0097] Figure 1 to Figure 5 It is a drawing showing the first embodiment of the present invention. figure 1 To represent the front view of the door trim panel for automobiles to which the present invention is applied, figure 2 is a cross-sectional view showing the structure of the door trim panel for an automobile, image 3 It is an explanatory drawing showing the shock absorber provided in the door trim panel for the automobile, Figure 4 is an explanatory diagram of a test method for measuring the impact absorbing performance of the impact absorber, Figure 5 It is a graph showing the correlation of reaction force / intrusion amount of the shock absorber. in addition, Image 6 , Figure 7 A modification of the first embodiment of the present invention is shown in which, Image 6 It is a perspective view showing the structure of the shock absorber applicable to the present invention, Figure 7 It is a graph showing the impact absorption performance of the impact absor...

Embodiment 2

[0111] Figure 10 to Figure 19 is a diagram showing a second embodiment according to the present invention. Figure 10 is a sectional view showing the structure of a door trim panel for an automobile, Figure 11 is a perspective view showing an impact absorber attached to the door trim panel for the automobile, Figure 12 It is an explanatory diagram showing the impact absorption performance of the door trim panel for an automobile, Figure 13 It is a graph showing the impact absorption performance of the impact absorber. in addition, Figure 14 to Figure 19 is a diagram showing a modified example of the second embodiment of the present invention, wherein, Figure 14 is a perspective view showing a shock absorber, Figure 15 is a graph showing the impact absorbing performance of the impact absorber, Figure 16 is a perspective view showing another impact absorber, Figure 17 is a graph showing the impact absorbing performance of the impact absorber, Figure 18 is a per...

Embodiment 3

[0119] Figure 20 to Figure 28 is a diagram showing a third embodiment according to the present invention. Figure 20 is a cross-sectional view showing the installation structure of the impact absorber of the door trim panel, Figure 21 (a) and (b) are a perspective view and a cross-sectional view respectively showing the structure of the impact absorber, Figure 22 is an explanatory diagram showing the action of the impact absorber, Figure 23 It is a cross-sectional view showing the bending state of the shock absorber during a side collision, Figure 24 is a graph showing the impact absorption performance of the door trim panel. Figure 25 to Figure 28 It is a diagram showing a modified example of the shock absorber applied to the third embodiment of the present invention. Figure 25 It is an explanatory diagram showing a modified example in which an inclined surface is processed on the engaging groove, Figure 26 , Figure 27 A diagram showing a modified example in wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com