Method for preparing sodium glycerophosphate

A technology of sodium glycerophosphate and glycerin, which is applied in the field of chemical medicine, can solve the problems of low content of β-sodium glycerophosphate and lack of pharmaceutical activity of α-sodium glycerophosphate, and achieve proper ratio of raw materials, reduce production costs, and process parameters reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

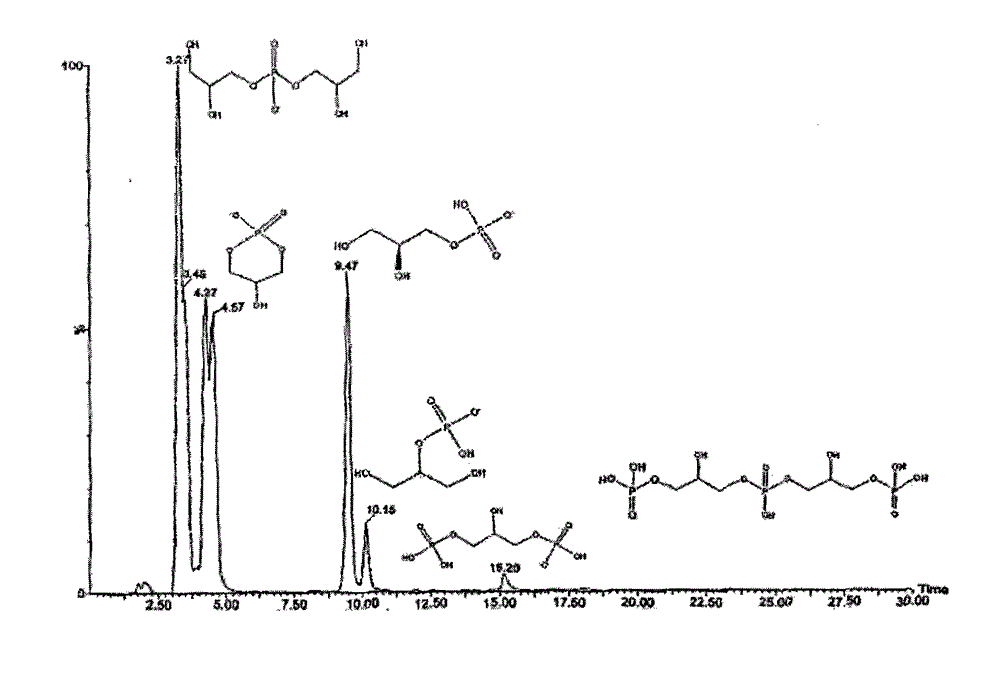

Image

Examples

Embodiment 1

[0048] The preparation method of sodium glycerophosphate:

[0049] (1) Salt formation and esterification

[0050] Quantitative phosphoric acid and glycerol are put into the esterification reaction cylinder, then add sodium carbonate, the three are sodium carbonate 53g, phosphoric acid 98g, glycerol 184g by weight;

[0051] Introduce steam; in the reaction cylinder, phosphoric acid and sodium carbonate undergo a salt reaction to generate sodium dihydrogen phosphate, and then sodium dihydrogen phosphate and glycerin undergo an esterification reaction to generate diglyceride sodium glycerophosphate; the reaction process controls the pH value to 4.6 and maintains the vapor pressure 0.4-0.5MPa, reaction temperature 135°C; after the reaction, add an appropriate amount of purified water to dilute it;

[0052] (2) Hydrolysis

[0053] After esterification, add 45ml of 30% sodium hydroxide solution; sodium glycerophosphate and sodium hydroxide undergo hydrolysis reaction to generate s...

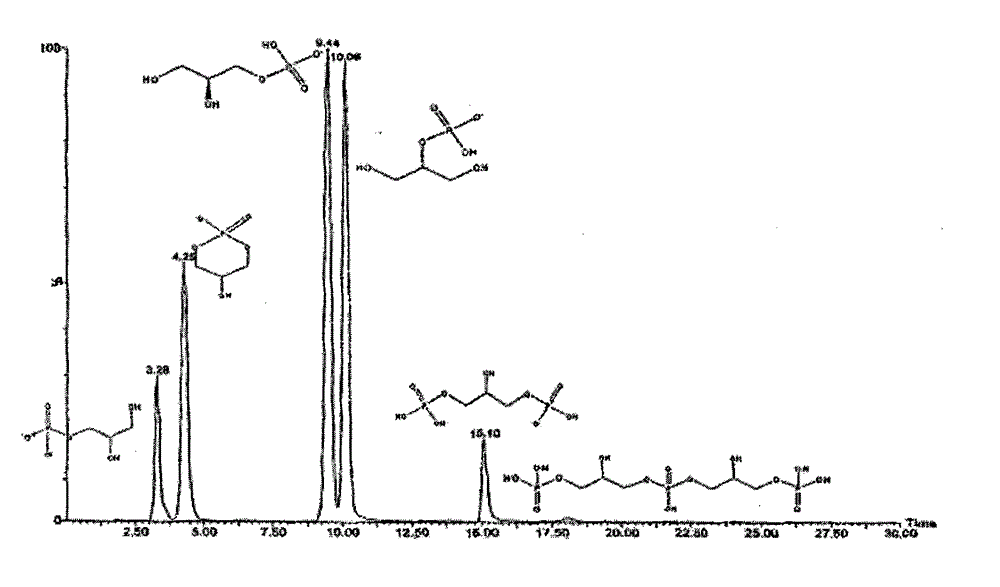

Embodiment 2

[0095] The preparation method of sodium glycerophosphate:

[0096] (1) Salt formation and esterification

[0097] Quantitative phosphoric acid and glycerol are put into the esterification reaction cylinder, then add sodium carbonate, the three are sodium carbonate 53g, phosphoric acid 98g, glycerol 184g by weight;

[0098] Steam is introduced; phosphoric acid and sodium carbonate undergo a salt reaction in the reaction cylinder to generate sodium dihydrogen phosphate, and then sodium dihydrogen phosphate and glycerin undergo an esterification reaction to generate diglyceride sodium glycerophosphate; the reaction process controls the pH value to 3.0-5.5, and maintains Vapor pressure 0.4-0.5MPa, reaction temperature 130°C; after the reaction, add an appropriate amount of purified water to dilute it;

[0099] (2) Hydrolysis

[0100] After esterification, add 40ml of 30% sodium hydroxide solution; sodium glycerophosphate and sodium hydroxide undergo hydrolysis reaction to genera...

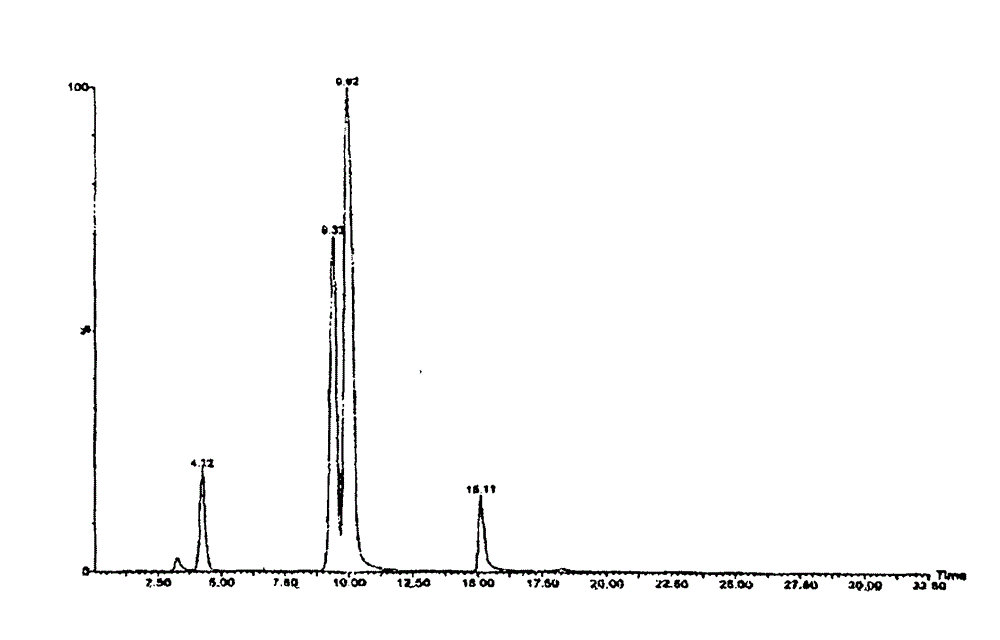

Embodiment 3

[0113] The preparation method of sodium glycerophosphate:

[0114] (1) Salt formation and esterification

[0115] Quantitative phosphoric acid and glycerin are put into the esterification reaction cylinder, then add sodium carbonate, the three are sodium carbonate 55g, phosphoric acid 100g, glycerol 165g by weight;

[0116] Introduce steam; in the reaction tank, phosphoric acid and sodium carbonate undergo a salt reaction to generate sodium dihydrogen phosphate, and then sodium dihydrogen phosphate and glycerin undergo an esterification reaction to generate diglyceride sodium glycerophosphate; the reaction process controls the pH value to 4.5 and maintains the vapor pressure 0.5MPa, reaction temperature 125°C; after the reaction, add an appropriate amount of purified water to dilute it;

[0117] (2) Hydrolysis

[0118] After esterification, add 37ml of 30% sodium hydroxide solution; sodium glycerophosphate and sodium hydroxide undergo a hydrolysis reaction to generate sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com