Blast furnace blower redundancy anti-surge control method

A control method and blower technology, applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as unstable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

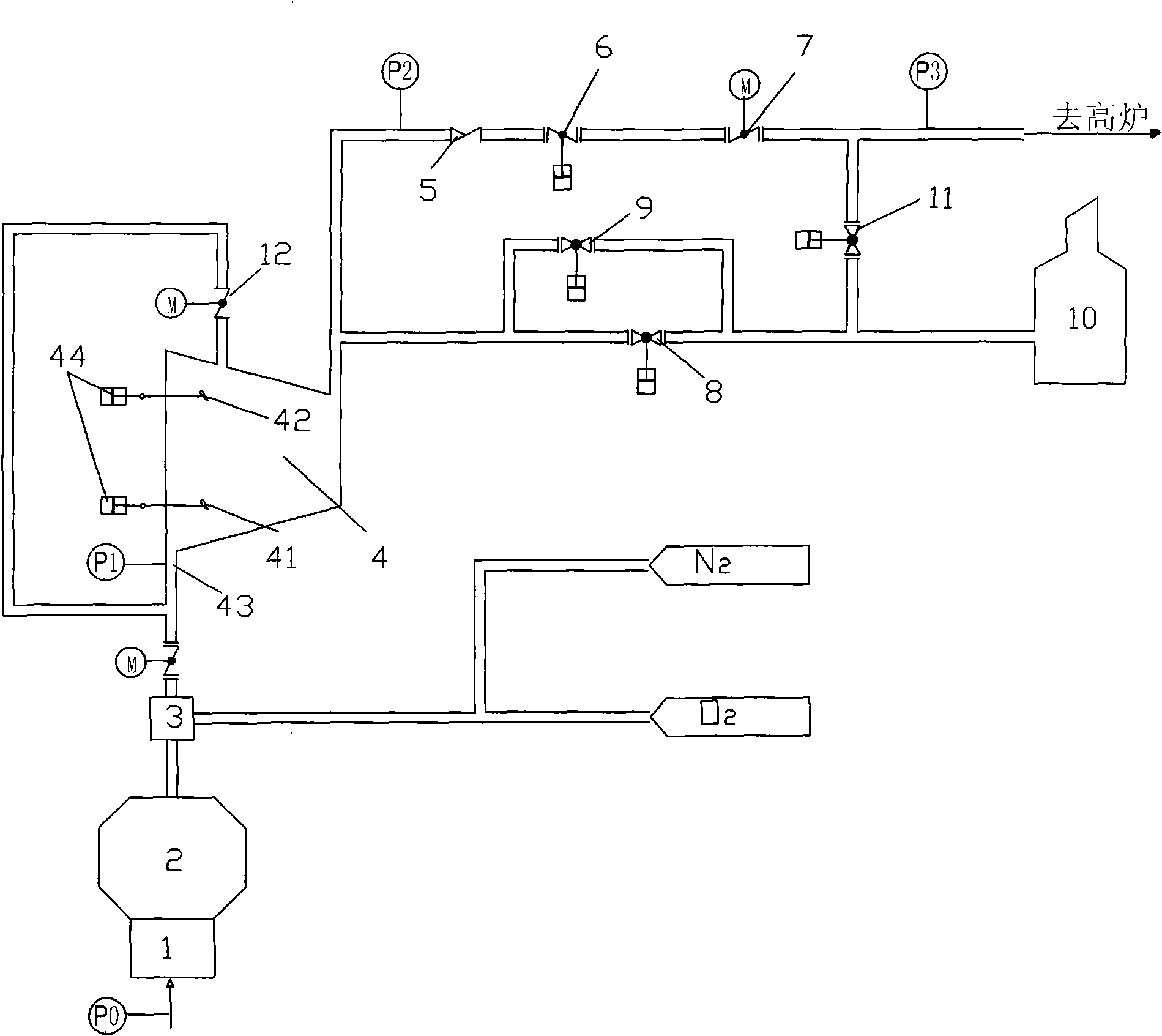

[0035] see Figure 1 ~ Figure 3, the blast furnace blower redundant anti-surge control method of the present invention, the atmosphere is sent into the dehumidifier 2 through the air filter 1, the humidity in the air is reduced, and the oxygen (oxygen-enriched) required by the blast furnace enters the blower 4 through the oxygen mixer 3, To improve the combustion efficiency of the hot blast furnace of the blast furnace, the air is pressurized in the blower 4 and then sent to the blast furnace through the check valve 5, the anti-blocking valve 6 and the discharge valve 7. A connecting pipeline with a rapid decompression valve 11 and a corresponding rapid decompression valve regulator are connected between the pipelines connecting the outlet main pipe of the blower fan 4 to the blast furnace and the exhaust muffler 10 respectively;

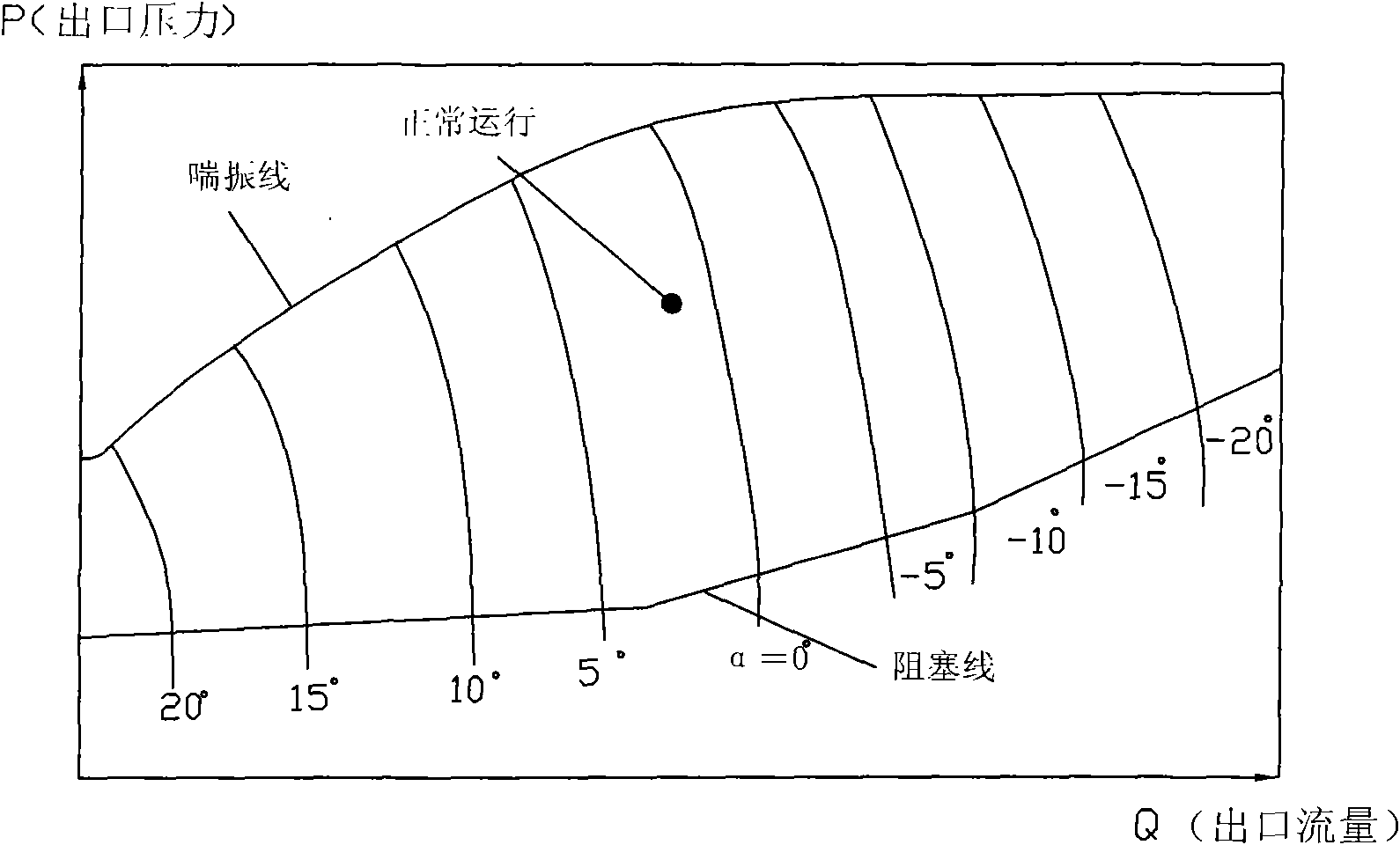

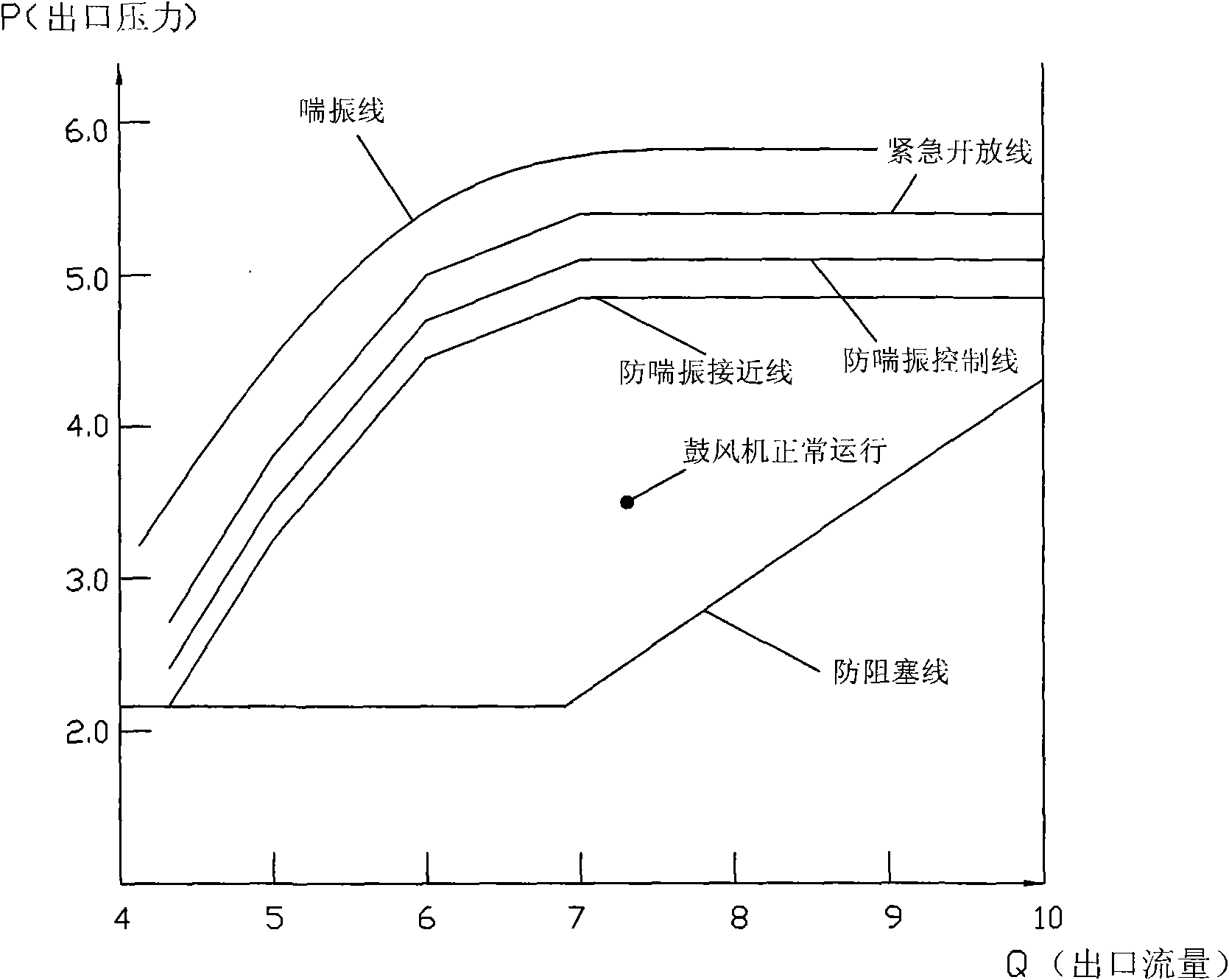

[0036] see Figure 4 , Image 6 , during normal operation, the setting value SV1 of the rapid decompression valve regulator 12 is higher than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com