Spline pair of hollow shaft fork

The technology of spline pair and hollow shaft is applied in the field of hollow shaft fork spline pair, which can solve the problems of high processing cost and material cost, energy consumption and chips, etc., and achieve the effect of weight reduction and excellent work performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

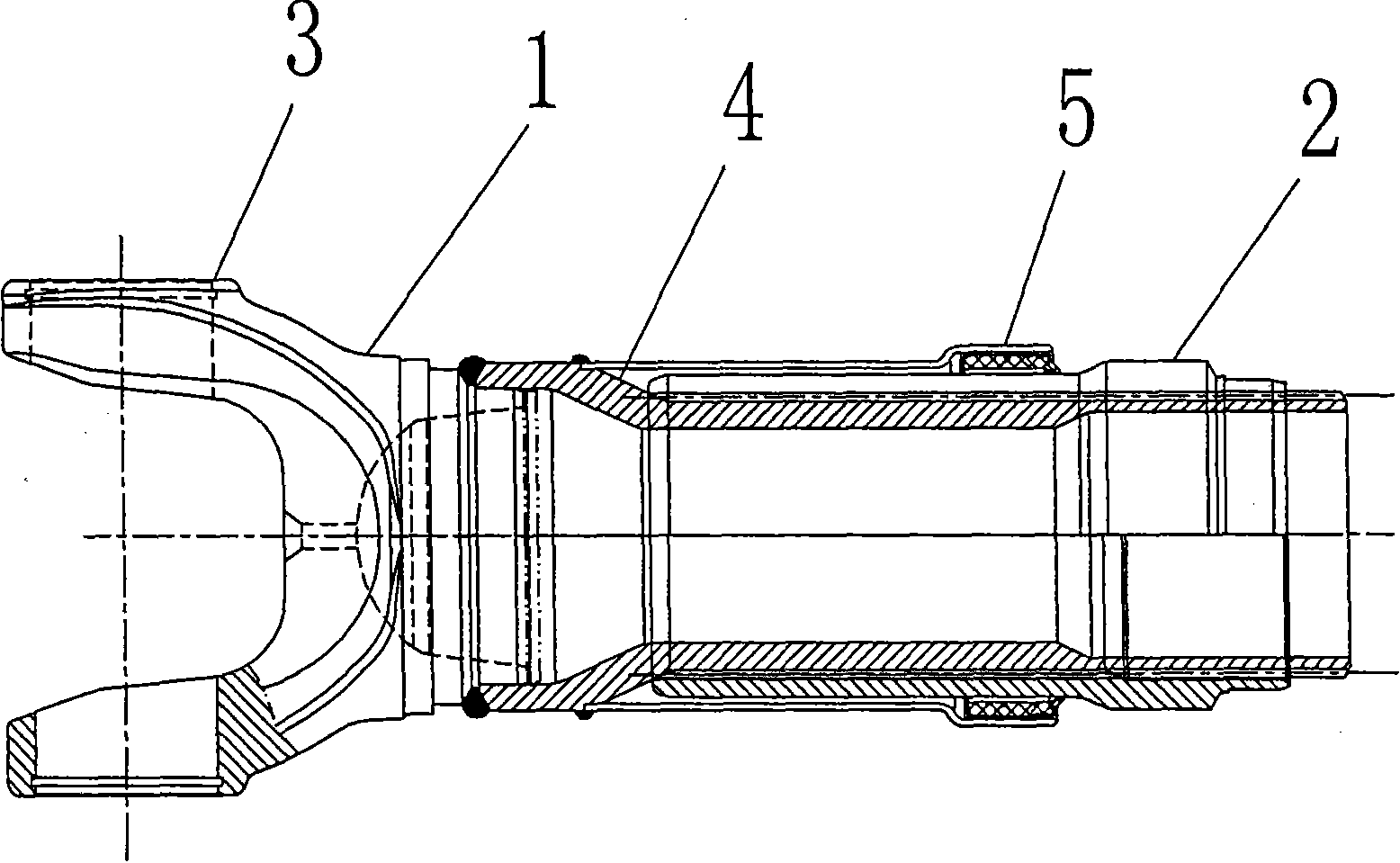

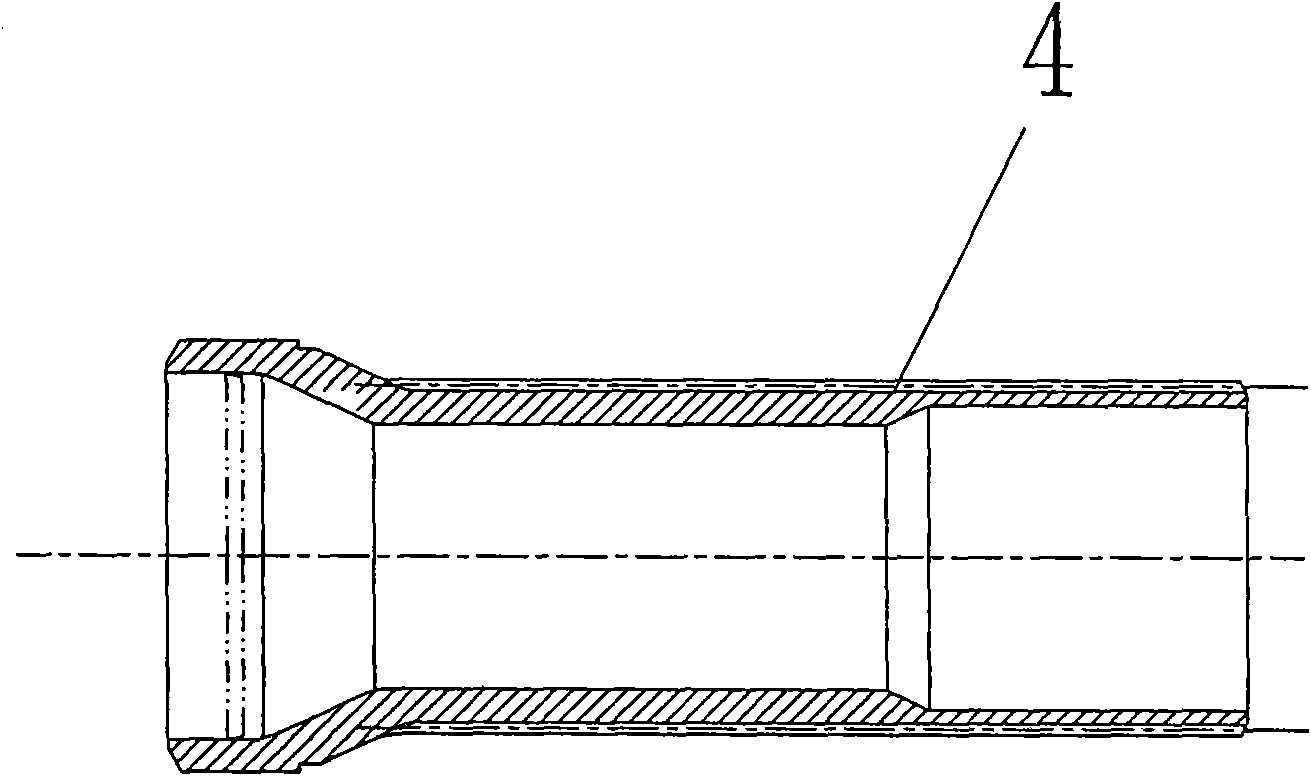

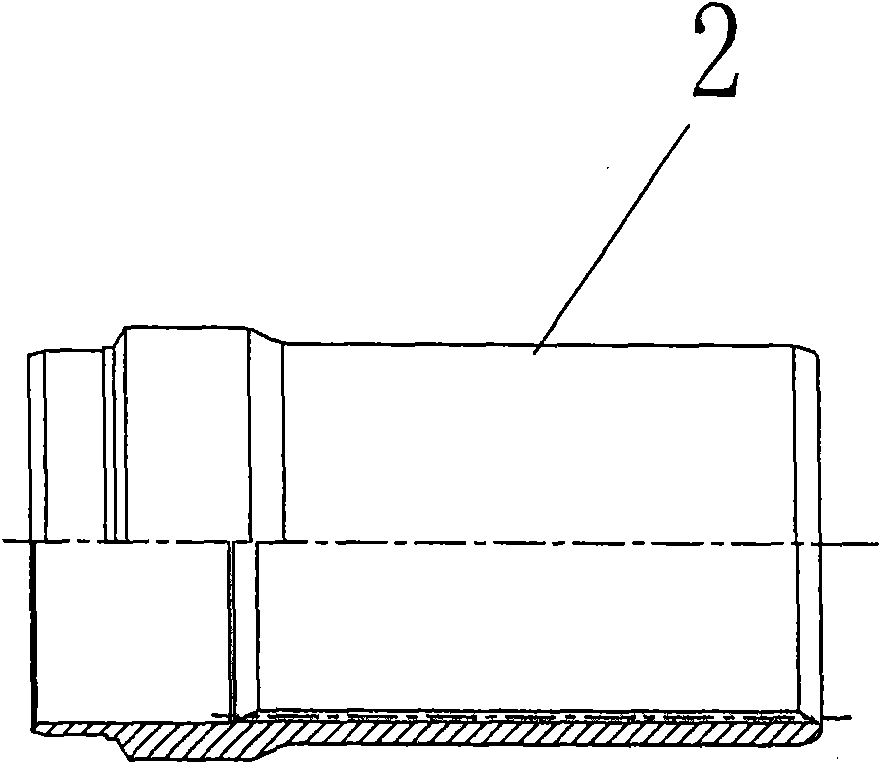

[0014] As shown in the figure, this hollow shaft fork spline pair mainly includes a spline shaft fork 1 and an inner spline spline sleeve 2. The spline shaft fork 1 is composed of a welding fork 3 and an outer spline spline sleeve 4. The fork 3 and the outer spline spline sleeve 4 are welded into an integral structure. The inner spline spline sleeve 2 is set on the outside of the outer spline spline sleeve 4, and the inner spline spline sleeve 2 and the outer spline sleeve 4 cooperate with each other. The outer spline spline sleeve 4 is a hollow structure. The inner spline spline sleeve 2 is covered with a sealing device 5, and the sealing device 5 and the spline shaft fork 1 are welded and fixed to isolate external impurities and dust.

[0015] The present invention adopts welding fork 3 and outer spline spline sleeve 4 to be welded together, and welding f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com