Performance testing device of static-pressure air bearing

A floating bearing and performance technology, which is applied in the field of performance testing of precision equipment, can solve the problems of bearing performance analysis, structural parameter experimental verification, difficult to obtain accurately, and gas pressure distribution in the bearing that cannot be directly detected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

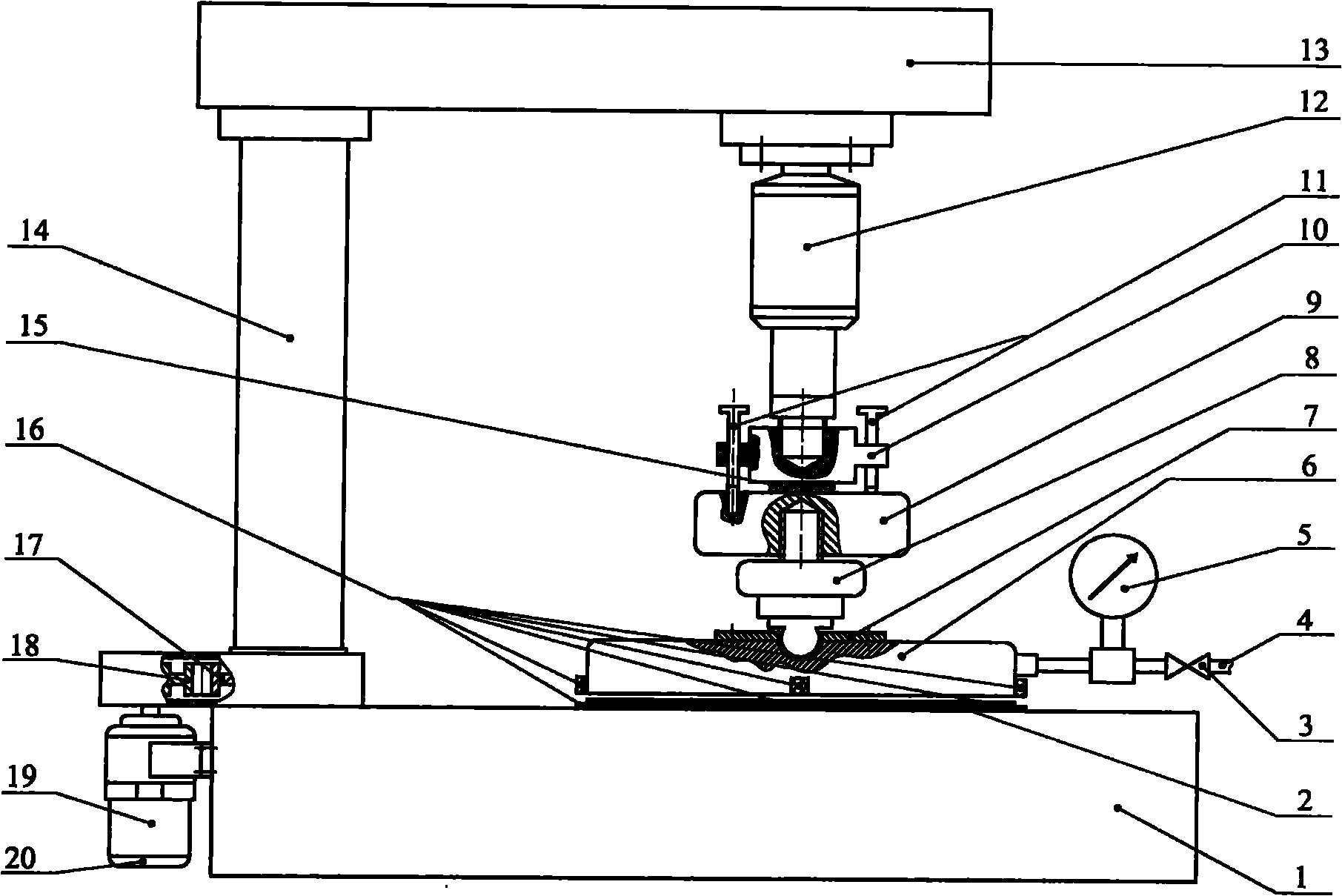

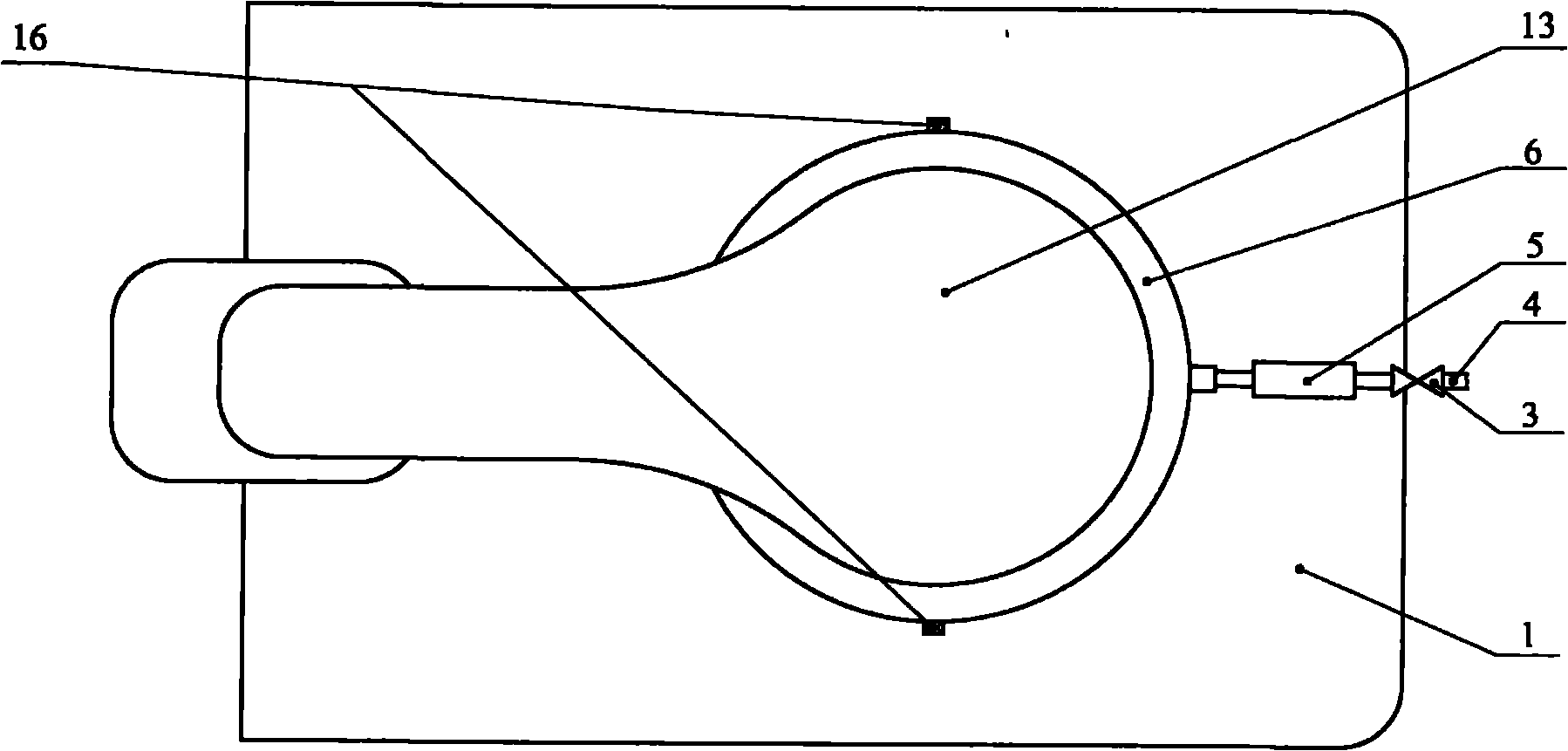

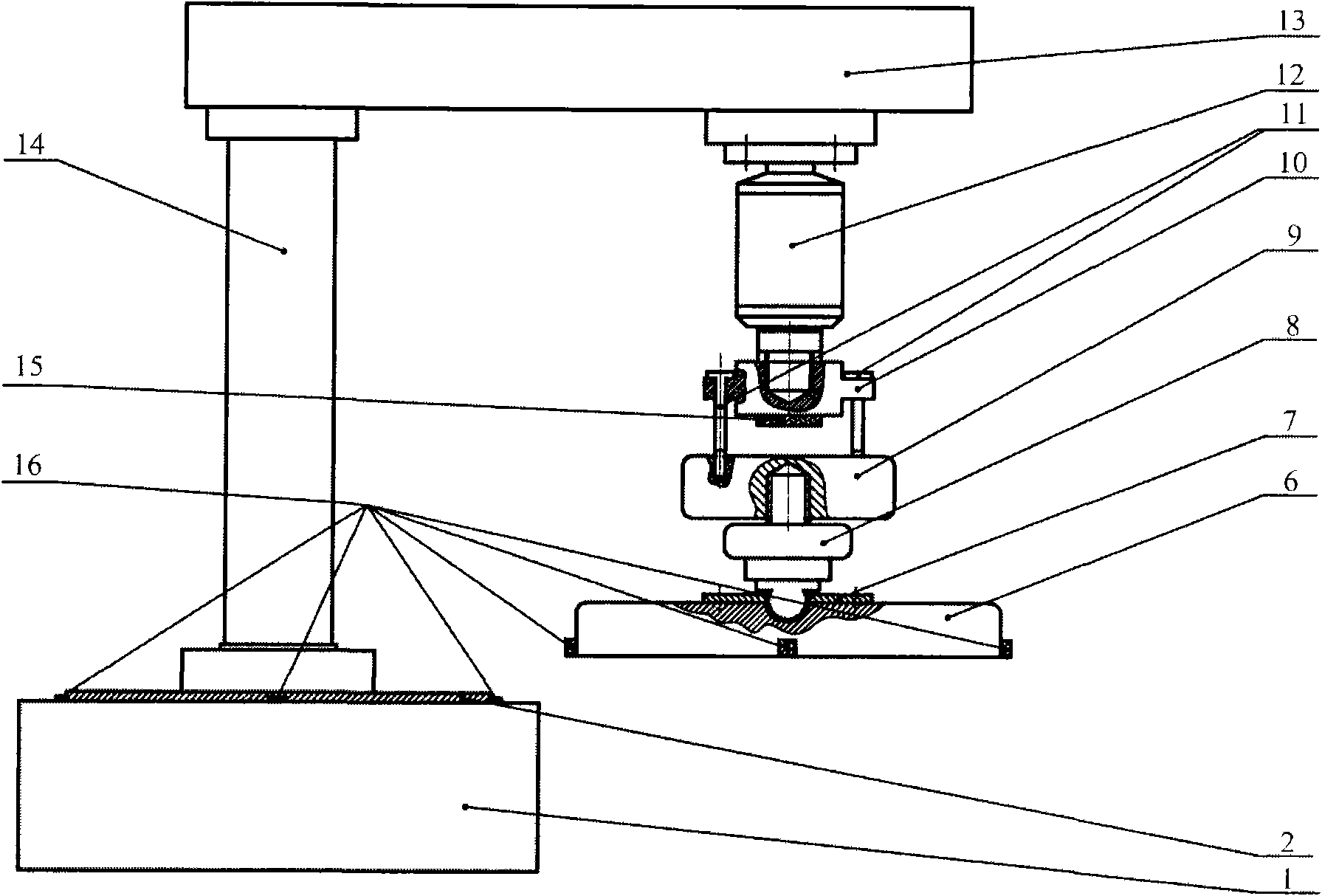

[0017] The thin film pressure sensor 2 of the present invention is fixed on the base 1, the pressure regulating valve 3 and the gas pressure gauge 5 are installed on the intake pipe 4, and the static pressure air bearing 6 to be measured passes through the pressure plate 7, the bearing fixing part 8 and the bearing connecting part 9. The linear driver connector 10 and the limit bolt 11 are installed on the linear driver 12, the linear driver 12 is fixed to the rack 13, the rack 13 is fixed on the bracket 14, the force sensor 15 is fixed on the linear driver connector 10, and the displacement The sensor 16 is fixed on the tested static pressure air bearing 6 and the base 1, the drive motor 19 is fixed on the base 1, and the rotary encoder 20 fixes the lower part of the drive motor 19 for measuring the rotation angle of the drive motor 19 rotor , the driving motor 19 drives the bracket 14 to rotate through the driving gear 18 and the driven gear 17 .

[0018] When detecting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com