Workpiece flaw identification method based on compound characteristics in magnaflux powder inspection environment

A technology of magnetic particle flaw detection and compound features, which is applied in character and pattern recognition, material magnetic variables, computer components, etc., can solve problems such as limited applicability, single flaw features, and lack of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

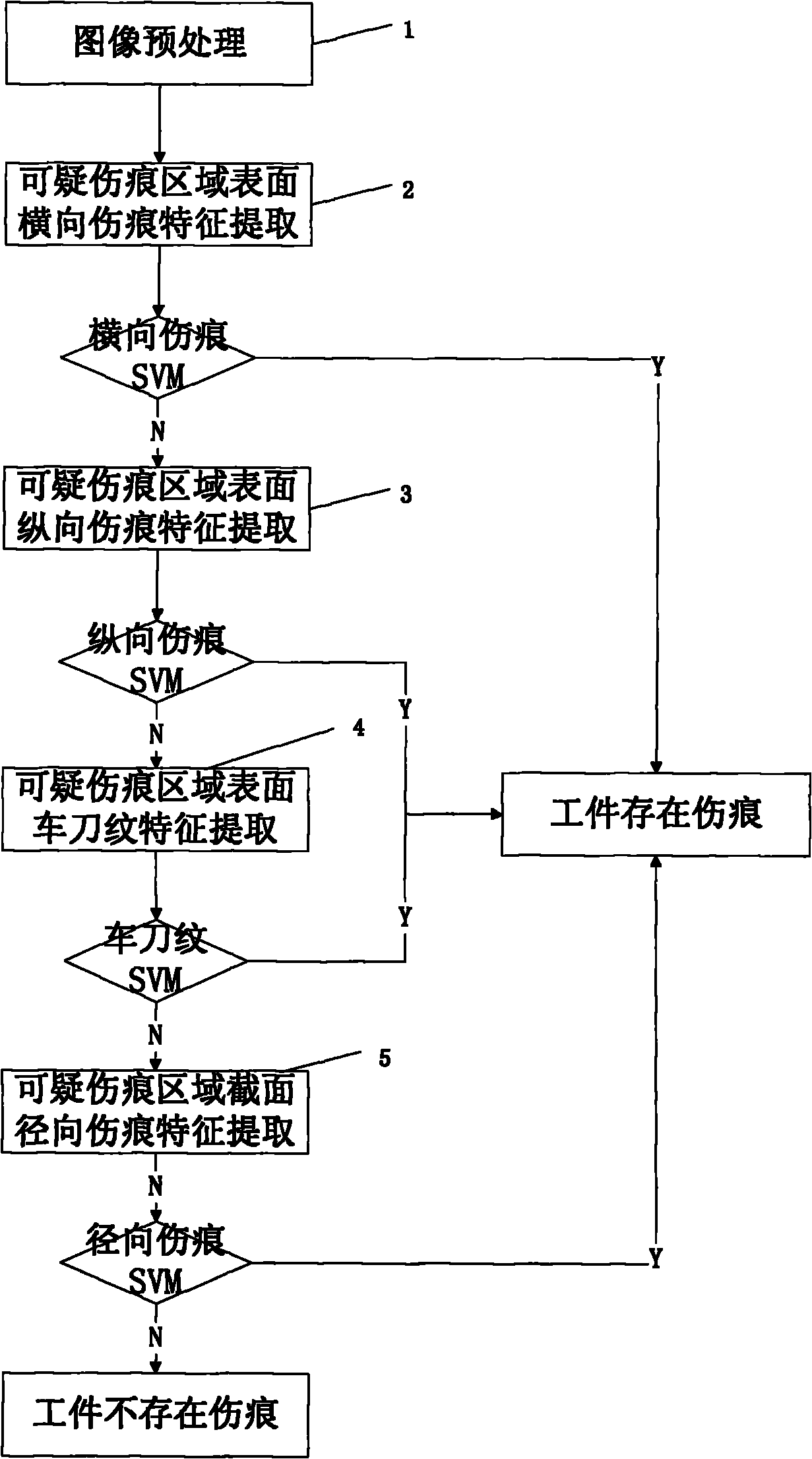

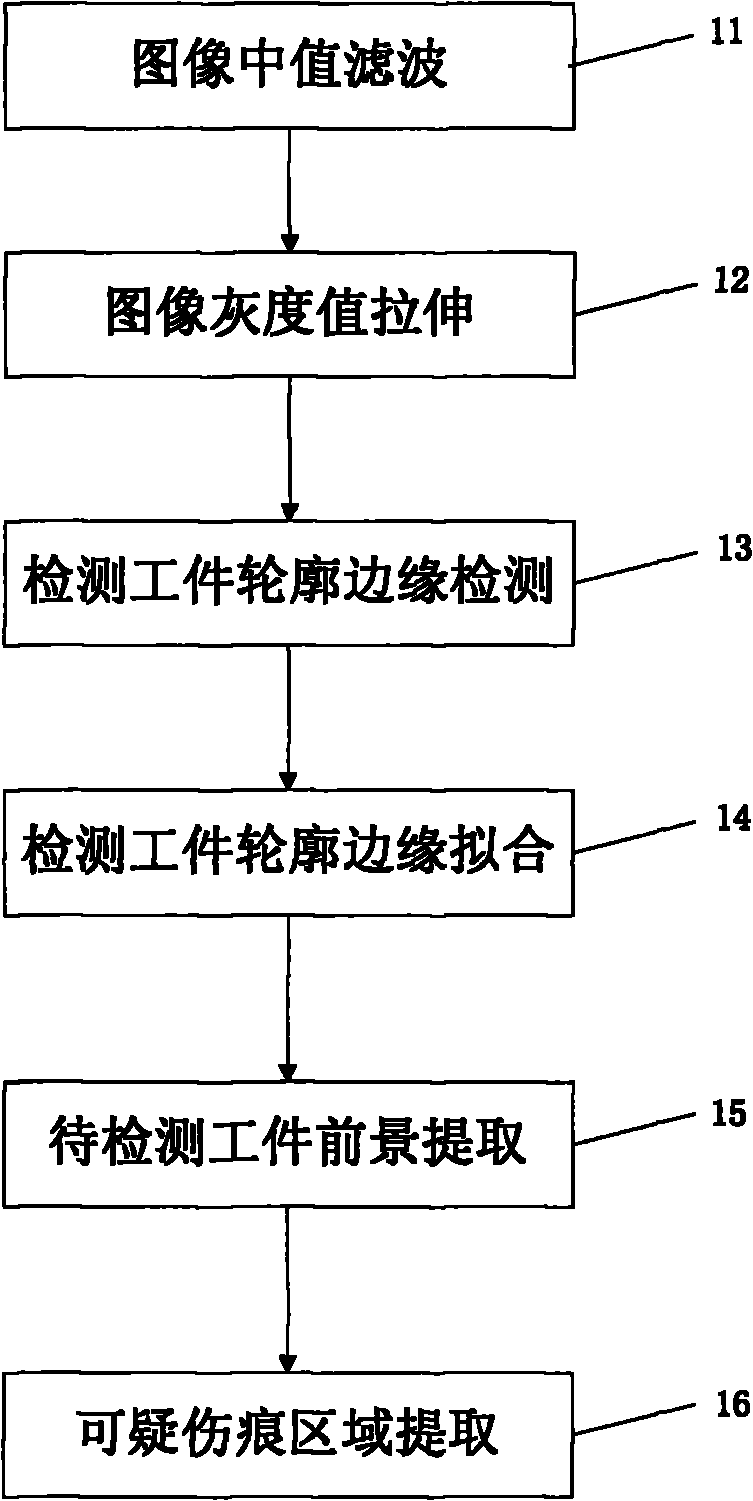

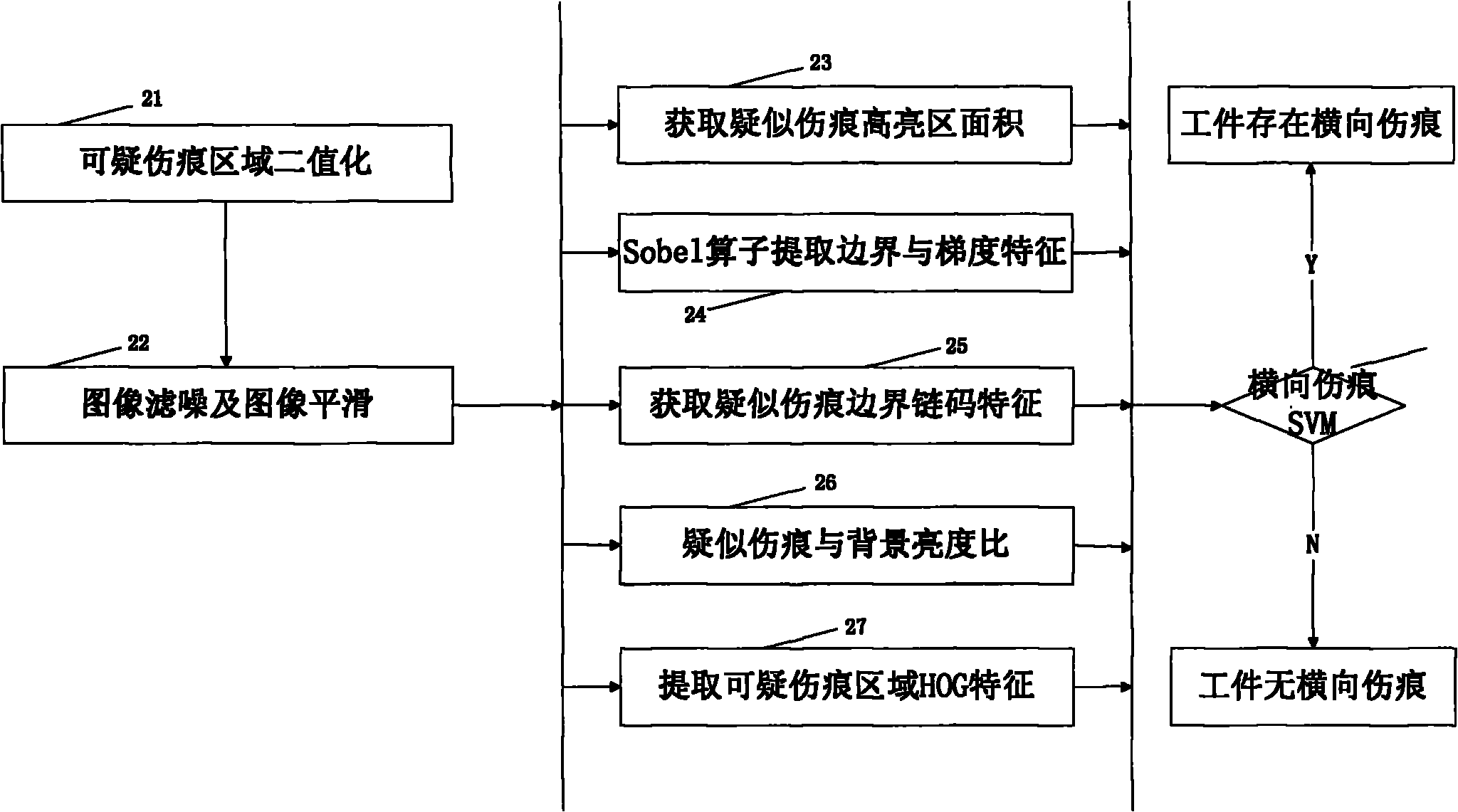

[0105] Embodiment 1: as figure 1 As shown in the figure, the flow chart of the automatic detection of flaws in the workpiece image under the magnetic particle inspection environment is described in the figure. This flow chart describes a method for identifying workpiece flaws based on composite features in a magnetic particle inspection environment, including the following steps:

[0106] Step 1: In the process of automatic flaw detection of the workpiece image, the image preprocessing of the workpiece image collected under the magnetic particle inspection environment is firstly carried out. The image preprocessing process includes image noise filtering, image enhancement and image segmentation. After the image segmentation is completed, the obtained Workpiece foreground area, image morphology operation is performed on the foreground area of the workpiece, and suspicious scar area is extracted. Since the magnetic particle inspection environment will be affected by a lot of ...

Embodiment 2

[0176] Embodiment 2: Embodiment 1 is aimed at the automatic detection method of flaws in images under the magnetic particle inspection environment. On the basis of Embodiment 1, the present invention also proposes an automatic detection method for flaws in the workpiece video under the magnetic particle inspection environment. For the automatic detection of flaws in the workpiece video, each video frame can be regarded as a workpiece image, but the biggest difference between the flaw detection in the video and the flaw detection in the image is that the same workpiece will form a continuous image sequence in the video, In this image sequence, there are both video frames judged to have scars and video frames judged to have no scars. Therefore, the recognition of scars is aimed at image sequences rather than single pictures. like Figure 8 As shown, the method for identifying workpiece flaws in the workpiece video under the magnetic particle inspection environment is described,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com