Magnetron for microwave oven

A technology for magnetrons and microwave ovens, applied in the field of magnetrons, can solve the problems of being unable to suppress and not considering the suppression of noise, and achieve the effect of suppressing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

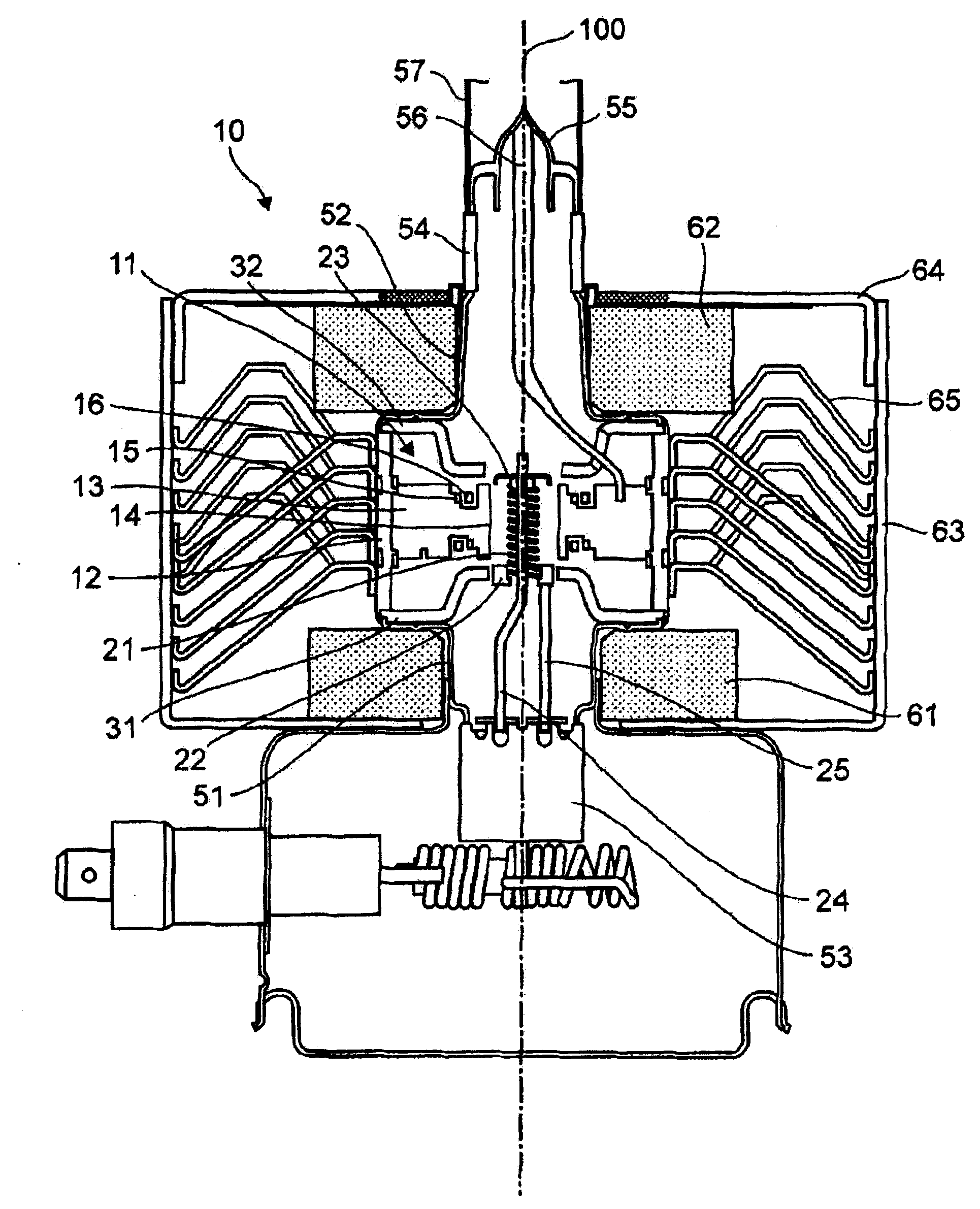

[0057] use Figure 1 to Figure 13 A magnetron according to an embodiment of the present invention will be described.

[0058] First, use figure 1 The schematic structure of the magnetron of this embodiment is demonstrated. figure 1 It is a schematic vertical cross-sectional view along the tube axis direction of the magnetron according to the embodiment of the present invention.

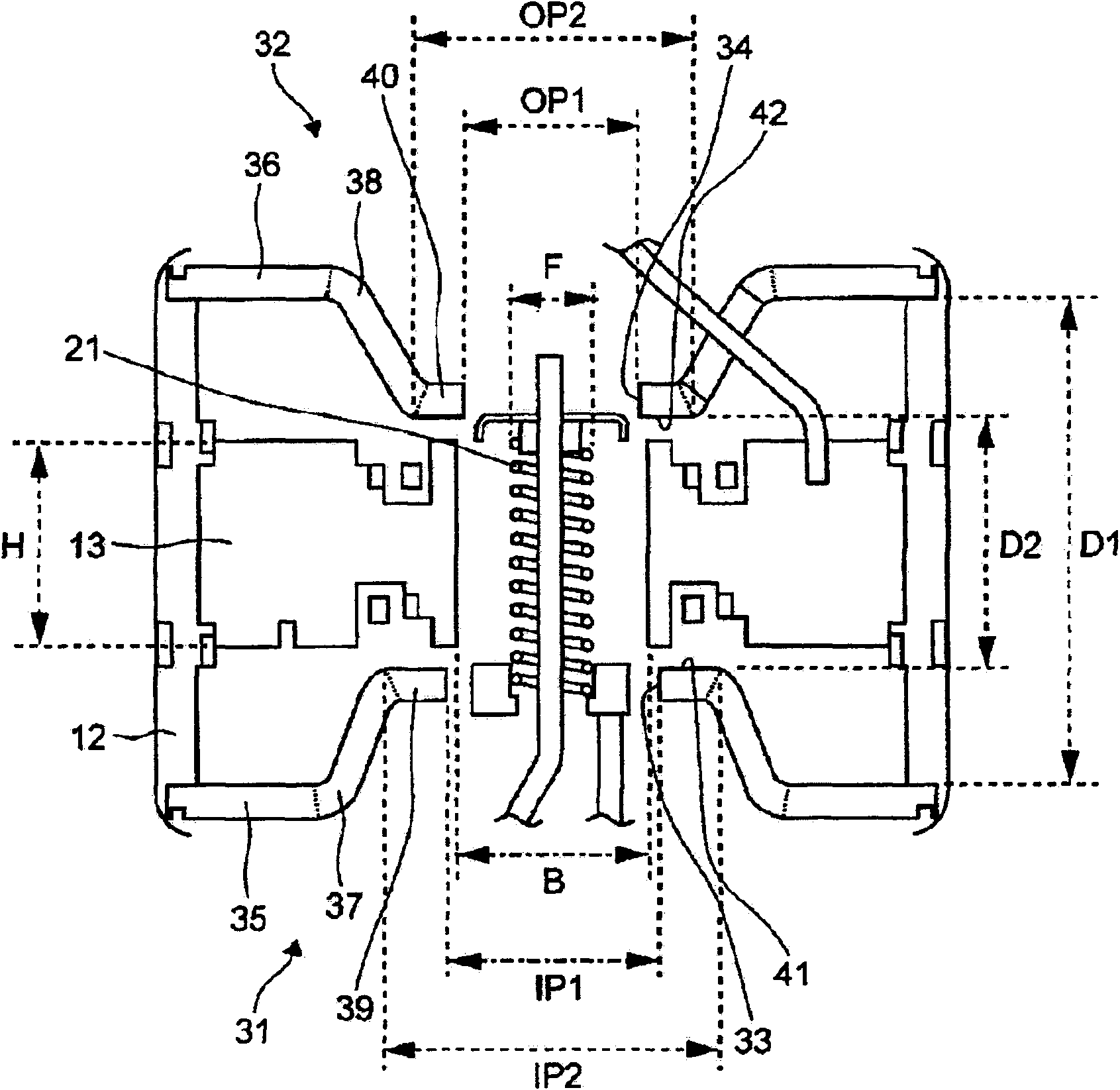

[0059] The anode part 11 has an anode cylinder 12 and ten fins 13 . The cylindrical anode cylinder 12 extends in the direction of the tube axis 100 which is the central axis of the magnetron 10 . One side of the ten plate-shaped fins 13 is joined to the inner wall of the anode cylinder 12 , and the other side is a free end. The free ends of the fins 13 are disposed on the same cylindrical surface extending along the tube axis 100, and this cylindrical surface is called the fin inscribed cylindrical surface 14. Ten fins 13 are inscribed on the cylindrical surface 14 from the fins. to the inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com