Manufacturing methods of inflatable deployable antenna reflecting surface based on shape memory polymer and reflecting surface film and skin thereof

A memory polymer, reflective surface technology, applied in the aerospace field, can solve the problem of inconvenient folding of the reflective surface of the expandable solid surface antenna, achieve convenient expansion and contraction processes, ensure rigidity and stability requirements, and high system reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

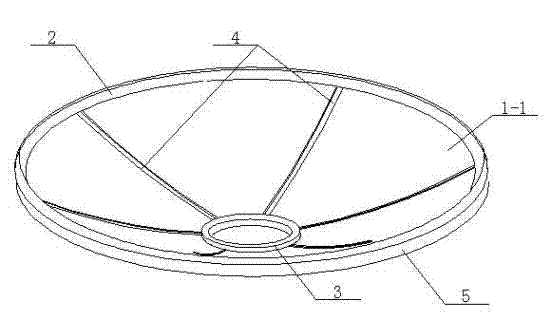

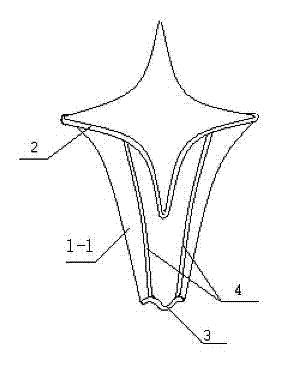

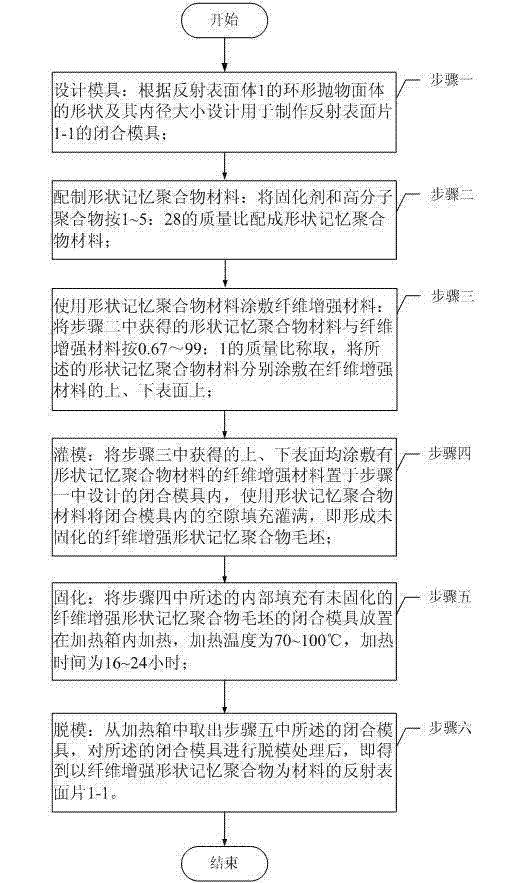

[0032] Specific implementation mode one: the following combination figure 1 , figure 2 , image 3 and Figure 4 This embodiment will be specifically described. An inflatable expandable antenna reflective surface based on shape memory polymer, which is composed of a reflective surface body 1, a first circumferential airbag 2, a second circumferential airbag 3, a radial airbag 4 and a skin 5, the reflector The surface body 1 is an annular paraboloid formed by splicing N pieces of the same reflective surface sheets 1-1, with a circular opening at the bottom. Each reflective surface sheet 1-1 is a fan-shaped curved surface lobe. The upper edge of the convex paraboloid of the surface body 1 is fixedly connected with the first annular airbag 2, and the lower edge of the convex paraboloid of the reflective surface body 1 is fixedly connected with the second annular airbag 3, and the first annular airbag 2 is connected with the second annular airbag 2. N radial airbags 4 arranged...

specific Embodiment approach 2

[0040] Specific implementation mode two: the following combination figure 1 , image 3 This embodiment will be specifically described. The difference between this embodiment and the first embodiment is that: the thickness of the reflective surface body 1 is 0.02-40mm; the outer radius of the reflective surface body 1 is 0.5-60m; the inner radius of the reflective surface body 1 is: 0.1-2m; the ratio of the focal length of the paraboloid of revolution of the reflective surface body 1 to the aperture of the paraboloid of revolution of the reflective surface body 1 is 0.025-2.5:1.

specific Embodiment approach 3

[0041] Specific embodiment three: the difference between this embodiment and specific embodiment one is: between the reflective surface sheet 1-1, the first circumferential airbag 2, the second circumferential airbag 3, the radial airbag 4 and the skin 5 Bonding, mechanical connection or a combination of bonding and mechanical connection are used.

[0042] According to the designed skeleton structure of the inflatable expandable antenna reflector, the closed first hoop airbag 2, the second hoop airbag 3 and N radial airbags 4 are placed in the compartments of N reflective surface sheets 1-1 in sequence Centered and fixed, the size and shape of the airbag is commensurate with the shape of the two-dimensional reflective surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com