Machine for unrolling and laterally aligning ribbons

A technology of machines and belts, applied in the field of conveyor-type cutting units, can solve the problems of troublesome structure duplication, inability to implement continuously and efficiently, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

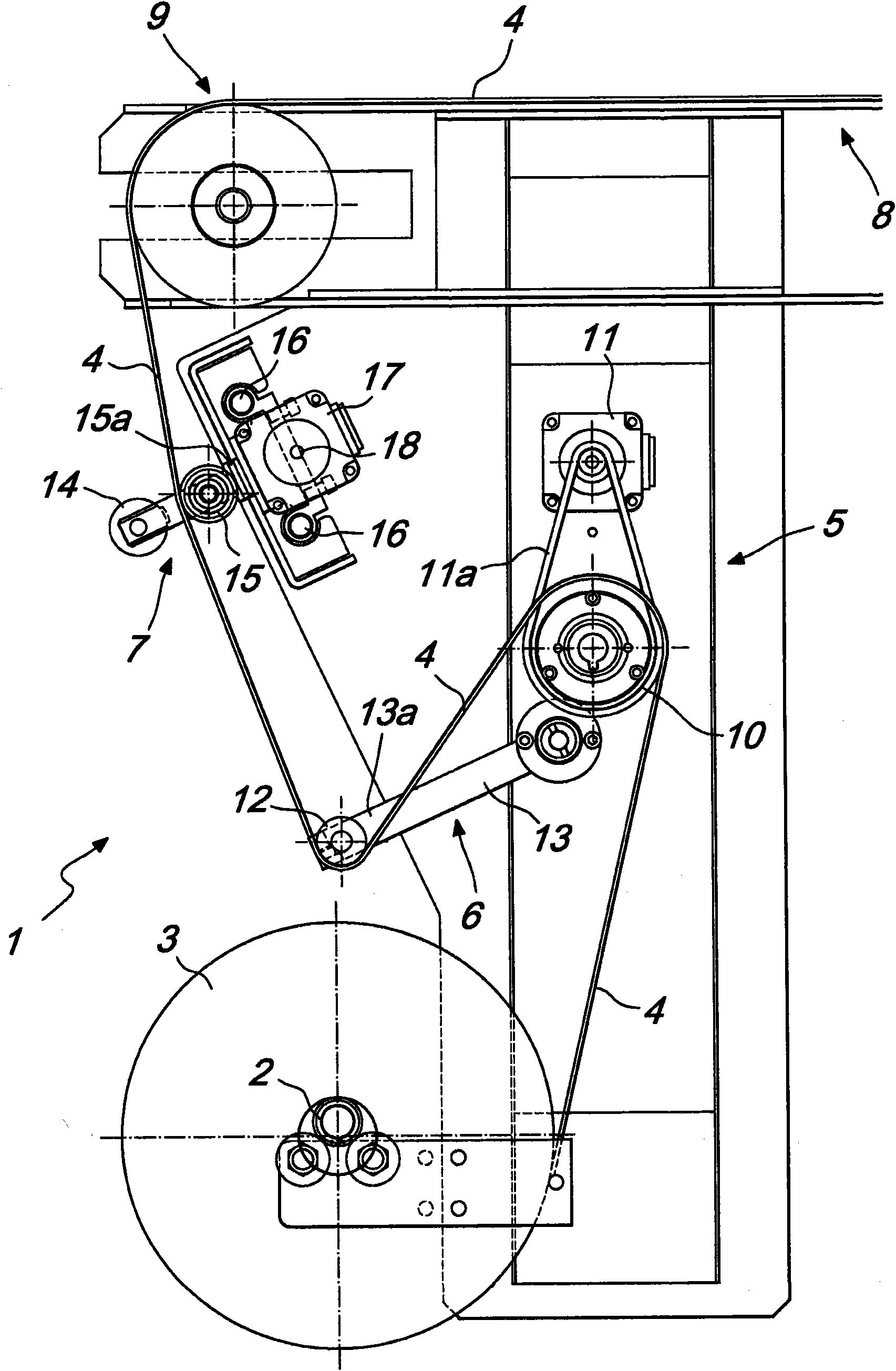

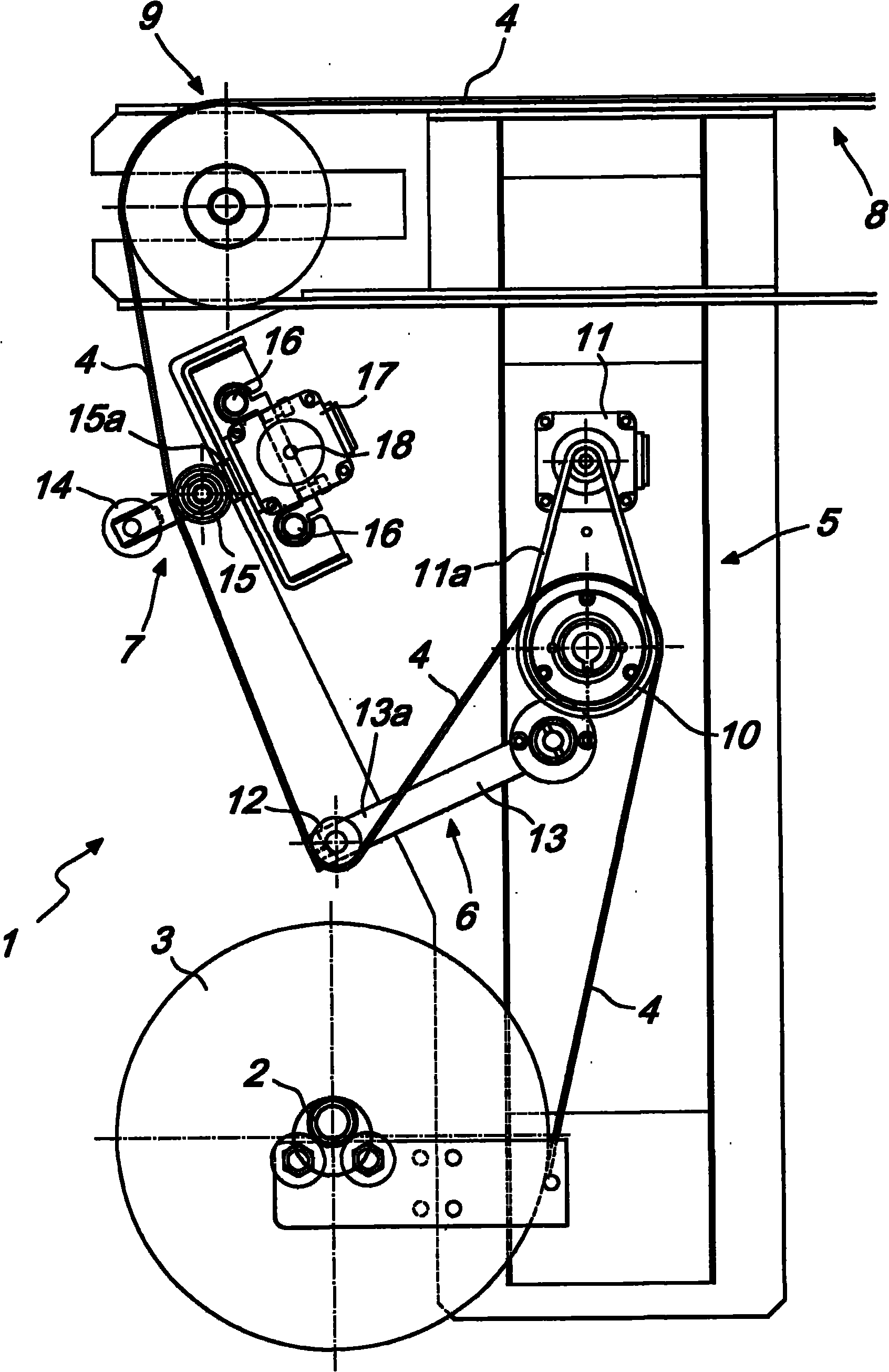

[0016] Referring to the accompanying drawings, a machine for unwinding and aligning fabric strips, synthetic materials, etc. 2 supports the roll 3 of tape 4, the motorized device 5 is used to unwind the roll 3 of tape 4, and the first assembly 6 is used to read the tension of the unwound tape 4 to adjust the motorized device 5 so as to eliminate the unwound Tension around the strap 4.

[0017] The machine 1 also comprises a side slide device 7 for laterally sliding the unwound tape 4 substantially without tension so as to align it on the table 8, and a second assembly 9, the second assembly 9 is used to read the lateral deviation of the tape 4 that has been unwound.

[0018] The motorized device 5 comprises an unwinding roller 10 , rotatable about its own axis parallel to the axis of the roll 3 , on which the unwound tape 4 is partially wound.

[0019] The motorized device 5 also comprises a first motor device 11 associated with the unwinding roller 10 by means of a belt dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com