Super hoisting device and telescopic-boom hoisting equipment with same

A technology of super-lifting device and hoisting equipment, which is applied in cranes and other directions, can solve the problems that the force cannot be reduced, the force of the boom luffing cylinder is large, etc.

Active Publication Date: 2010-10-13

SANY AUTOMOBILE HOISTING MACHINERY

View PDF7 Cites 43 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the general disadvantage of the superlift devices disclosed in the prior art is that although the side bending and deformation of the boom can be avoided as much as possible by this type of superlift device, the force of the boom luffing cylinder of the crane It is still very large, and its force cannot be reduced

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

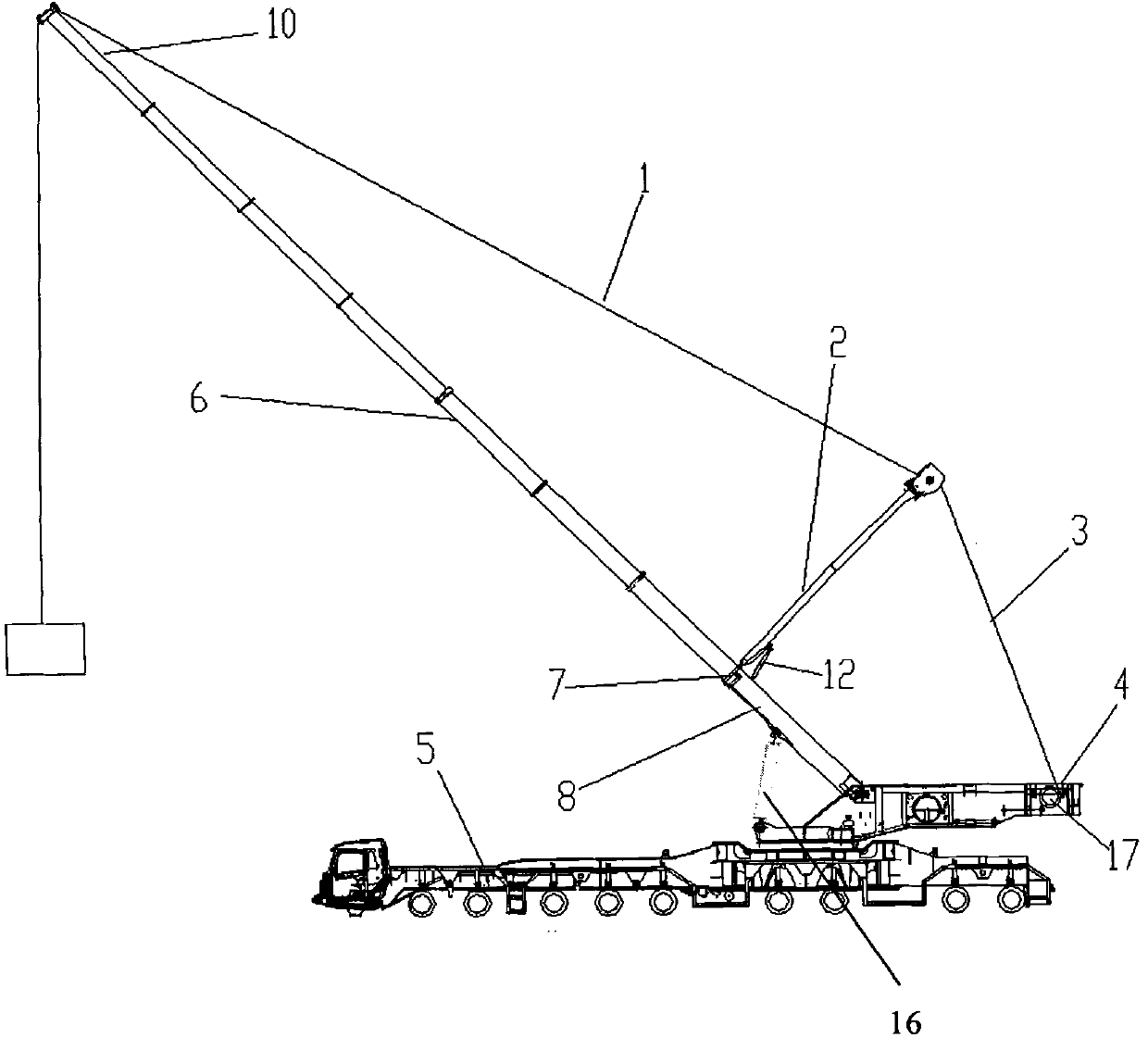

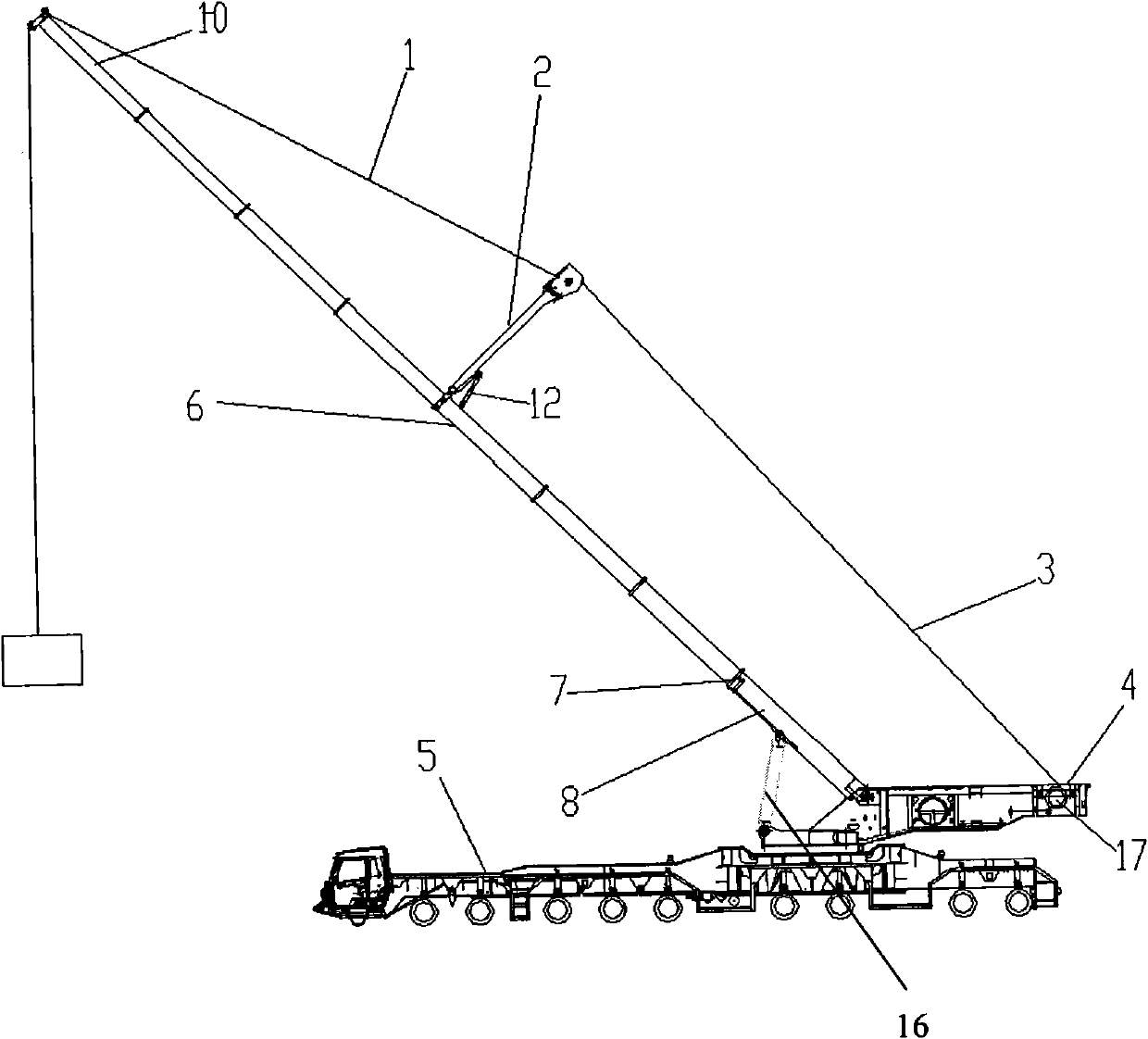

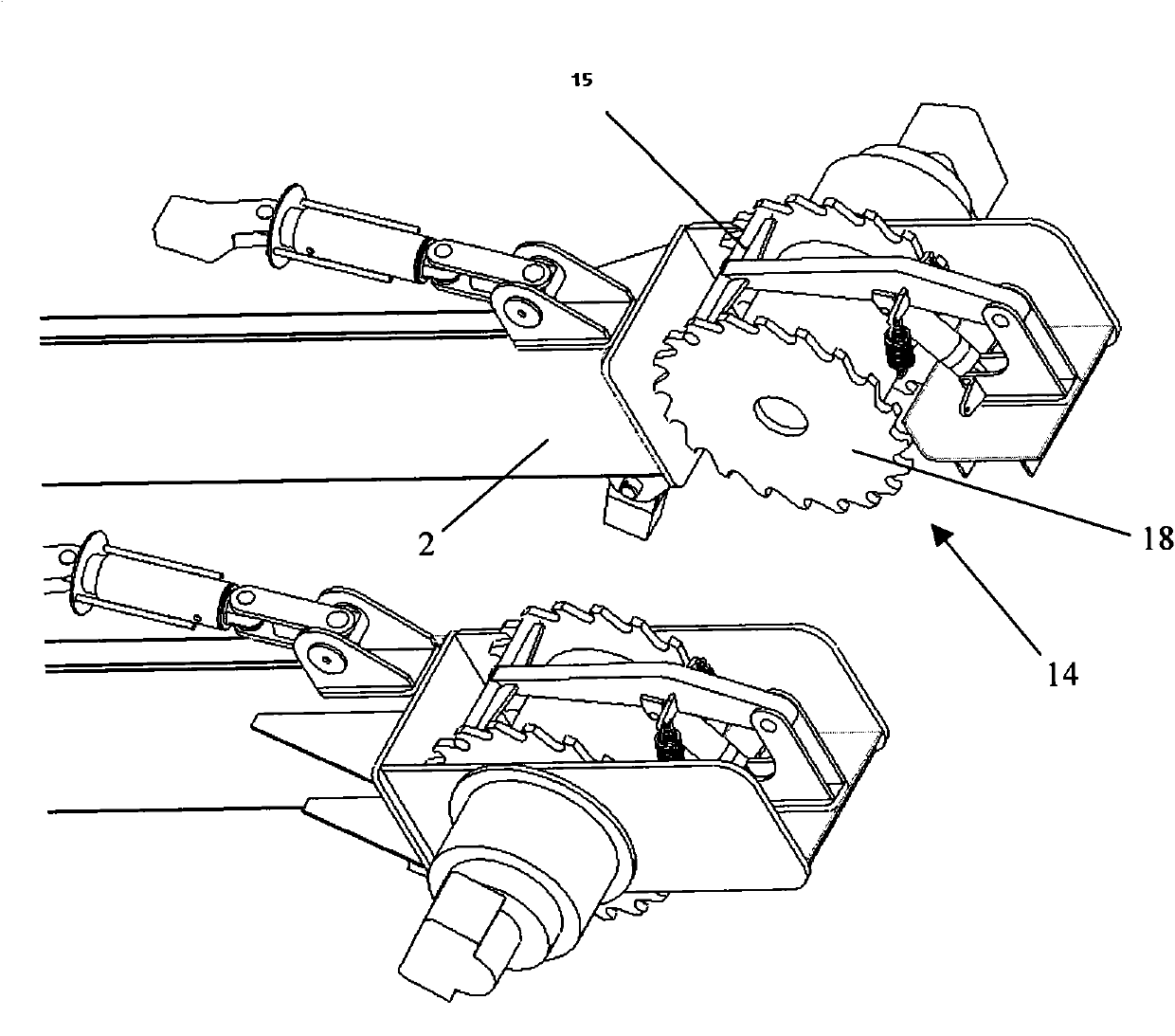

The invention relates to a super hoisting device for hoisting equipment, which comprises at least one super hoisting bracket (2), a first tensioning mechanism (1) and a second tensioning mechanism (3). The fixed end of the super hoisting bracket (2) is articulated with a hoisting boom (6) of the hoisting equipment; one end of the first tensioning mechanism (1) is connected to the movable end of the super hoisting bracket (2) and the other end is fixed to the head end of the hoisting boom (6); one end of the second tensioning mechanism is connected to the movable end of the super hoisting bracket (2) and the other end is connected to a turntable (4) of the hoisting equipment. In addition, the invention also relates to telescopic-boom hoisting equipment provided with the super hoisting device.

Description

technical field The invention relates to a super-lifting device for a lifting device, and a telescopic arm lifting device with the super-lifting device. Background technique Due to the large lifting capacity and long boom length of large-tonnage cranes, the cross-section of the boom is required to be large, and the weight of the boom also increases accordingly. The increase in self-weight affects the design of other components and the stability of the whole machine. At the same time, due to the length of the arm and the limitation of the height and width of the boom section, the slenderness ratio of the boom increases, and the stiffness becomes poor when hoisting, resulting in large side bending and poor stability of the boom itself. . In addition, the force on the luffing cylinder of a large-tonnage crane increases, and the diameter of the luffing cylinder also becomes larger, which affects the overall design and layout of the whole machine. Therefore, large-tonnage crane...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B66C23/72B66C23/82B66C23/687B66C23/36

CPCB66C23/826B66C23/36

Inventor 叶芳刘木南

Owner SANY AUTOMOBILE HOISTING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com