Power-on circuit for washing machine and power-on method thereof

A washing machine and circuit technology, applied in the field of washing machines, can solve problems such as limitations, and achieve the effects of simple structure, convenient use, and avoiding damage to keys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

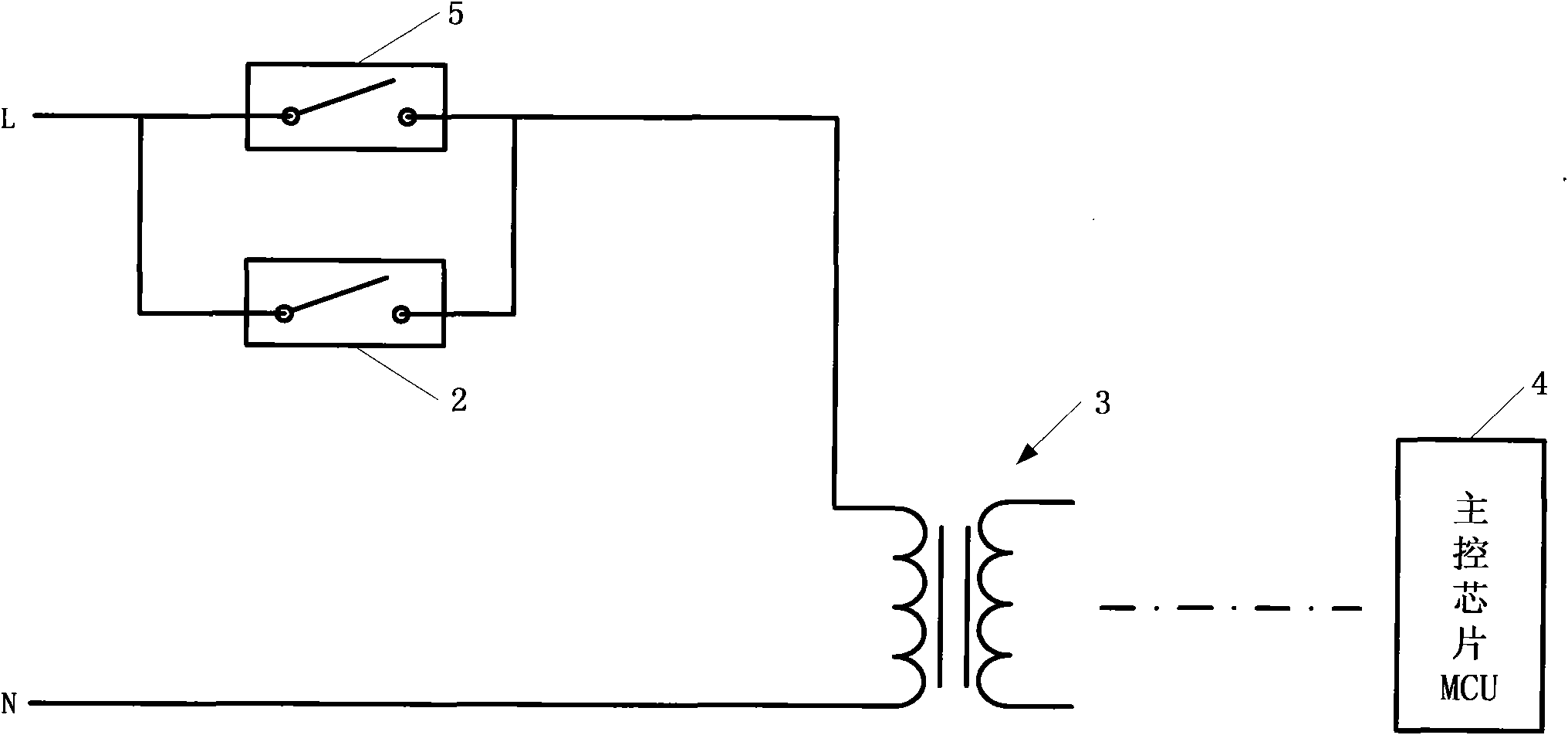

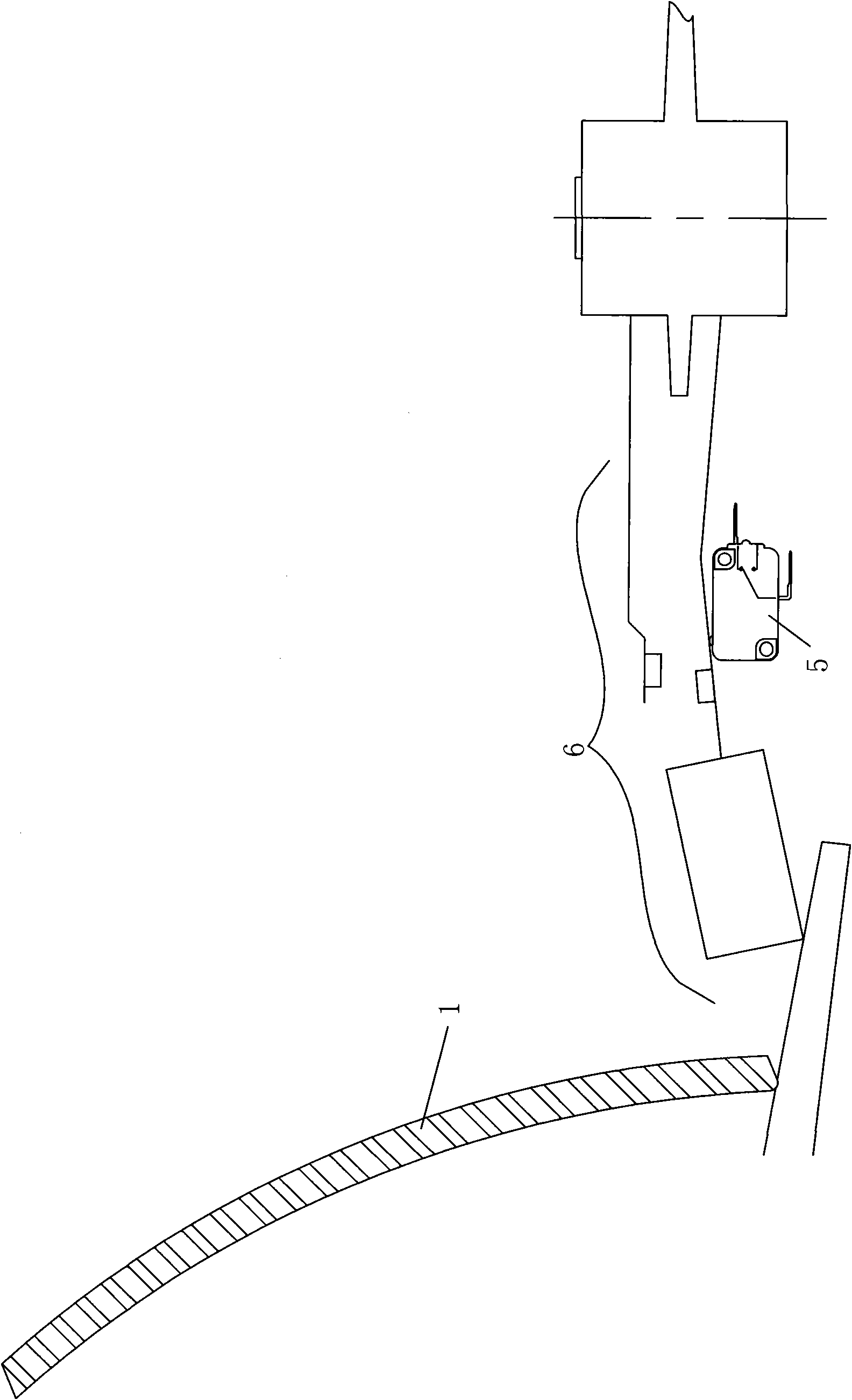

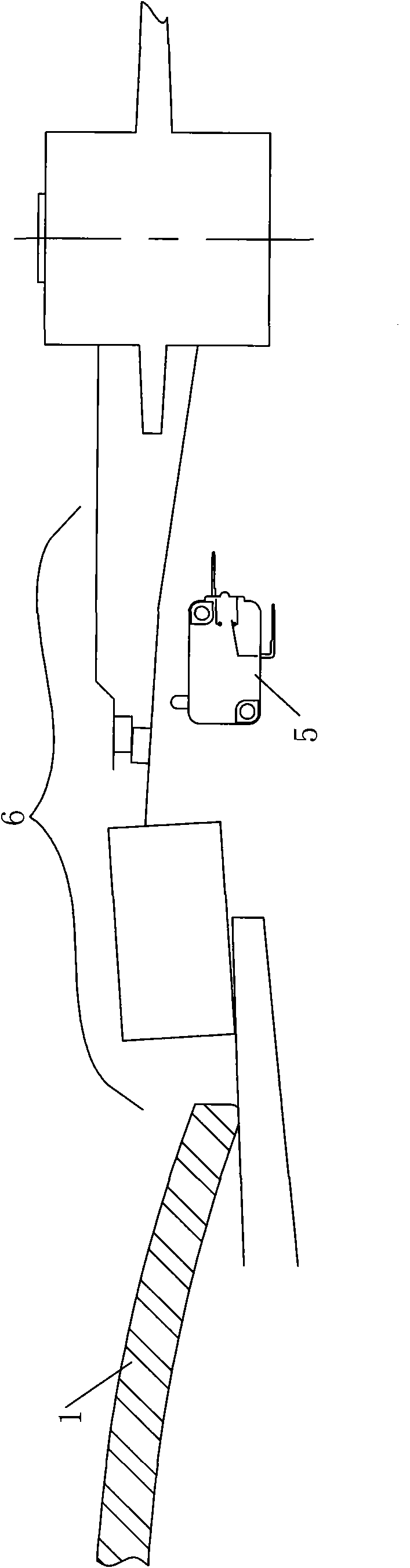

[0015] A power-on circuit for a washing machine, comprising a door cover 1, which is hinged to the washing machine body, and a control panel operable by the user, with touch buttons arranged on the control panel, and the washing machine body being in contact with the door cover 1 A linkage switch is set at the position of the door lock or in the keyhole of the door lock, and the linkage switch is connected in parallel with the main control relay 2 and connected with the main control chip MCU 4 through the transformer 3 . For the pulsator washing machine, the linkage switch includes a safety switch assembly 6 arranged under the door cover 1 and in contact with the lower end surface of the door cover 1, and a safety switch assembly 6 arranged under the safety switch assembly 6 and within the stroke of the safety switch assembly 6. The micro switch 5 inside, the safety switch component 6 is linked with the micro switch 5, the micro switch 5 is connected in parallel with the main c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com