Inertial navigation level measurement method applied to airplane general assembly

A level measurement and general assembly technology, applied in the field of inertial navigation level measurement applied to aircraft general assembly, can solve the problems of poor reliability of measurement data, inhibition of measurement accuracy and measurement efficiency, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

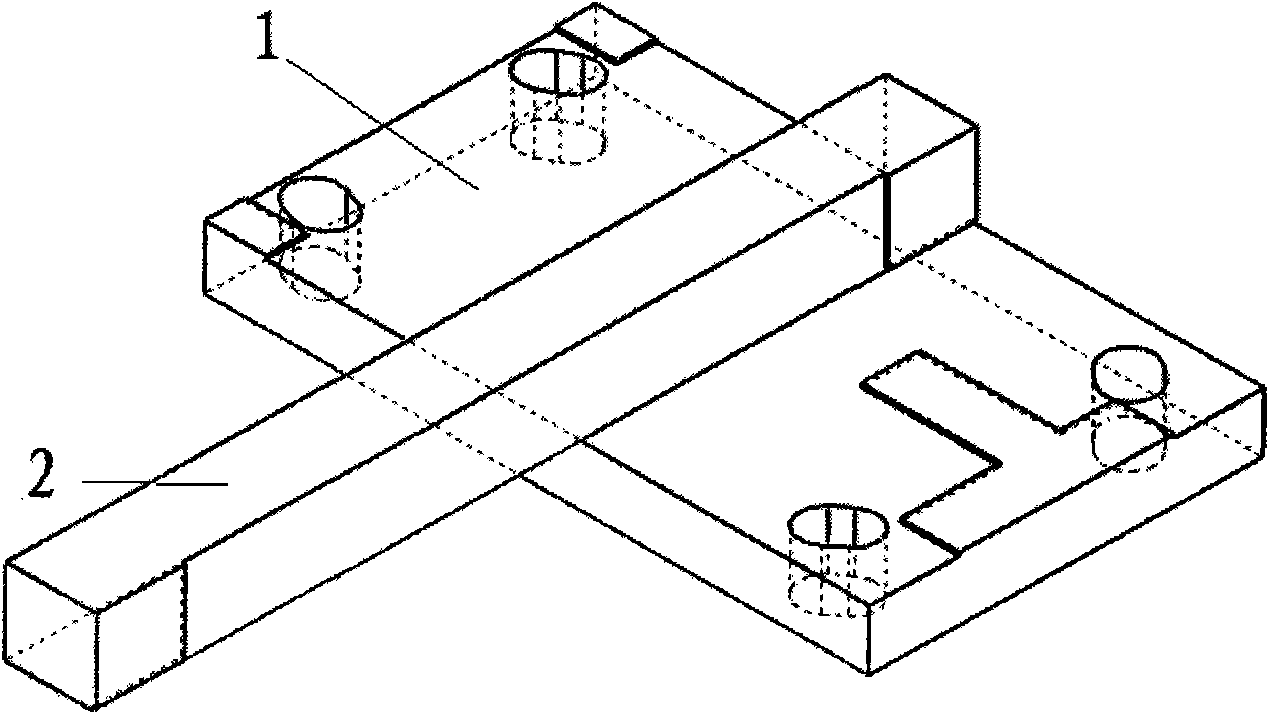

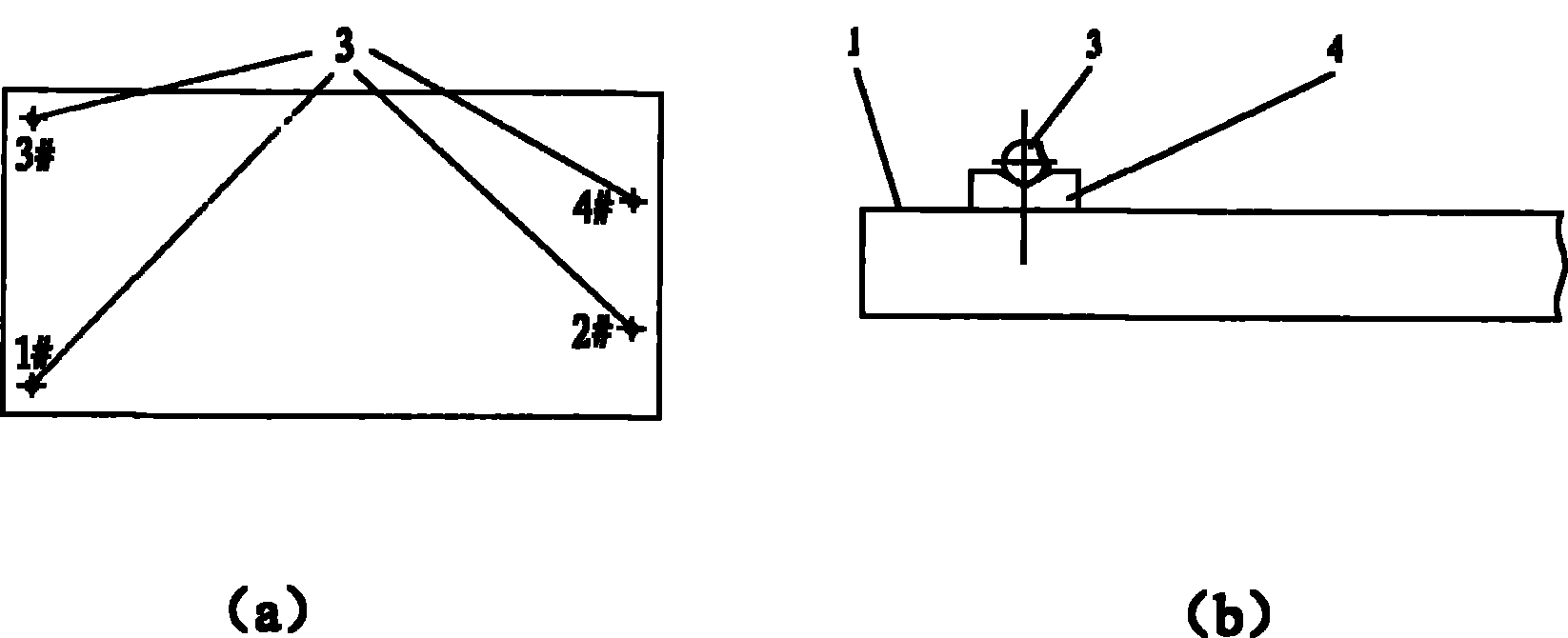

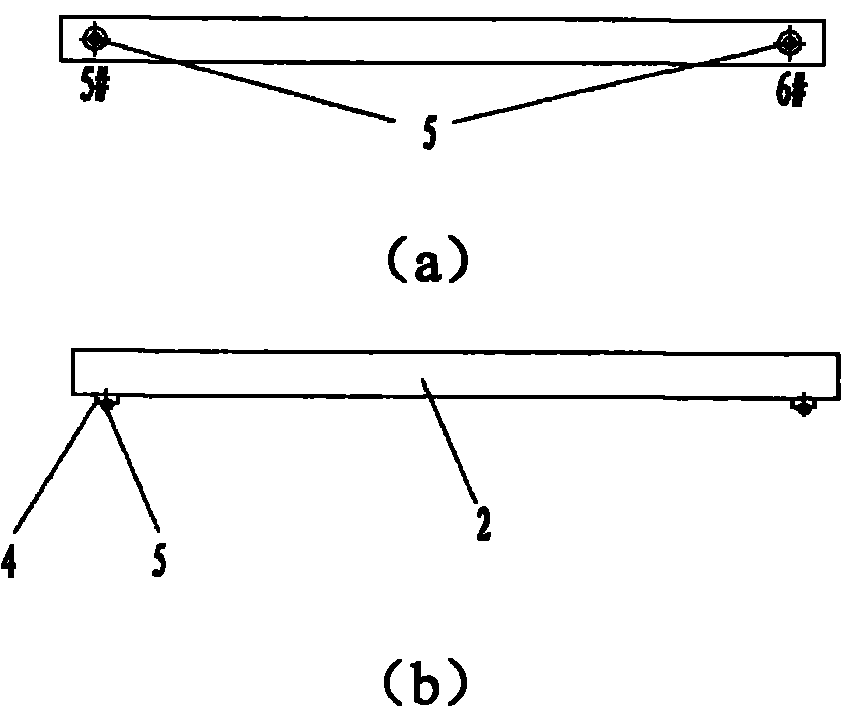

[0064] 1) Level the aircraft, that is, adjust the horizontal and longitudinal directions of the aircraft. The method is: arrange two measuring points symmetrically on the left and right wings of the aircraft. Two measurement points are arranged in the direction of the aircraft fuselage, and the height difference between the two points is within 0.5mm to achieve longitudinal leveling. Secondly, the measurement coordinate system of the laser tracker is the same as the assembly coordinate system of the aircraft general assembly station. Here, the laser The measurement coordinate system of the tracker refers to the spatial coordinate system automatically established by default after the laser tracker is turned on, while the assembly coordinate system of the aircraft general assembly site refers to the spatial coordinate system defined by the designer according to the layout of the aircraft general assembly on site. The two methods are: by measuring several public observation points...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com