Remote on-line monitoring method for numerical control equipment

A kind of numerical control equipment, remote technology, applied in general control system, program control, computer control and other directions, can solve problems such as lack of ability and perfect online monitoring, to avoid unnecessary costs, expand the scope of online monitoring, and increase the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

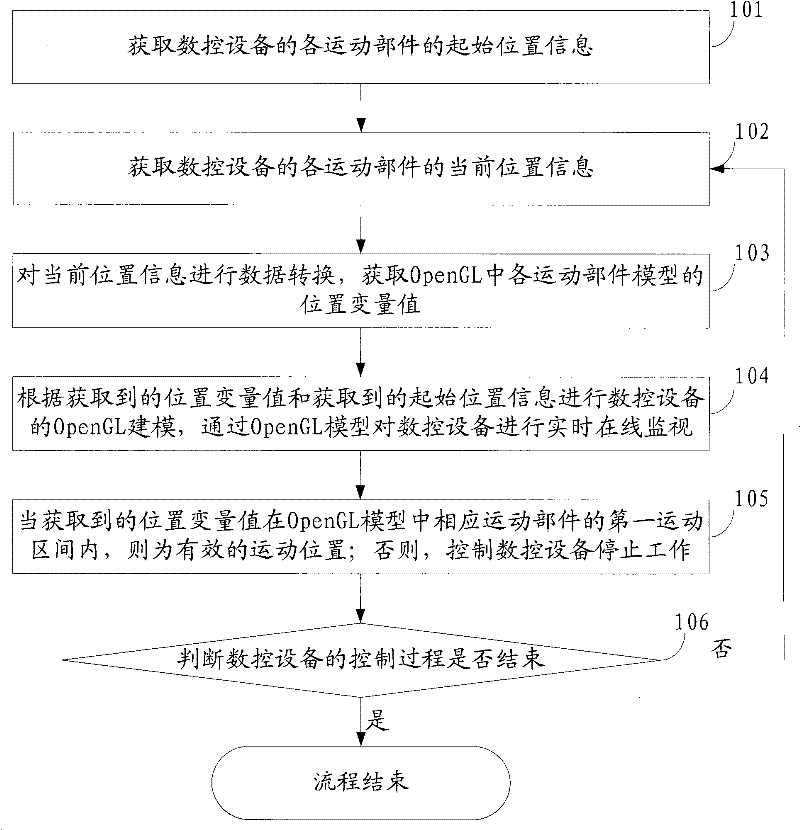

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

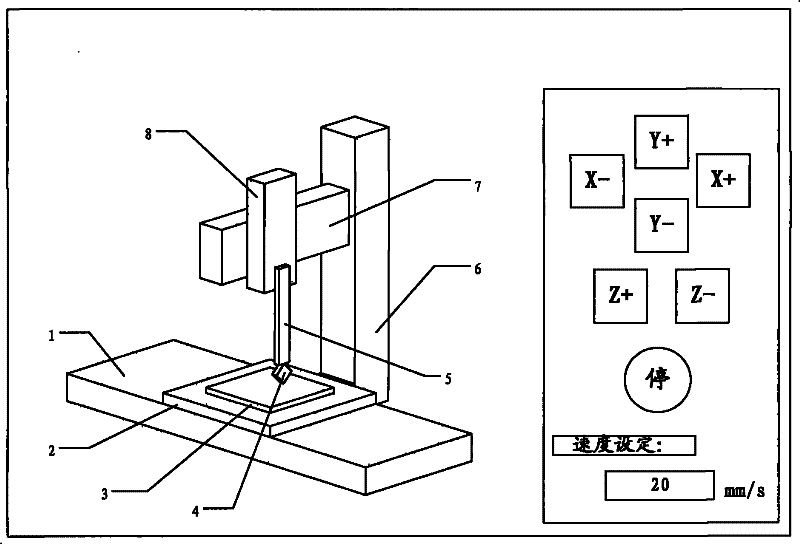

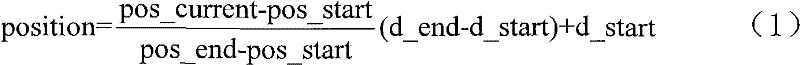

[0029] In order to realize remote real-time online monitoring of numerical control equipment at different locations, expand the range of online monitoring of numerical control equipment, and increase the flexibility of use, the embodiment of the present invention provides a remote online monitoring method for numerical control equipment. The research object is to use IPC (Industry Personal Computer industrial computer) as the control core of CNC equipment, such as CNC machine tools, robots based on PC (Personal Computer, personal computer) control, etc., the development of the control system is based on a certain operating system, usually Windows system or DOS (Disk Operating System, disk operating system) system, adding support and cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com