Minitype electromagnetic broadband vibration energy collector

A vibration energy collection, electromagnetic technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problem of large device size, achieve the effect of large induced electromotive force and low process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

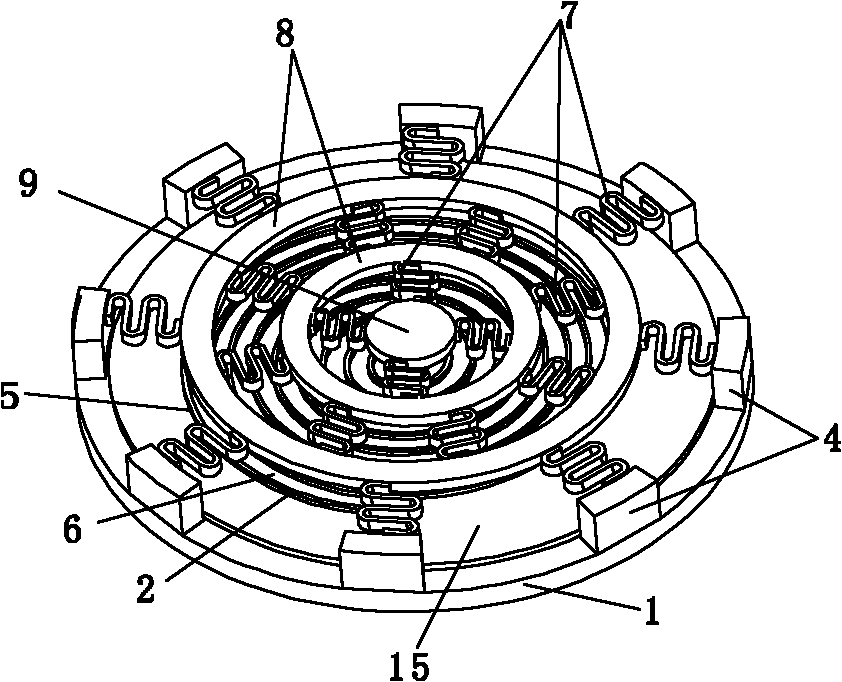

[0032] A miniature electromagnetic broadband vibration energy harvester with three permanent magnets to form a vibration pickup structure

[0033] Such as figure 1 As shown, this embodiment includes: an insulating substrate 1, a planar spiral induction coil 2, a vibration pickup structure 3 and 8 supporting structures 4, wherein: the insulating substrate 1, the planar spiral induction coil 2 and the vibration pickup structure 3 are sequentially lower right On the other hand, the support structure 4 is located outside the planar spiral induction coil 2 and the vibration pickup structure 3 and is fixedly connected to the insulating substrate 1 .

[0034] The insulating substrate 1 is made of quartz or glass.

[0035] The planar spiral induction coil 2 is an induction coil winding structure, specifically a square or circular multi-layer multi-turn spiral metal copper coil 5 combined in a spiral involute mode, wherein the height, width and turns of the metal copper coil 5 The di...

Embodiment 2

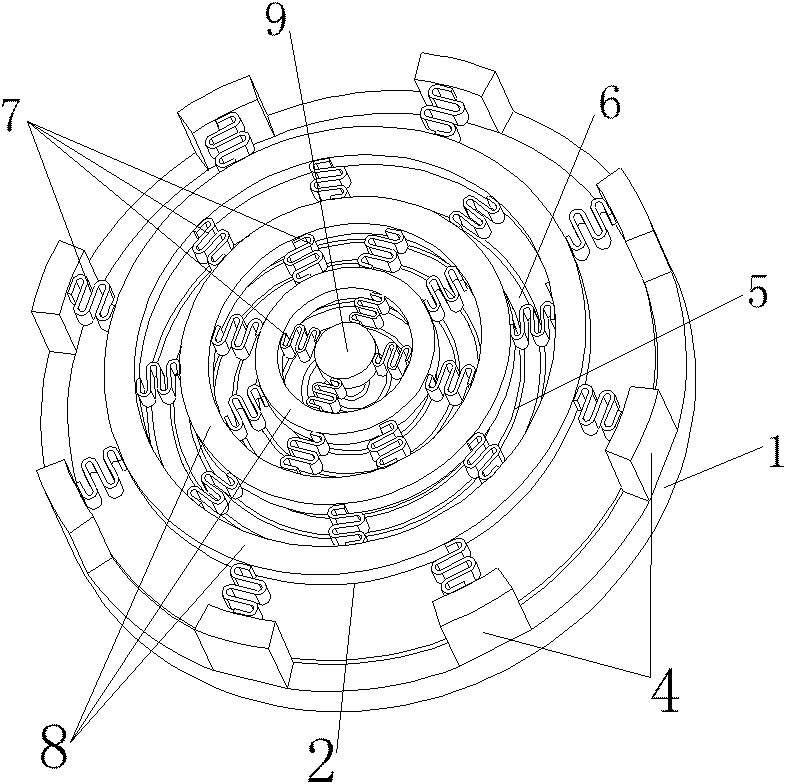

[0047] A miniature electromagnetic broadband vibration energy harvester with four permanent magnets forming a vibration pickup structure

[0048] Such as image 3 As shown, four permanent magnets form a miniature electromagnetic broadband vibration energy harvester with a vibration pickup structure, its structure and principle are basically the same as in Embodiment 1, and the vibration pickup structure 3 includes: 28 serpentine springs 7 , 3 ring-shaped permanent magnets 8 and a center permanent magnet 9, wherein: the center permanent magnet 9 is located at the center of the vibration pickup structure 3, and the 3 ring-shaped permanent magnets 8 are connected to the outside of the center permanent magnet 9 from inside to outside in turn, and 28 snakes The shape spring 7 is radially arranged in the gap between the support structure 4, the annular permanent magnet 8 and the central permanent magnet 9 in turn, so that four vibration peaks can be displayed on the vibration spectr...

Embodiment 3

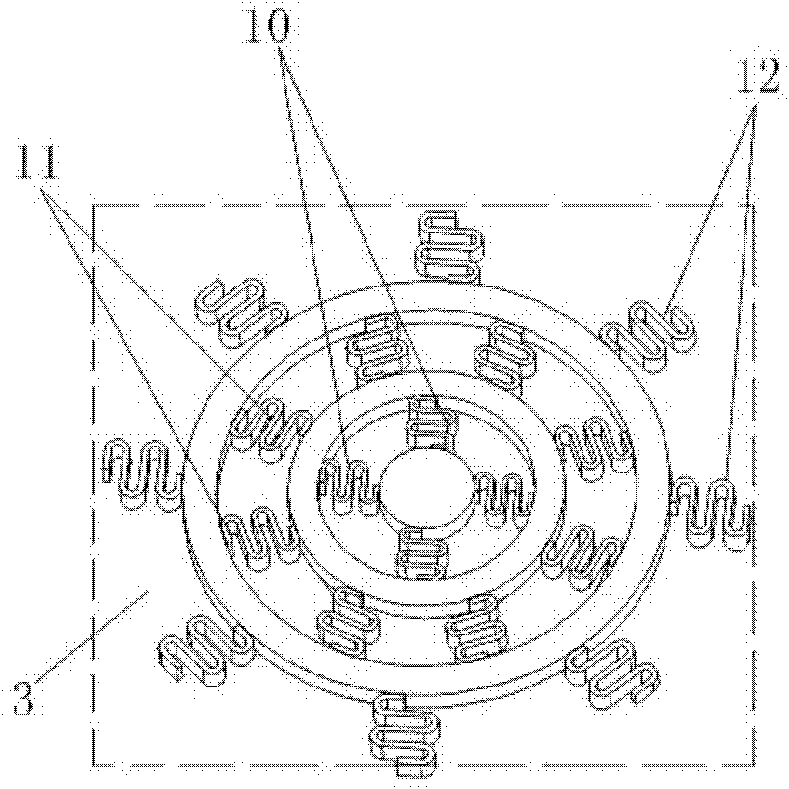

[0050] Such as Figure 4 As shown, this embodiment includes: an insulating substrate 1, a planar spiral induction coil 2, a vibration pickup structure 3, and a support structure 4, wherein: the insulating substrate 1, the planar spiral induction coil 2, and the vibration pickup structure 3 are sequentially lower right to upper Fixedly arranged, the support structure 4 is located outside the planar spiral induction coil 2 and the vibration pickup structure 3 and is fixedly connected with the insulating substrate 1 to form an I-shaped integrated structure.

[0051] The height of the I-shaped integrated structure is 1500 microns, and the amplitude of its fixed frequency is close to that of the planar spiral induction coil 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com