Electric frying pan

An electric frying pan and pot body technology, applied in frying pans, household utensils, applications, etc., can solve problems such as not easy, low degree of automation, loss of food, etc., and achieve the effects of simple operation, simple structure and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

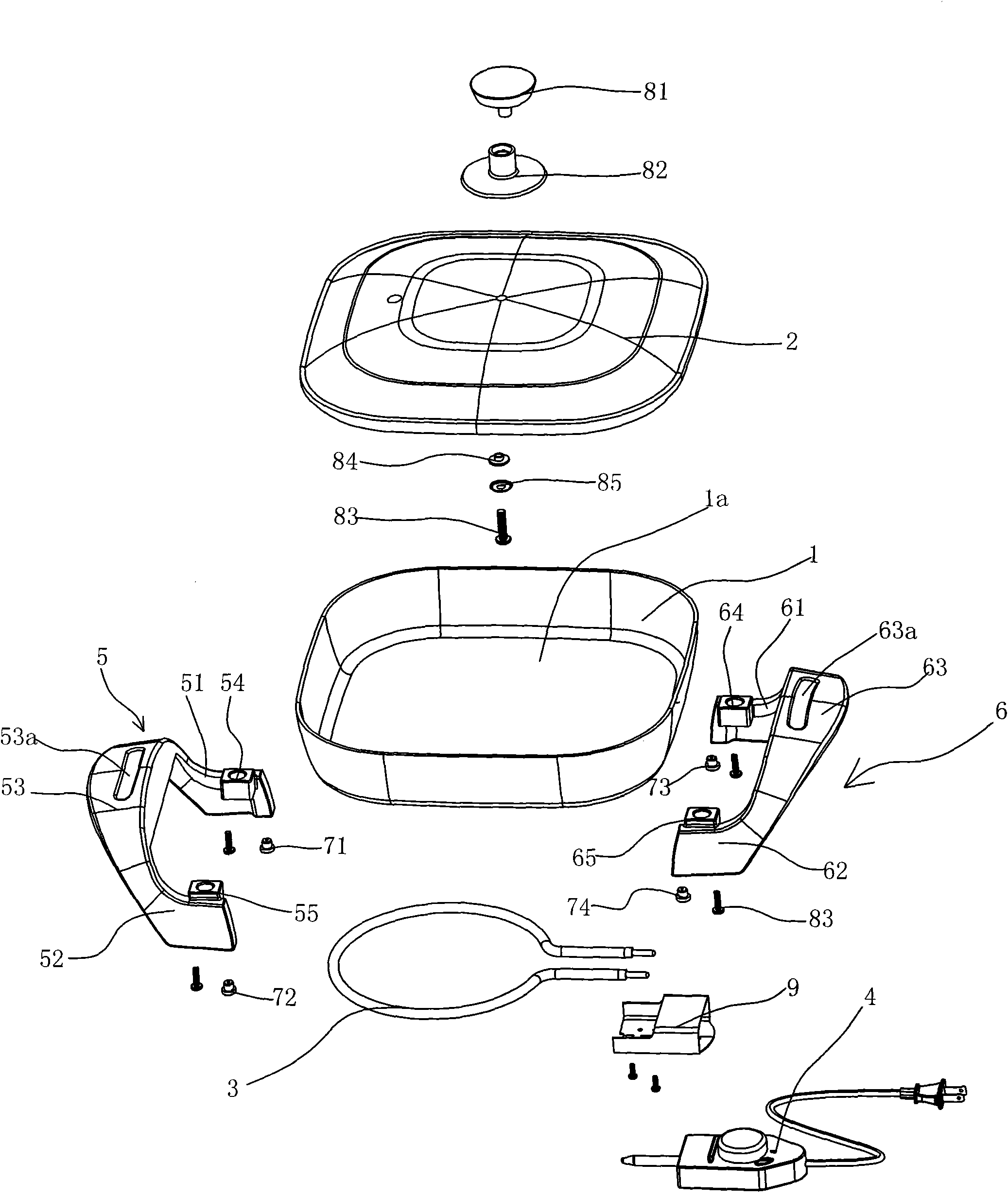

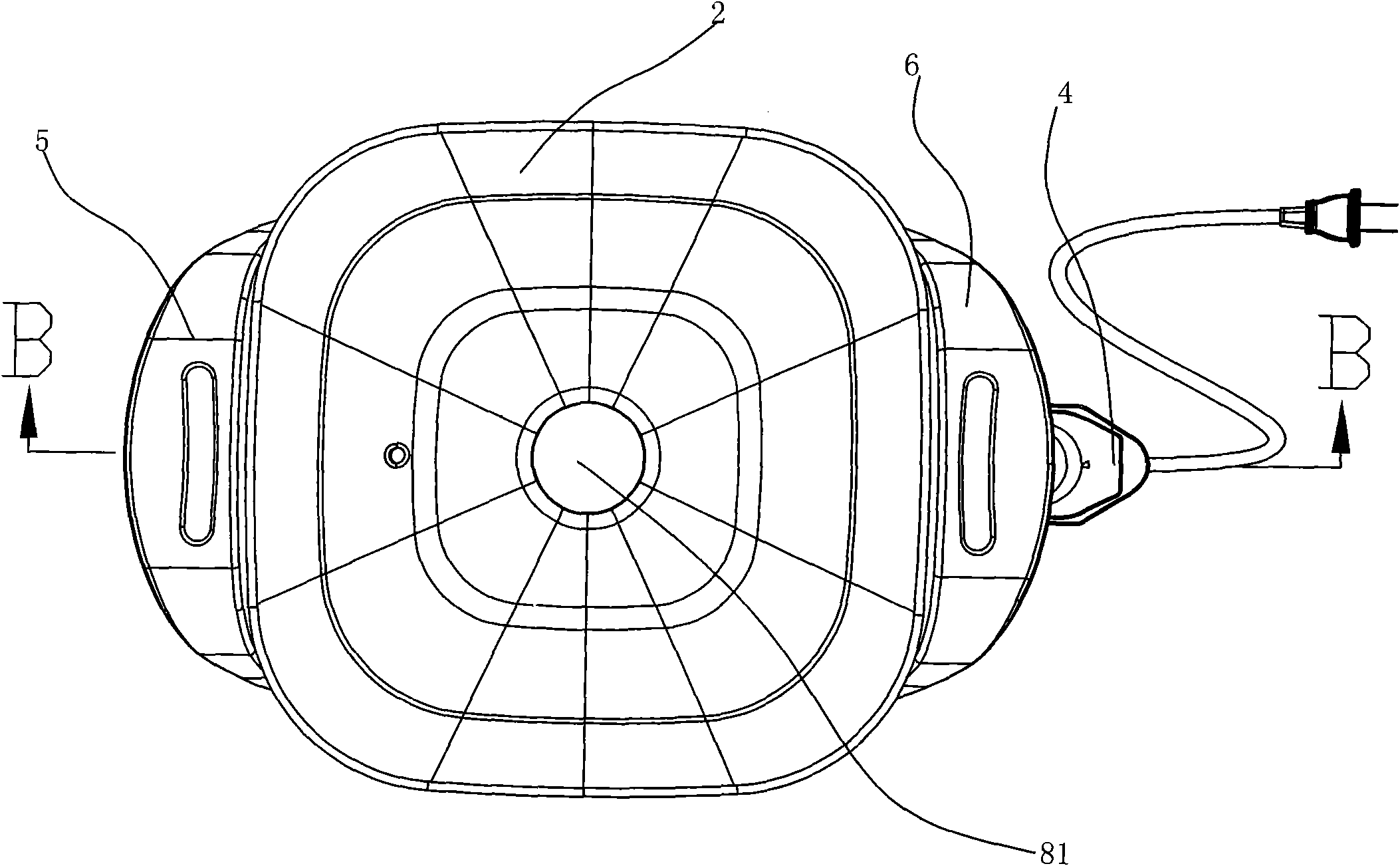

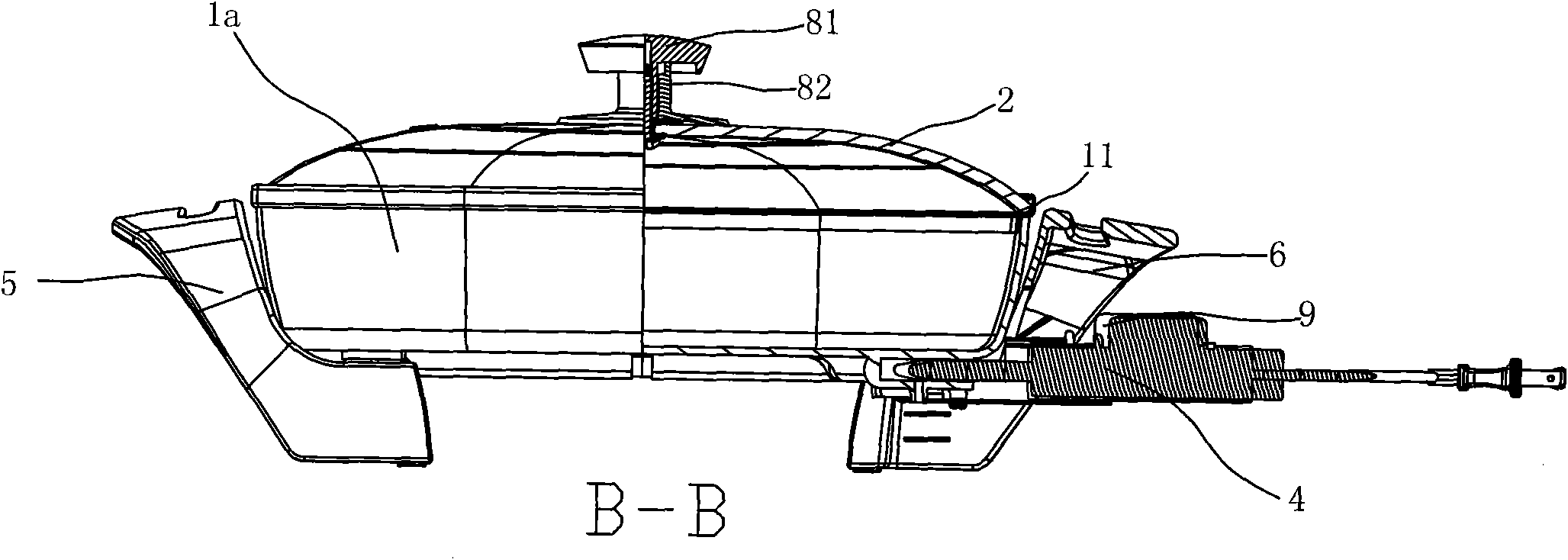

[0022] Such as Figure 1 to Figure 4 As shown in the figure, the pot body 1; the annular flange 11; the frying cavity 1a; the pot cover 2; the heating element 3; the temperature control component 4; A holding body 53; the first arc-shaped square hole 53a; the first supporting base 54; the second supporting base 55; the right handle 6; the third supporting body 61; the fourth supporting body 62; the second holding body 63; the second arc Square hole 63a; the third support seat 64; the fourth support seat 65; the first rubber foot 71; the second rubber foot 72; the third rubber foot 73; the fourth rubber foot 74; handle 81; pressing plate 82; fixing screw 83; Gasket 84; Gasket 85; Fixed cover 9.

[0023] The electric fryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com