Electric blower and electric dust collector including the same

An electric blower and guide technology, applied in the direction of vacuum cleaners, machines/engines, liquid fuel engines, etc., can solve problems such as the difficulty of the impeller 132

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

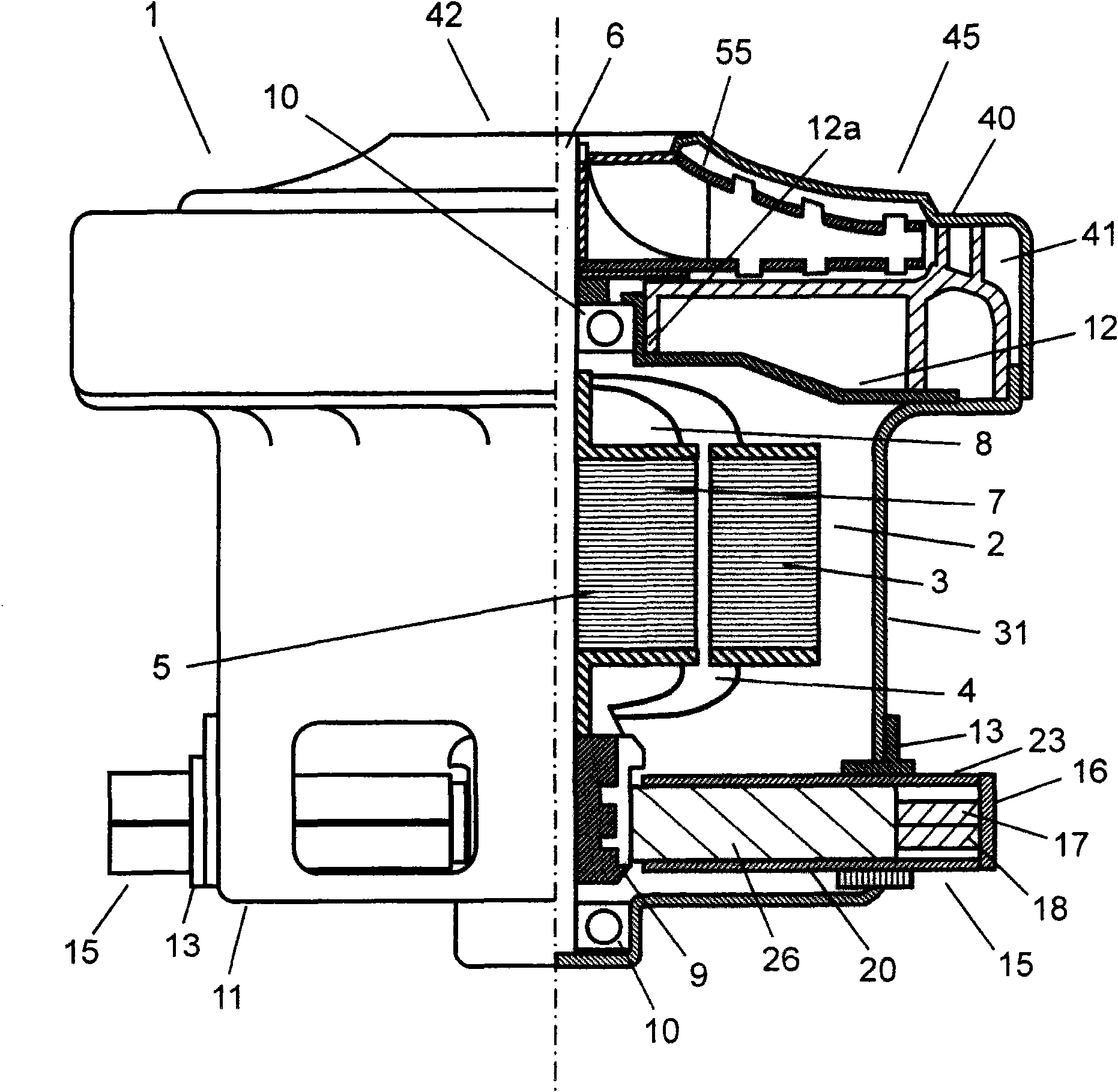

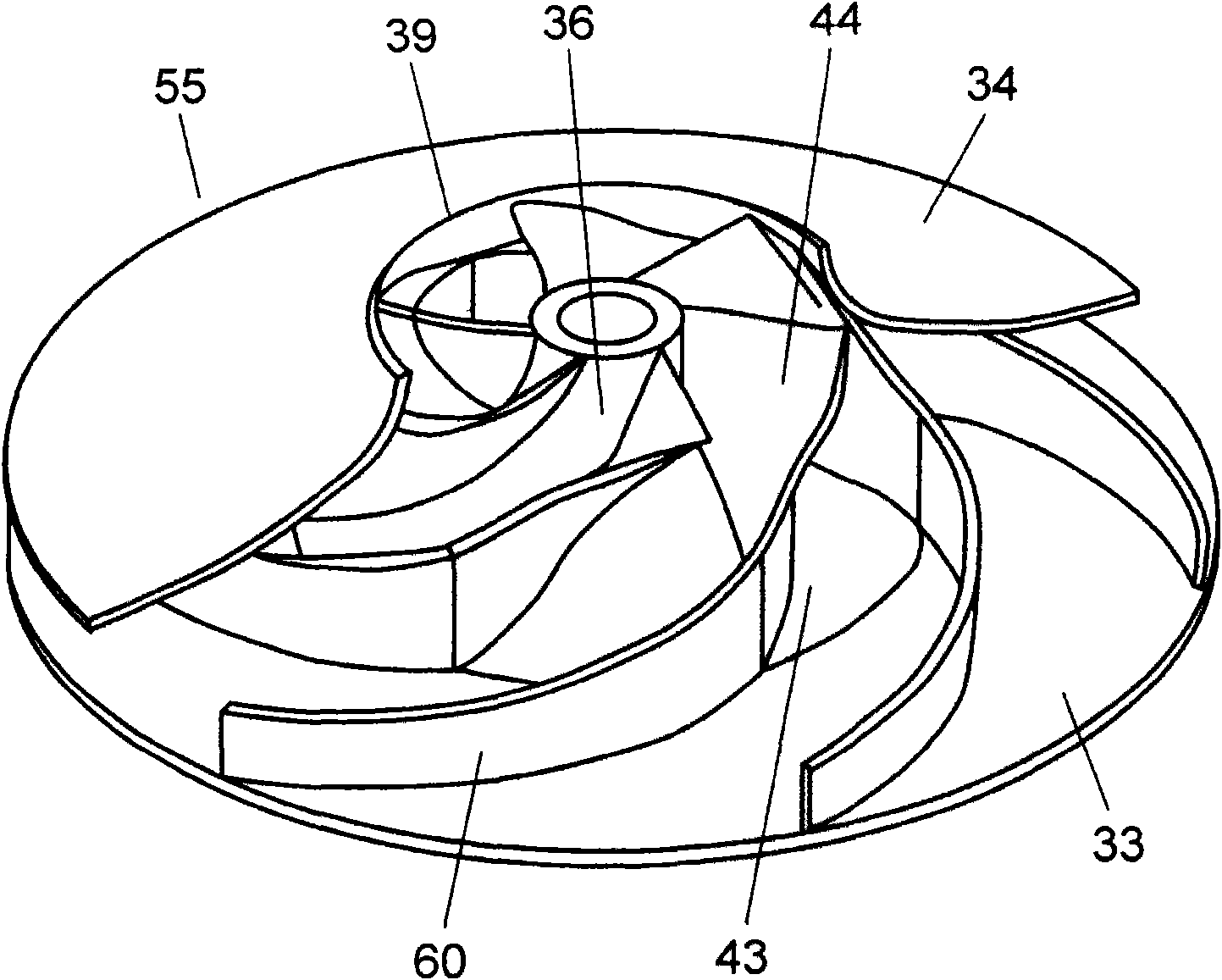

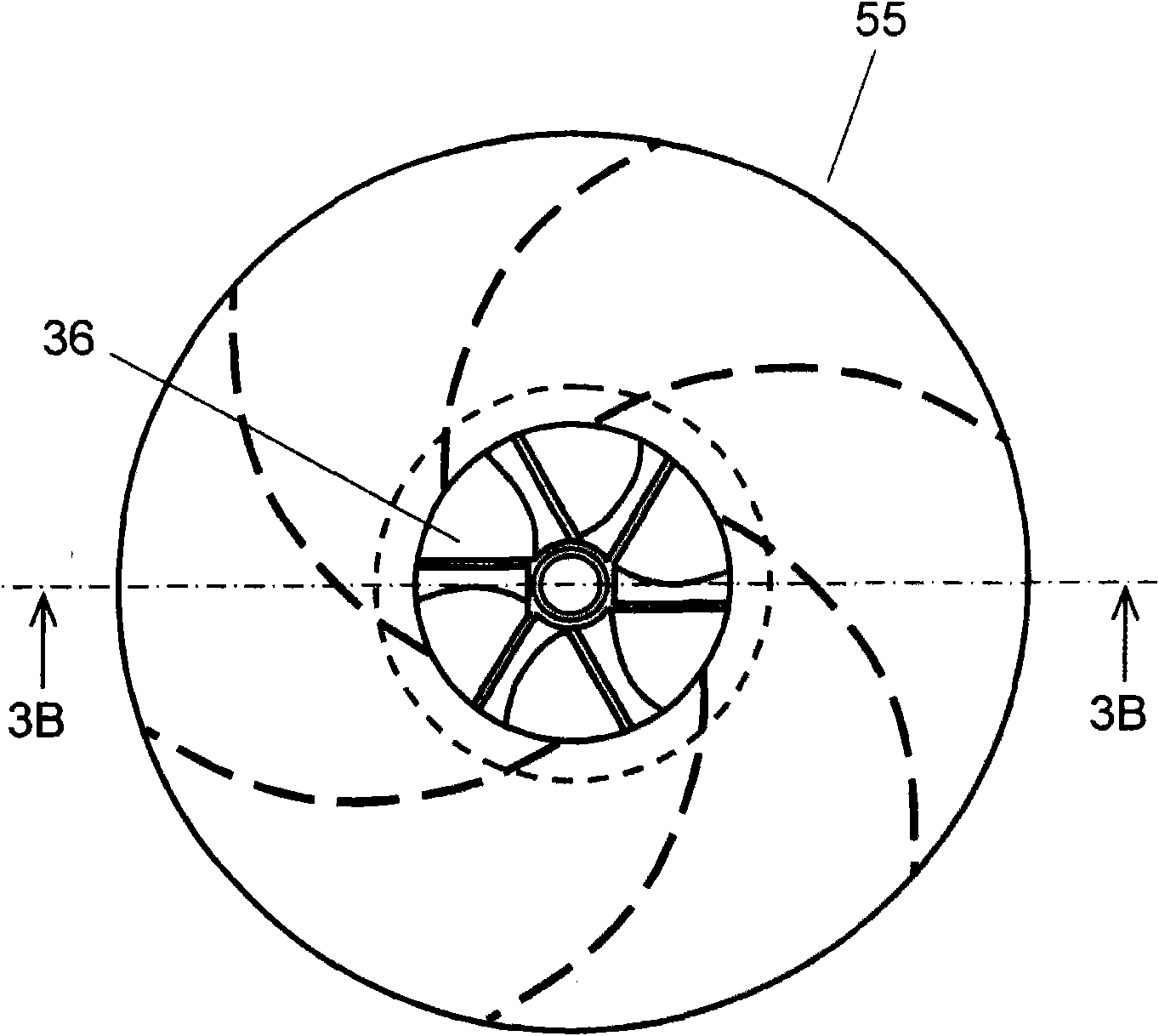

[0042] figure 1 It is a partial cross-sectional view of the electric blower according to Embodiment 1 of the present invention. figure 2 It is a perspective view with a part of the impeller of the electric blower cut away. Such as figure 1 As shown, the electric blower 1 has: the cover body 11 and the bracket 12 constituting the motor 31 ; and the housing 40 constituting the fan unit 45 . The housing 40 is attached to the bracket 12 in an airtight manner.

[0043] The motor 31 has a stator 2 and a rotor 5 . The stator 2 is configured by winding a field winding 4 around a magnetic core 3 . The stator 2 is attached to the inner surface of the casing 11 . The rotor 5 is configured by winding an armature winding 8 around an armature core 7 provided on a shaft 6 . The rotor 5 is rotatably attached to a cover 11 and a bracket 12 via bearings 10 provided at both ends of the shaft 6 . In addition, a commutator 9 is provided coaxially with the shaft 6 on the cover 11 side of ...

Embodiment approach 2

[0058] Image 6 It is a perspective view of the blade body of the impeller according to Embodiment 2 of the present invention. Figure 7 It is a perspective view of the blade of the impeller of this embodiment. In addition, the same code|symbol is attached|subjected to the same component as Embodiment 1, and detailed description is abbreviate|omitted.

[0059] Such as Image 6 with Figure 7 As shown, the blade 60 of this embodiment has a blade body 65 made of a metal plate, and a resin body 62 integrally formed on the outside of the blade body 65 . The blade body 65 has a plurality of openings 66 penetrating in the thickness direction. When the resin body 62 is integrally molded to the blade body 65 , the opening 66 is filled with the resin body 62 .

[0060] Thereby, the adhesion strength of the resin body 62 to the blade body 65 increases. That is, the resin body 62 is hard to peel off from the blade body 65 . Furthermore, the blade body 65 can be reduced in weight b...

Embodiment approach 3

[0062] Figure 8 It is a perspective view of the blade of the impeller in Embodiment 3 of this invention. In addition, the same reference numerals are assigned to the same components as those in Embodiment 1, and detailed description thereof will be omitted.

[0063] Such as Figure 8 As shown, the blade 70 of this embodiment has a blade body 61 and a resin body 72 integrally formed on the outside of the blade body 61 . In addition, as indicated by R in the figure, the cross section of the end portion of the resin body 72 has an arc shape. Figure 9A is a cross-sectional view of the riveted part of the impeller 55 . Figure 9B It is a sectional view other than the caulking part of the impeller 55 . The arc-shaped ends of the resin body 72 are in contact with the front guard 34 and the rear guard 33 . The arc shape of the resin body 72 is in smooth contact with the inner surfaces of the front shield 34 and the rear shield 33 .

[0064] When the electric blower 1 is energi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com