Rubber-tyred gantry crane with suspension crane and construction method thereof

A gantry crane and tire-type technology, which is applied in the direction of trolley cranes, cranes, traveling mechanisms, etc., can solve the problems of insufficient flexibility in lifting heavy objects, deficiencies in transportation flexibility, and insufficient load capacity, so as to improve operating efficiency and facilitate on-site Good effect of installation and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

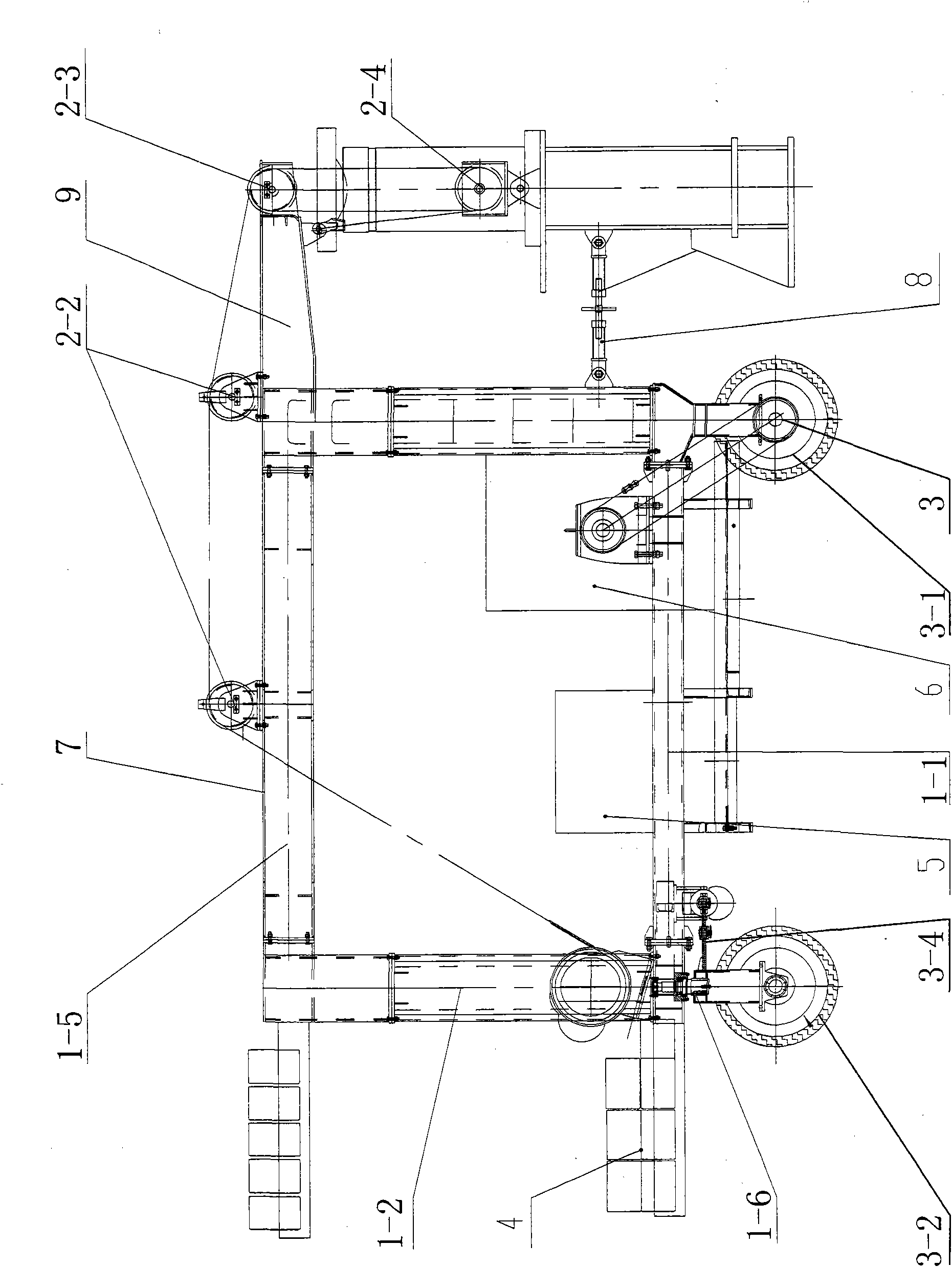

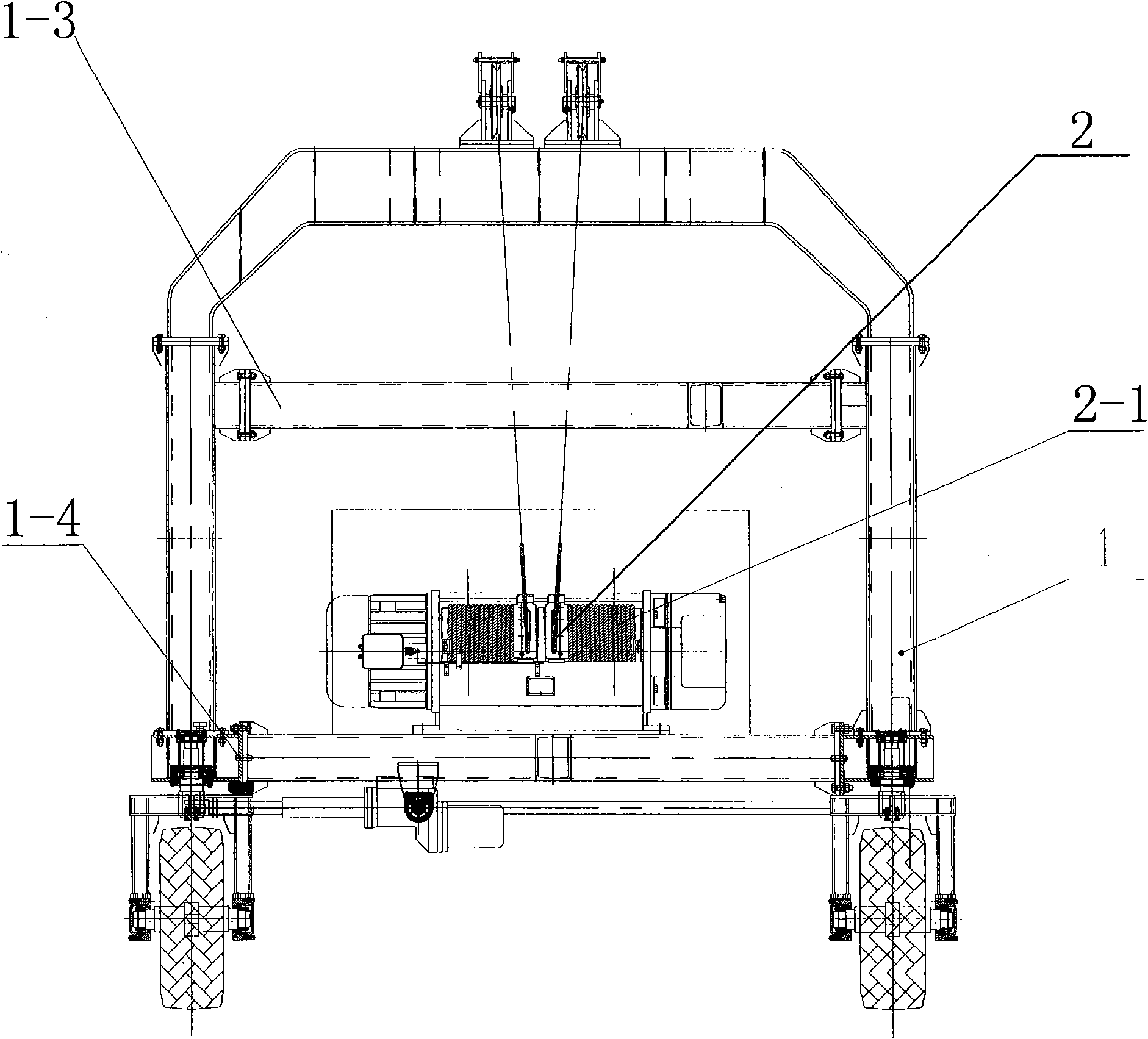

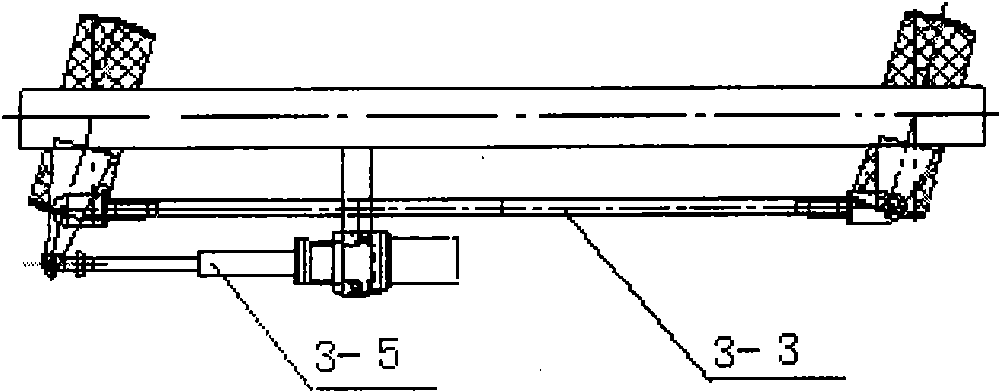

[0023] Such as figure 1 , 2 , 3, the present invention consists of a gantry 1 and a hoisting device 2 installed on the gantry 1, wherein a traveling mechanism 3 is provided at the bottom of the gantry 1, and a balance counterweight is installed at the rear end of the gantry 1 4. The gantry 1 is also provided with a generator set 5 and an electrical control device 6 connected with the lifting device 2 and the traveling mechanism 3 .

[0024] Described gantry frame 1 is made up of span beam 1-1, four upright columns 1-2, upper connecting beam 1-3, lower connecting beam 1-4, connecting crossbeam 1-5, walking wheel frame 1-6, wherein four The uprights 1-2 are distributed in a rectangle, and the tops of the four uprights 1-2 are provided with connecting crossbeams 1-5 via bolts, and the bottom ends between the front and rear adjacent uprights are provided with cross beams 1-1 via bolts, An upper connecting beam 1-3 and a lower connecting beam 1-4 are installed by bolts between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com