Stepless mechanical lifting gear

A lifting device and mechanical technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of easy damage to the motor starting circuit, slow lifting speed, high cost, and achieve the effects of fast and comfortable use, improved work efficiency, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

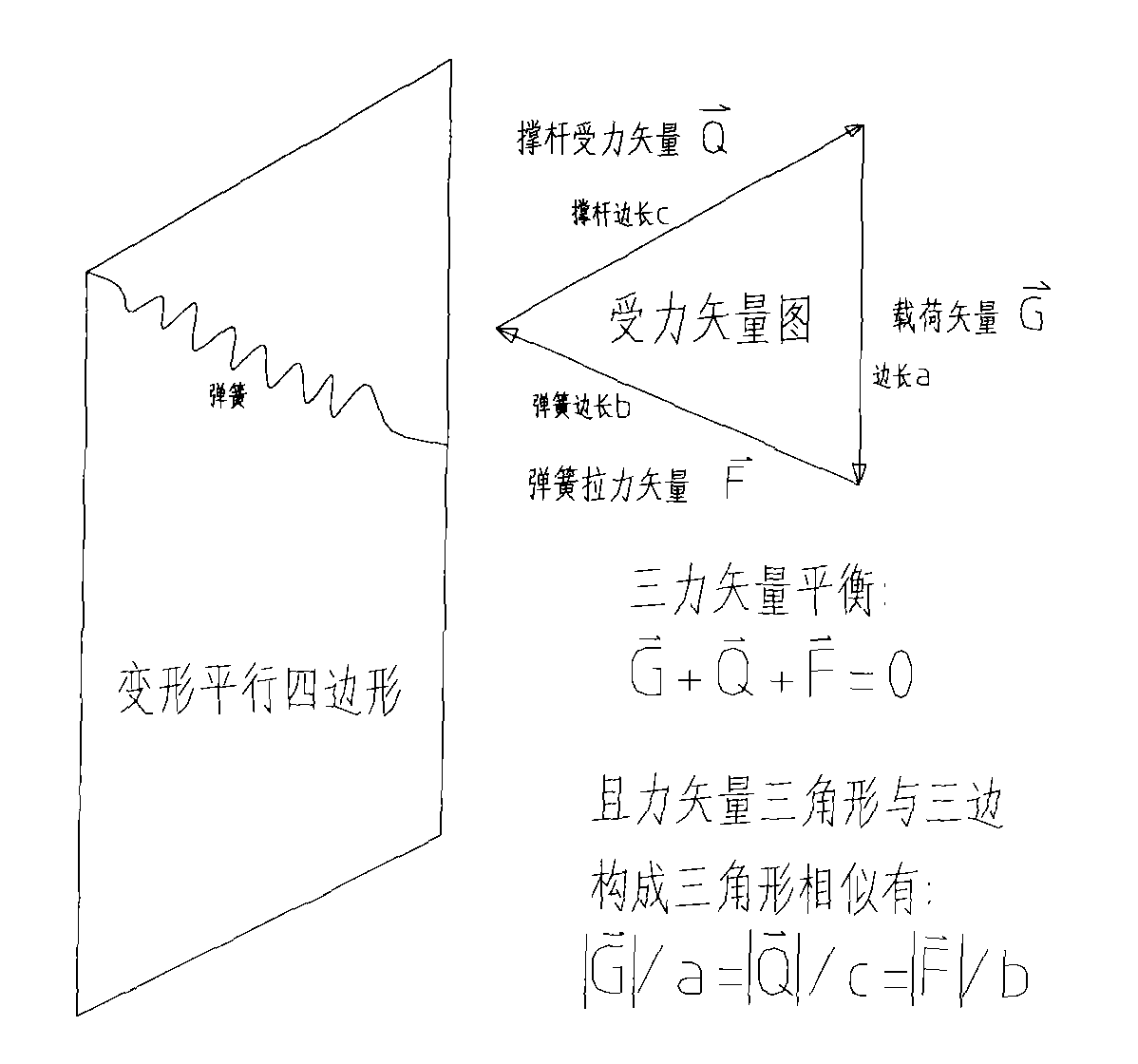

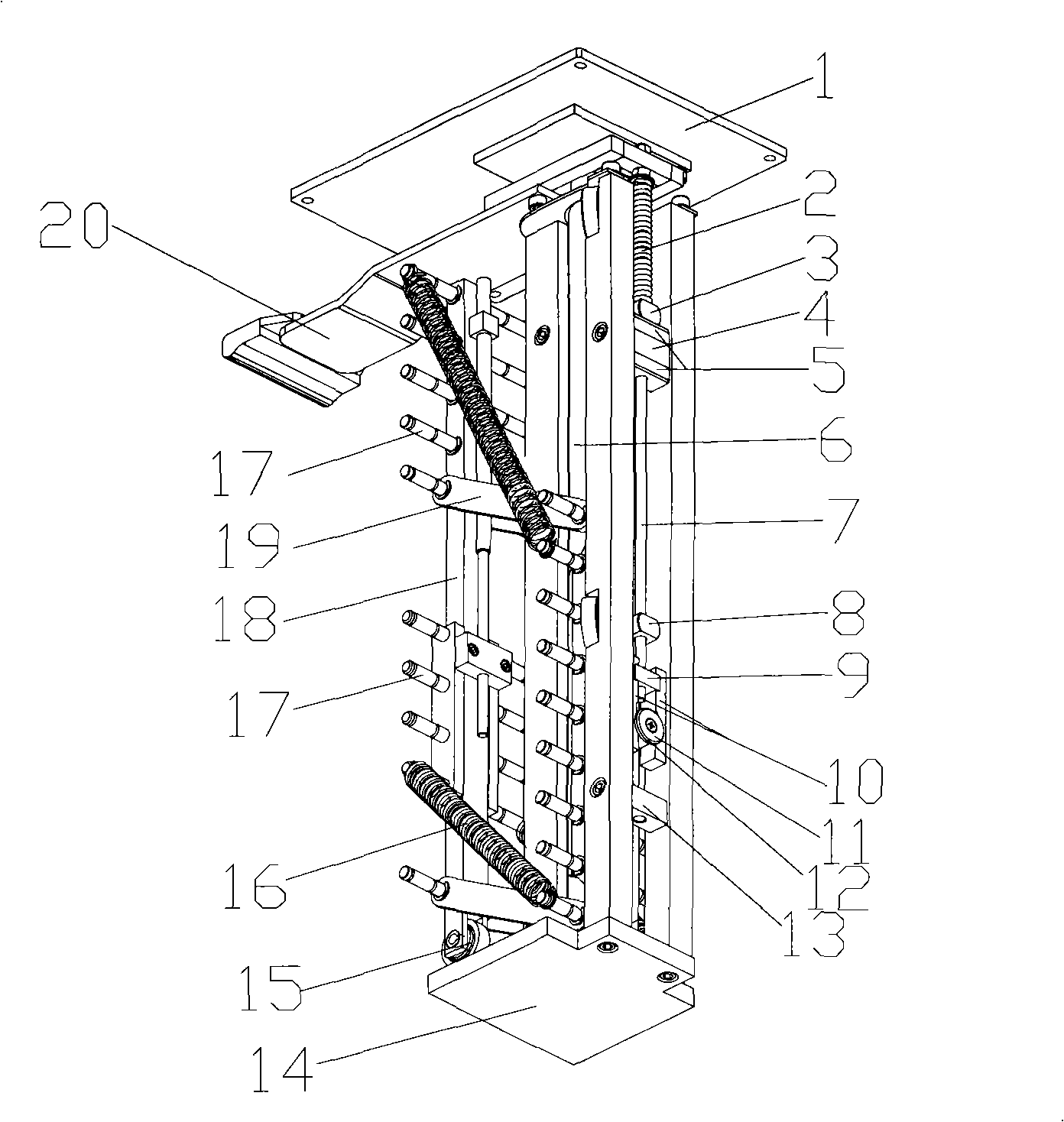

[0025] like Figure 1-7 Shown: 1 is the end panel, 2 is the locking spring, 3 is the upper positioning block, 4 is the upper block, 5 is the buffer plate, 6 is the lifting column, 7 is the locking round rod, 8 is the lower positioning block, 9 10 is the locking piece, 11 is the locking limit piece, 12 is the locking ring, 13 is the lower block, 14 is the support base, 15 is the bearing, 16 is the spring, 17 is the spring hanger Rod, 18 is a deformation support column, 19 is a connecting rod, 20 is a handle, 21 is a rear support column, 22 is a front support column, 23 is a rolling rail, 24 is a fixed bolt, 25 is a threaded screw mandrel, and 26 is a connecting block. The 27th is a lift regulating seat, the 28th is a table top, the 29th is a lifting structure, the 30th is a base, the 31st is a shell, and the 32nd is a locking bolt.

[0026] The stepless mechanical lifting device of the present invention includes a table top 28, a lifting structure 29 and a base 30, the lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com