Method for manufacturing prefabricated hole site vacuum glass

A vacuum glass and manufacturing method technology, applied in glass manufacturing equipment, glass molding, glass reshaping, etc., can solve problems such as scrapping, glass scrapping, and errors in nailing and same hole, so as to simplify the process and avoid installation errors , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

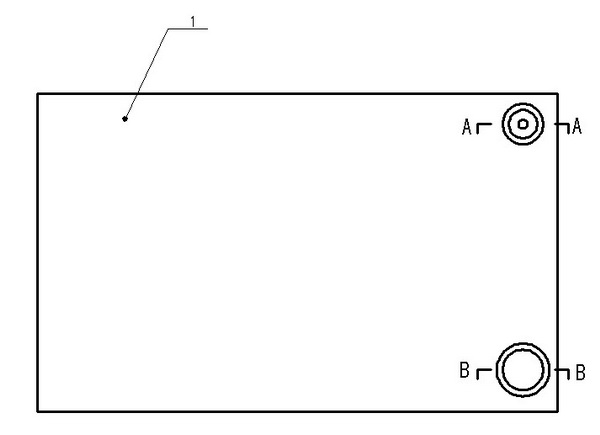

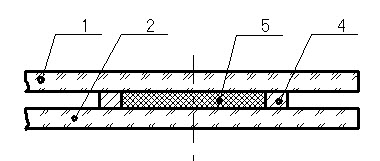

[0024] Example 1, see figure 1 , figure 2 , image 3 .

[0025] A method for manufacturing prefabricated hole position vacuum glass, the steps are:

[0026] (1) Set the prefabricated hole position on the substrate glass between the upper glass 1 and the substrate glass 2, and place a sealing material on the set prefabricated hole position. The shape of the sealing material can be a ring 3, or Wafer 5 or other shapes, the sealing material is made of low melting point glass powder or resin glue, which can be prefabricated, or can be directly made at the prefabricated hole position of the substrate glass;

[0027] (2) After placing the sealing material, place a barrier 4 on the outer periphery of the ring or disc to shape the sealing material. The barrier is a high-temperature-resistant barrier plate, strip or block, or a high-temperature-resistant soft wire and Sheet.

[0028] (3) Put it into a heating furnace to heat, and then vacuumize to obtain the finished vacuum glass...

Embodiment 2

[0031] Example 2, see Figure 4 , Figure 5 .

[0032] In this embodiment, no barrier is placed on the outer periphery of the ring or the disc, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com