Crystal taking frame convenient for taking monocrystal bar

A technology of single crystal ingot and crystal frame, which is applied in the direction of crystal growth, post-processing equipment, and post-processing, etc. It can solve problems such as unstable center of gravity, long transportation, and heavy crystal ingot weight, so as to avoid direct contact and inaccurate center of gravity The effect of stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

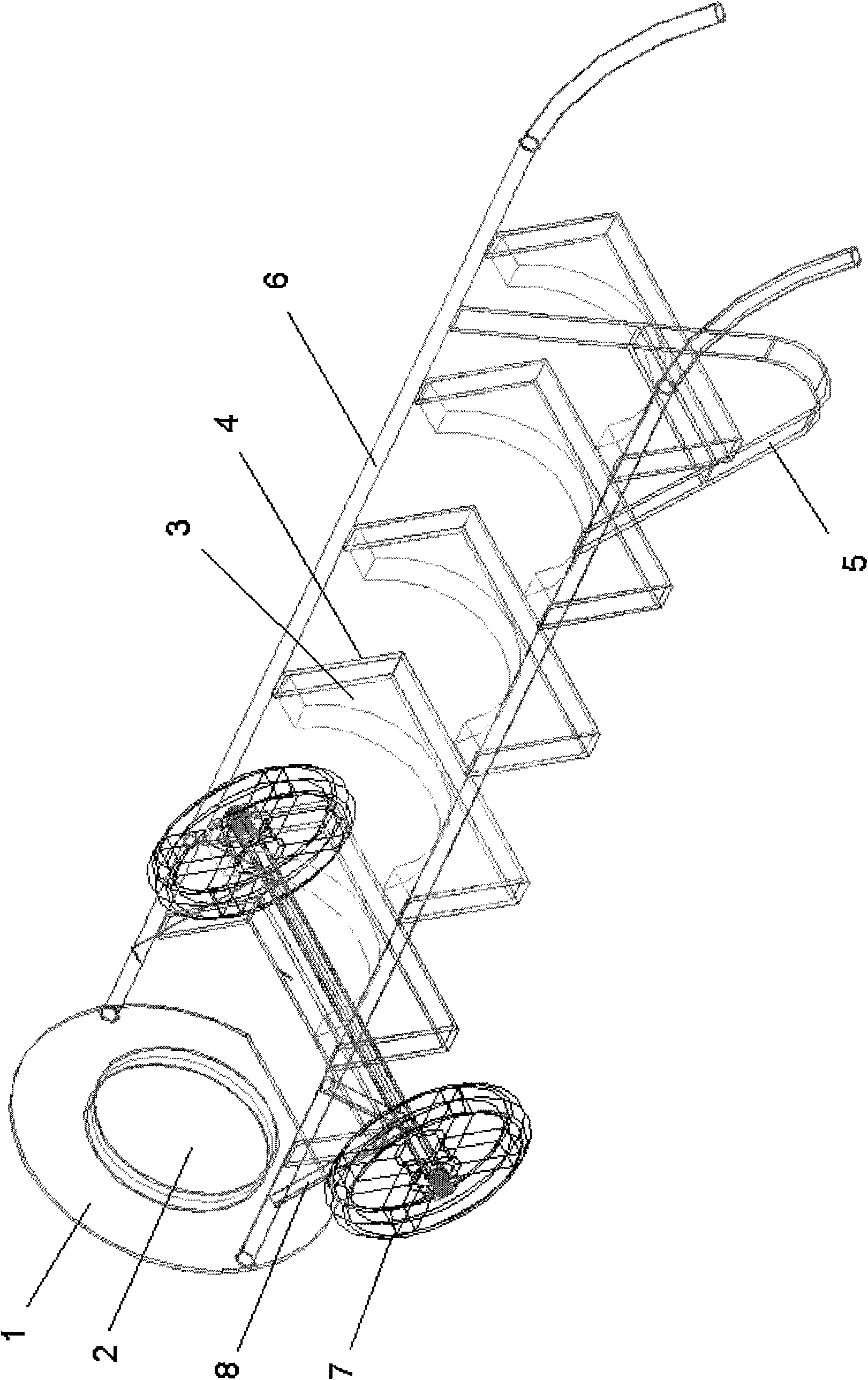

[0016] like image 3 As shown: the present invention includes a base 1 and a wooden backing plate 2 arranged on the base 1, two parallel rods 6 are fixed perpendicular to the base 1 on the base 1, and a plurality of wooden baffles are arranged between the two rods 6 3. The wooden baffle 3 is parallel to the base 1, and the upper part of the wooden baffle 3 is provided with a unified arc-shaped gap. A plurality of outline frames 4 are fixed between two rods 6 , and the wooden baffle 3 is embedded in the outline frames 4 . Wherein, the base 1, the rod 6 and the profile frame 4 can be welded with metal materials. The crystal rod is placed in the arc-shaped gap of the wooden baffle 3 , and the tail part bears against the wooden backing plate 2 .

[0017] The contact part is increased by taking the crystal frame and the crystal rod, and more wooden parts are added to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com