Mounting method of track fundamental equipment bracket of tamping coke oven SCP (Stamping, Charging and Pushing) machine

A technology for basic equipment and tamping coke ovens, which can be applied to tracks, roads, hoisting devices, etc., to solve problems such as large installation errors, and achieve the effects of high installation accuracy, simple production, and accelerated installation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

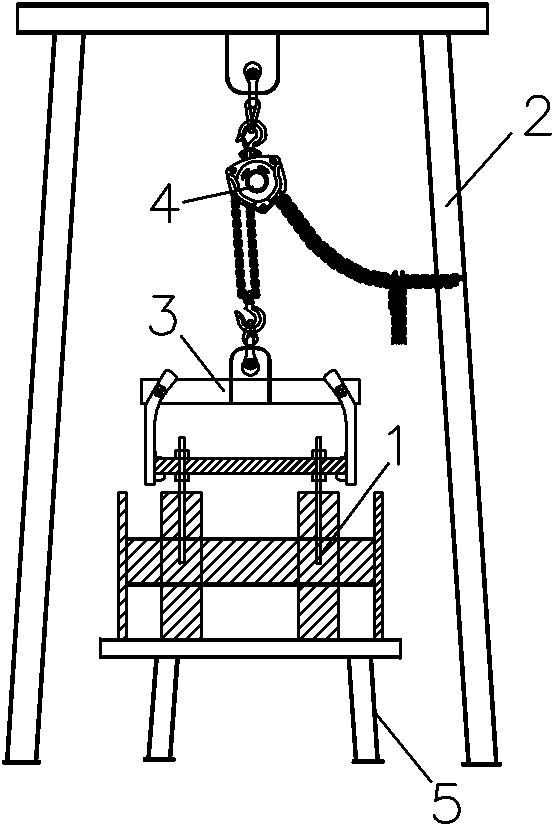

[0022] The invention provides a method for installing the track foundation equipment support of the tamping coke oven SCP machine, see figure 2 , the method is: firstly place the prefabricated bench support 5 flatly on the hoisting point of the SCP machine track basic equipment support 1, then hoist the SCP machine track basic equipment support 1 on the bench support 5 with a crane, Then use the portal hanger 2 and the chain block 4 to carry out the installation and adjustment of the SCP machine track basic equipment support 1 under the cooperation of the hoisting fixture 3, thereby realizing the high-precision installation requirements of the SCP machine track basic equipment support.

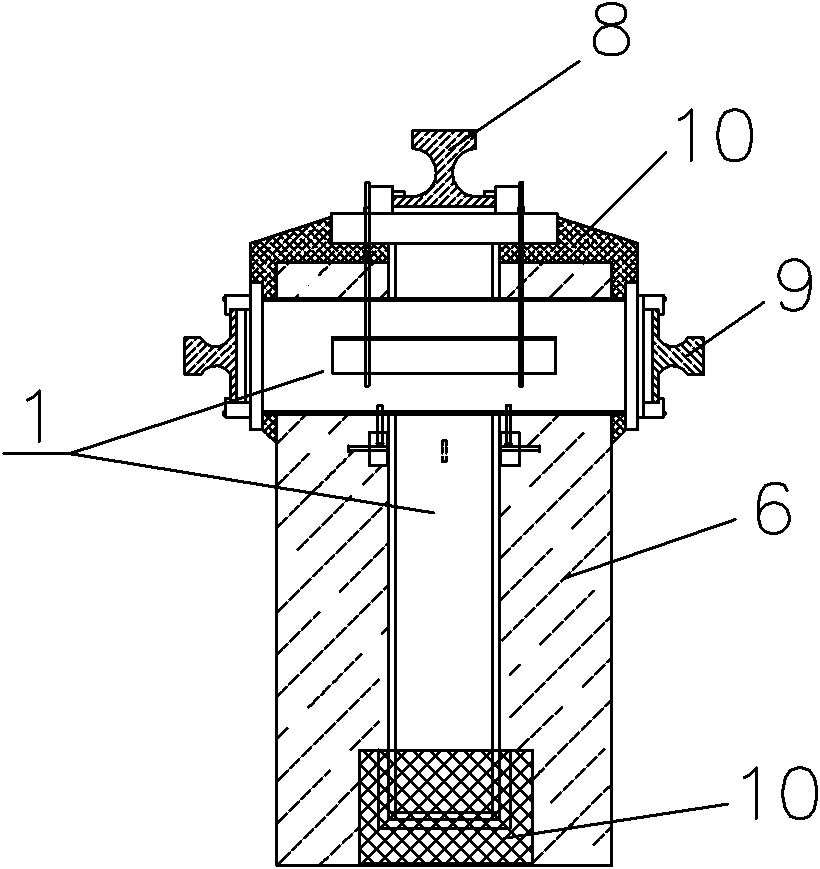

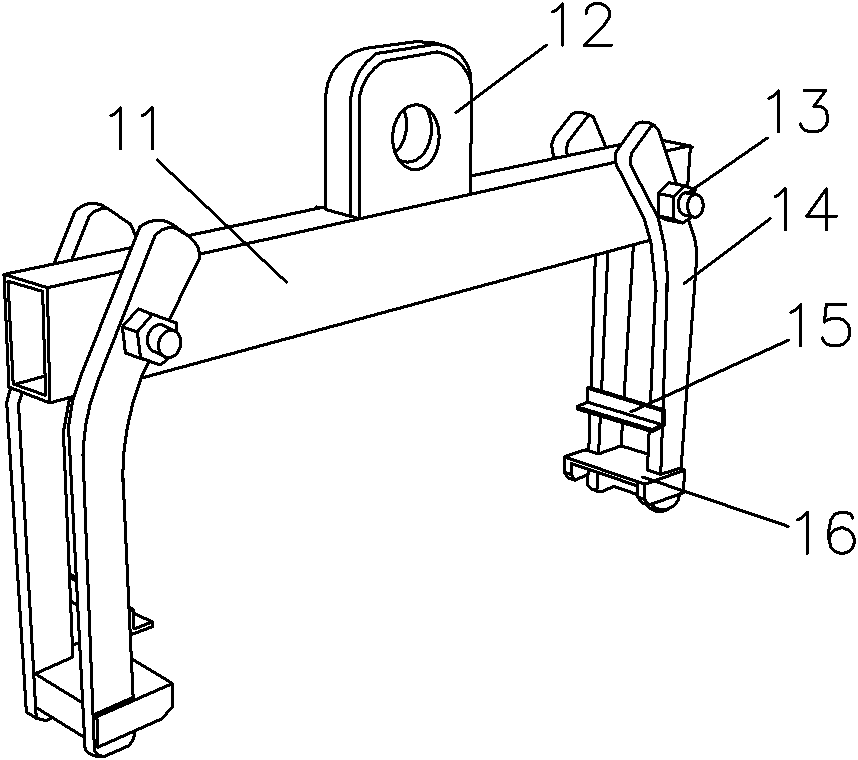

[0023] see Figure 1 to Figure 5 , the present invention adopts the method compris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com