Discharge assisting and liquid increasing device of oil pumping machine

A technology of pumping unit and liquid device, which is applied in the field of pumping unit auxiliary discharge and liquid booster, can solve the problems of affecting the oil production volume of oil wells, increasing maintenance costs, pump barrel leakage, etc., so as to reduce the leakage in the pump barrel and improve the oil well The effect of fluid production and reduction of plunger load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

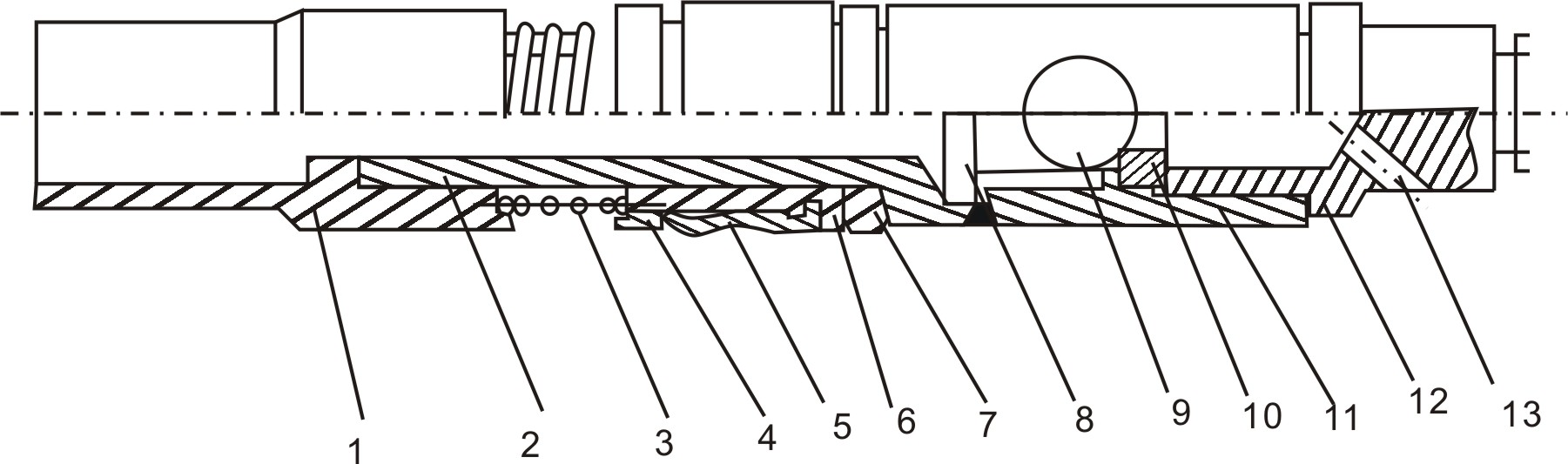

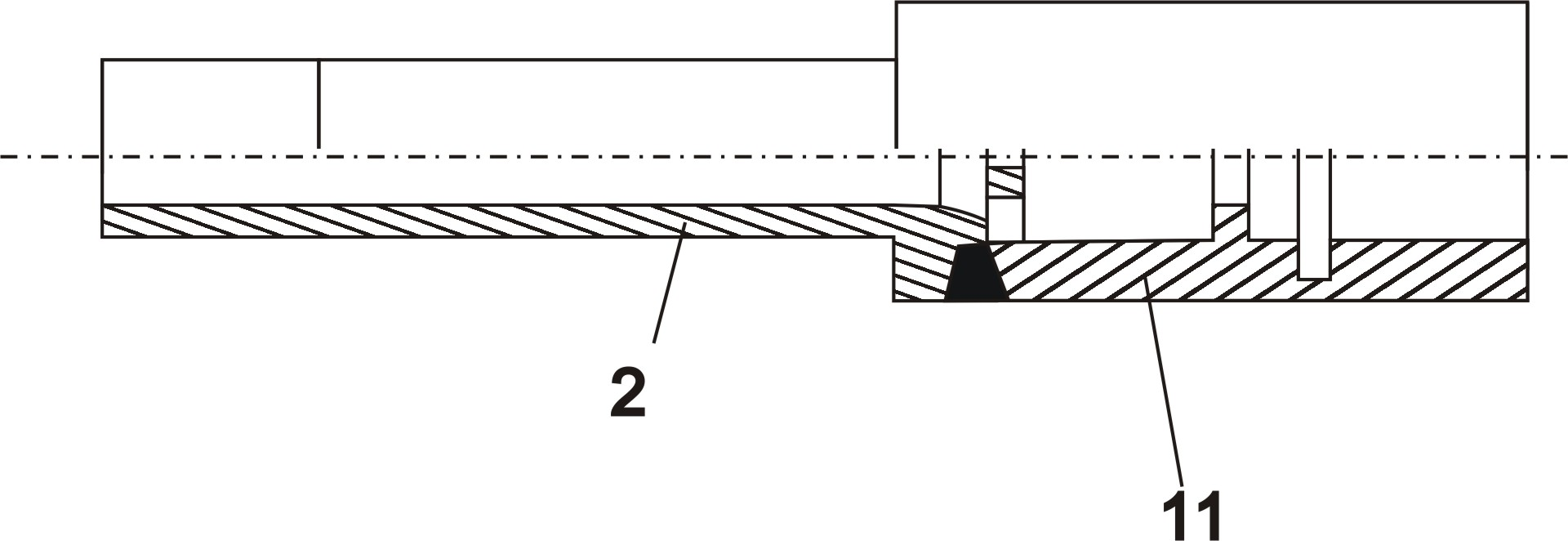

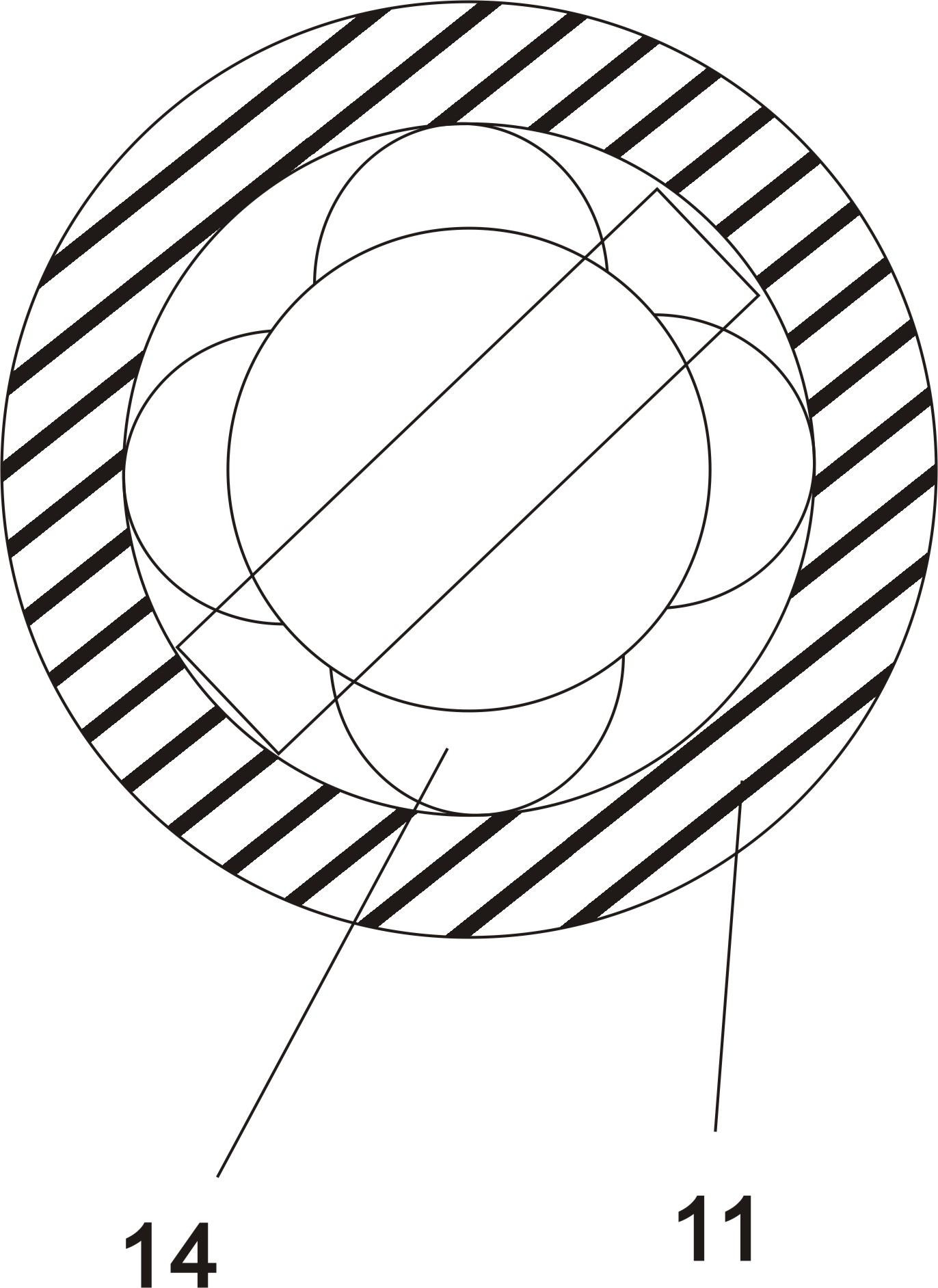

[0011] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. As shown in the figure, a liquid booster for pumping unit is mainly composed of upper joint 1, core pipe 2, 11, spring 3, sealing bowl assembly, sealing ring 7, steel ball 9, ball seat 10 and lower joint 12 The core tube is composed of core tube body A and core tube body B, which are plugged and fixedly connected to form a whole core tube. The upper end of the core tube body A is threaded with the upper joint, and the core tube body A is equipped with a The sealing frame 6 is equipped with a bowl-shaped sealing expansion ring 5, and the lower part of the sealing expansion ring is provided with a sealing ring. Then, the upper part of the inner hole of the core tube body B is provided with a ball stopper 8, the lower part of the inner hole of the core tube body B is provided with a ball seat, and a steel bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com