Crankcase assembling surface seal structure

A sealing structure and crankcase technology, applied in the crankcase field, can solve the problems of high dependence on sealing materials and unreliable sealing, and achieve the effects of simple production, increased sealing performance, and enhanced sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

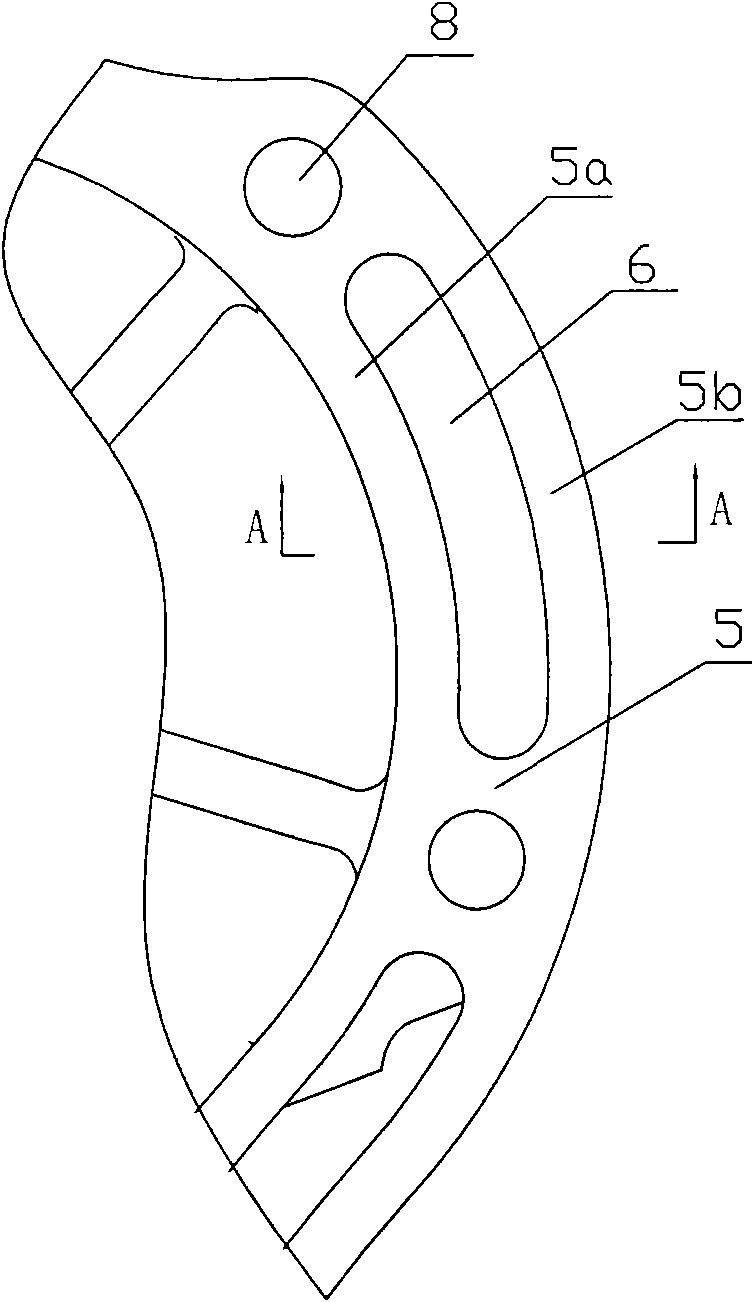

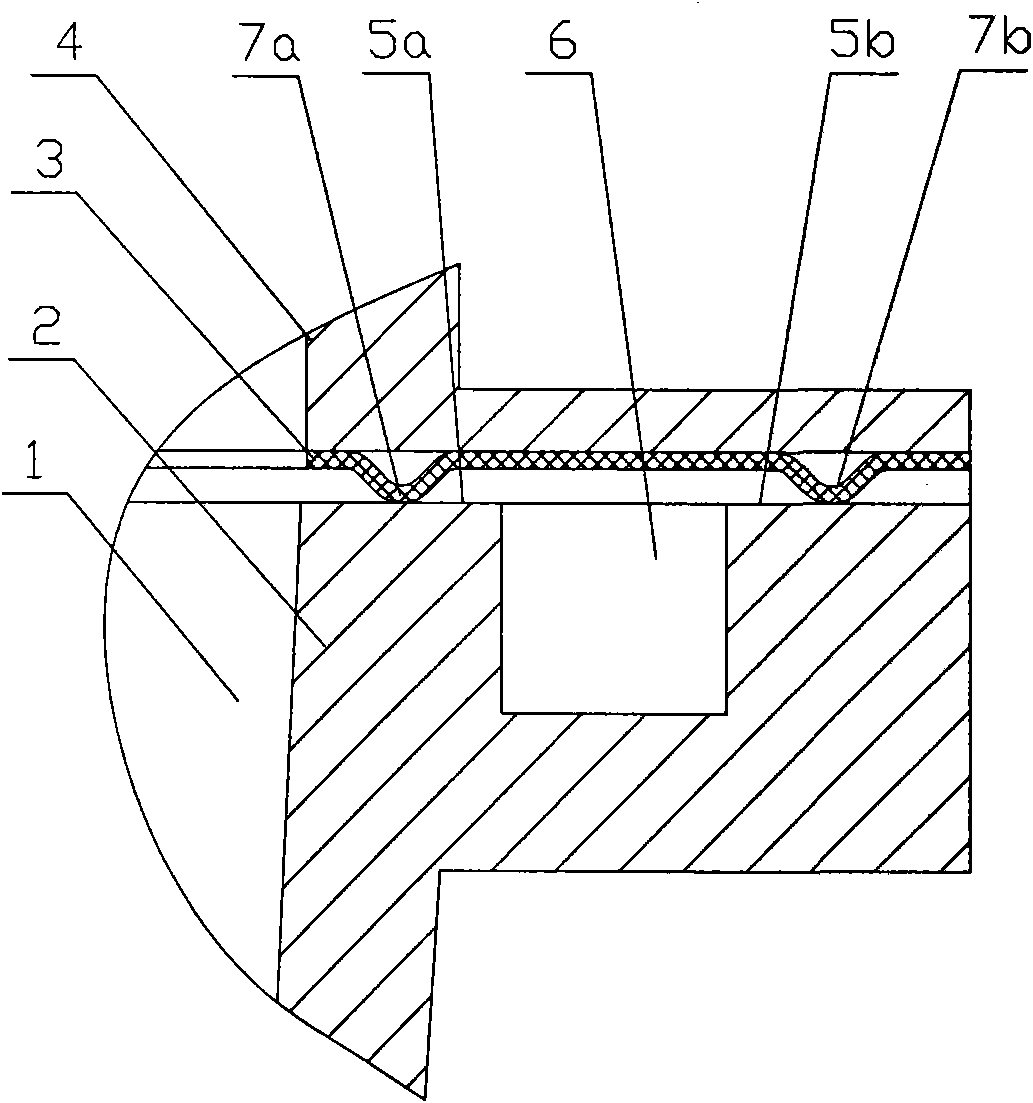

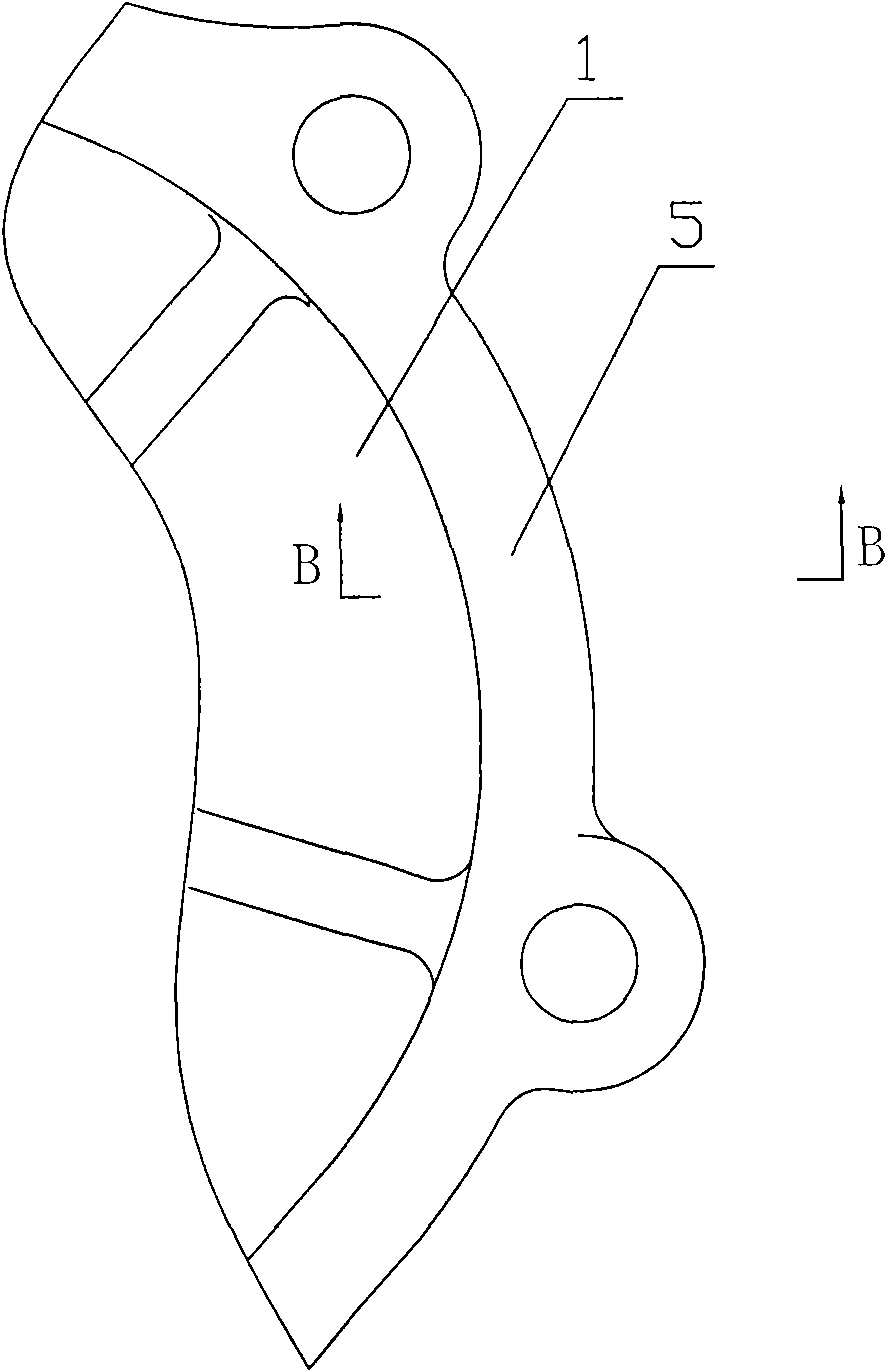

[0016] refer to figure 1 and figure 2 , the crankcase surface sealing structure, including the crankcase body 4 and the crankcase cover 2, the crankcase body 4 and the crankcase cover 2 are connected by a flange, and the sealing surface is formed on the contact surface of the crankcase body 4 and the crankcase cover 2 5. Form a crankcase inner cavity 1 isolated from the outside world. There is engine oil for lubricating parts in the crankcase inner cavity 1, and combustible gas leaked in the crankcase inner cavity in the cylinder. The engine oil and combustible gas form a mixed oil gas. The end surface of the crankcase cover 2 in contact with the crankcase body 4 is provided with several grooves 6 , the grooves 6 are arc-shaped, and the arc-shaped direction of the grooves is the same as the arc-shaped direction of the sealing surface 5 . The cross-section of the groove 6 is rectangular, or the cross-section of the groove is V-shaped, of course, it can also be grooves of oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com