Horizontal-type bushing-type high temperature exhaust-heat recovery unit capable of generating saturated vapor and superheated vapor at the same time

A waste heat recovery device and superheated steam technology, which is applied in the directions of steam superheating, steam generation, lighting and heating equipment, etc., can solve the problems of high manufacturing cost and difficulty, high requirements for connecting pipes and materials for recovery devices, and achieves easy access and low cost. , the effect of reducing the difficulty of manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following structural drawings and embodiments further illustrate the present invention.

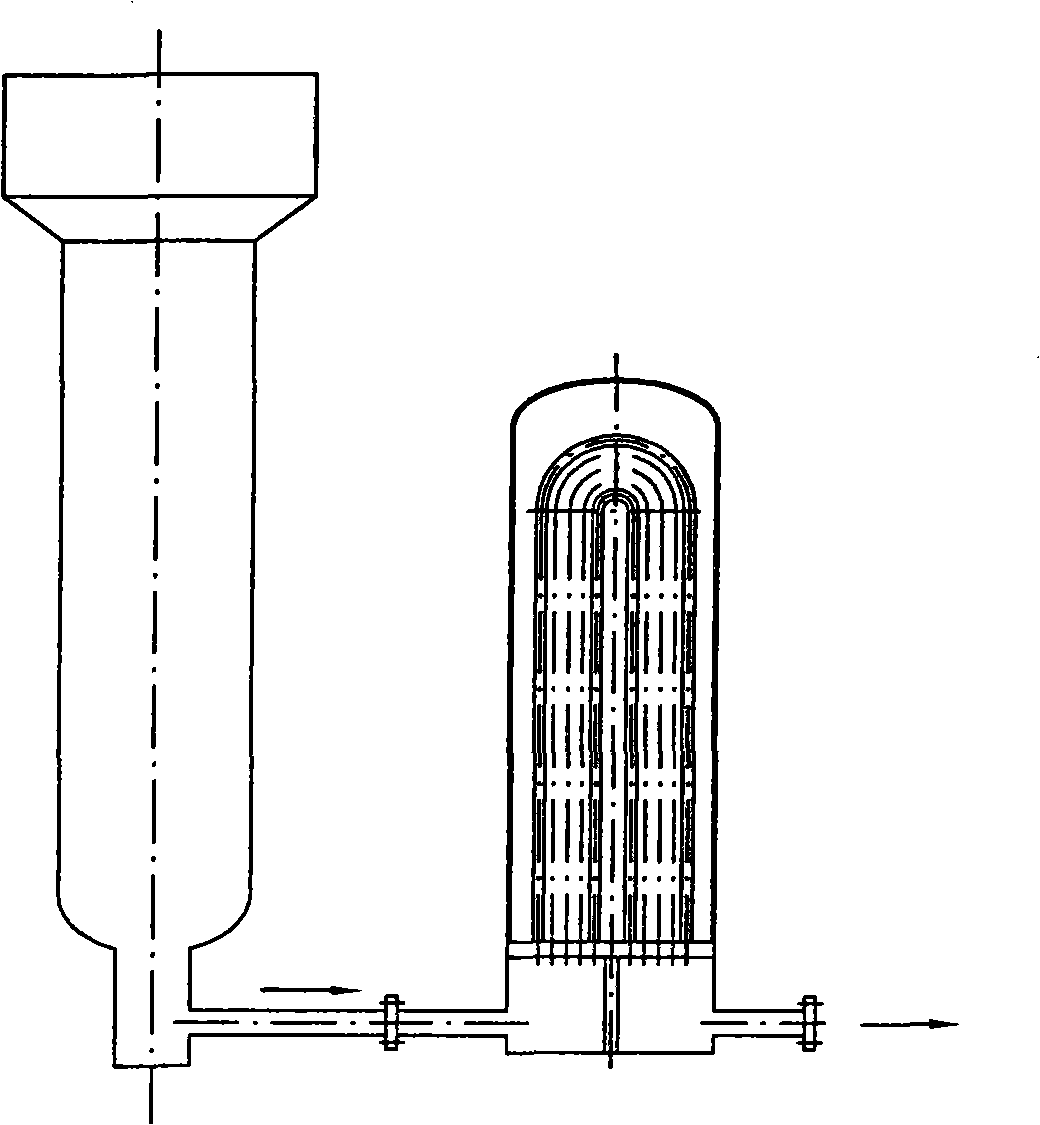

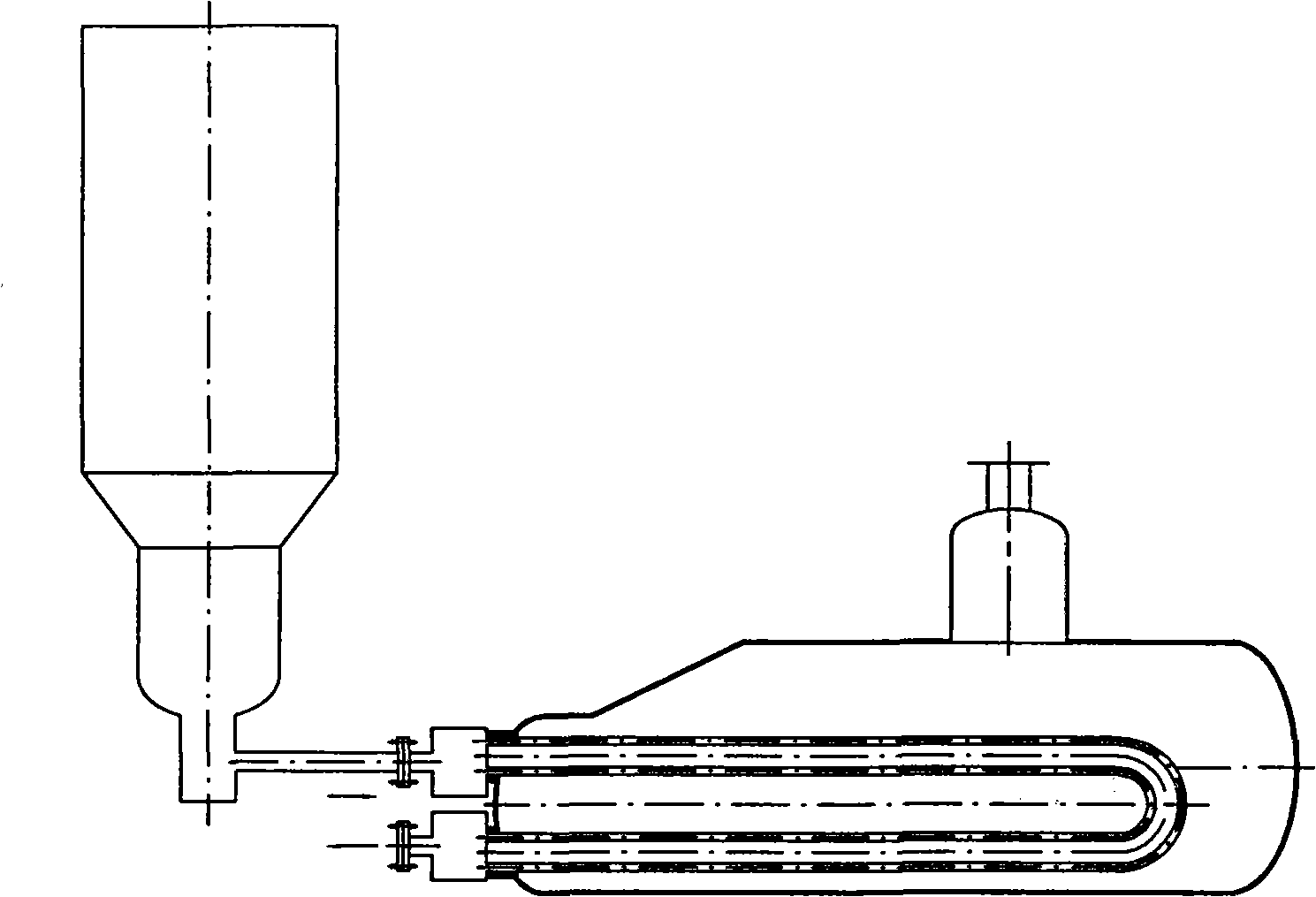

[0031] Such as Figure 4 , Figure 5 shown.

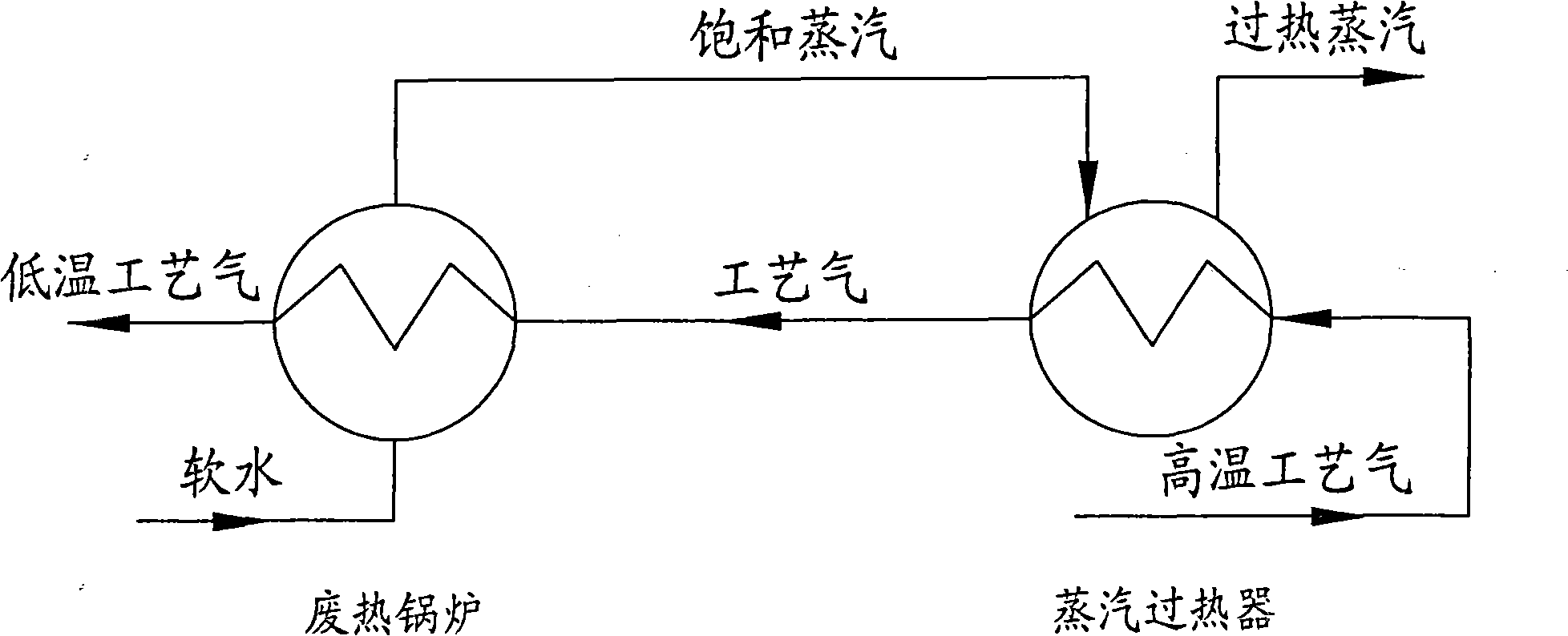

[0032] A horizontal sleeve-type high-temperature waste heat recovery device capable of simultaneously generating saturated steam and superheated steam, including a high-temperature connecting pipe 3, a high-pressure outer header 5, a high-temperature inner header 7, a boiler outer cylinder 8 and a casing composed of The waste heat boiler tube bundle 13, the high-pressure external header 5 are connected to the reactor 1 through the connecting flange 4, the high-temperature internal header 7 is installed in the high-pressure external header 5, and the inlet end of the high-temperature internal header 7 is connected to one end of the high-temperature connecting pipe 3 The other end of the high-temperature connecting pipe 3 extends into the reactor 1; the heat exchange part of the waste heat boiler tube bundle 13 is installed in the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com