Optical fiber connector and assembly method thereof

An optical fiber connector and assembly method technology, which is applied in the coupling of optical waveguides and other directions, and can solve the problems of small dispensing space and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

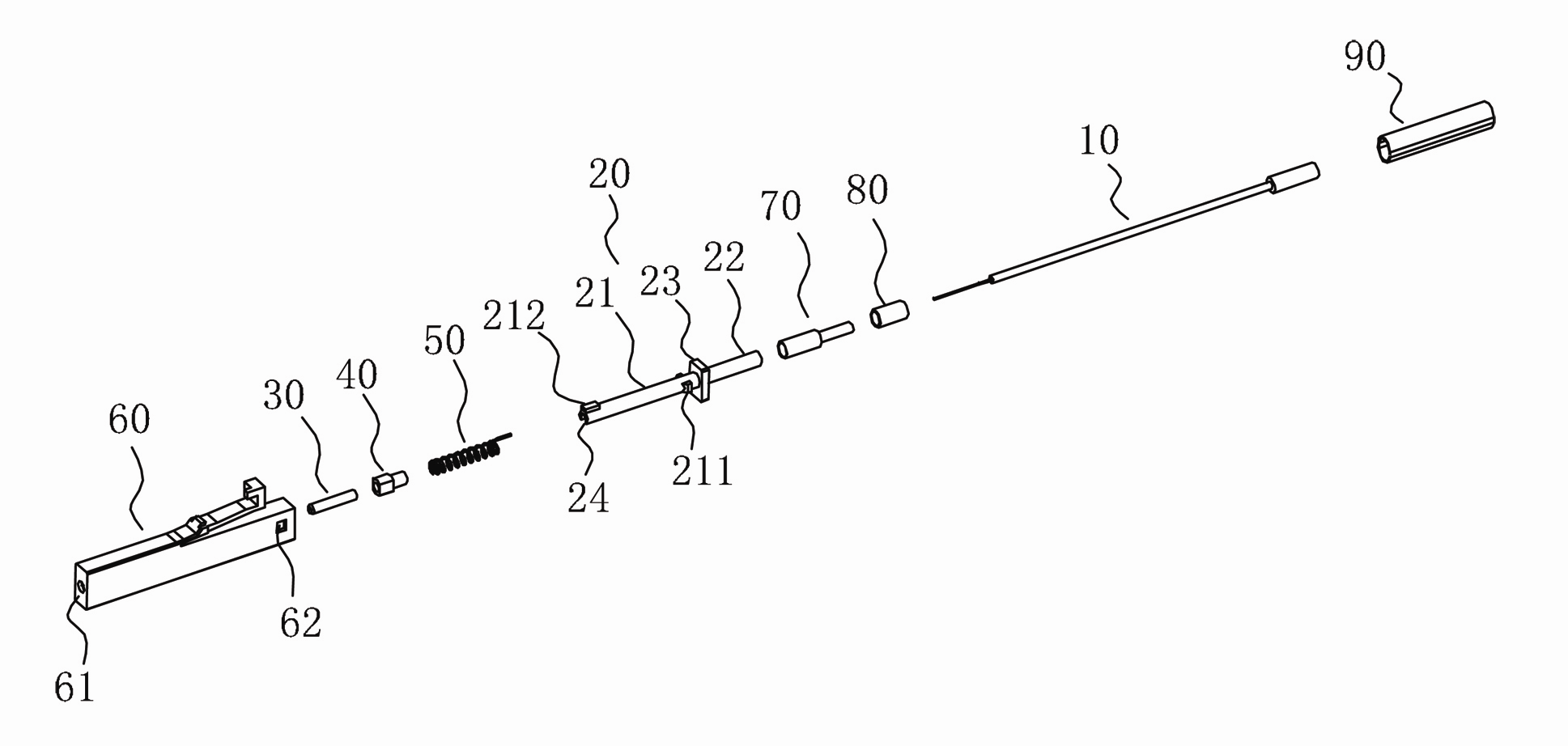

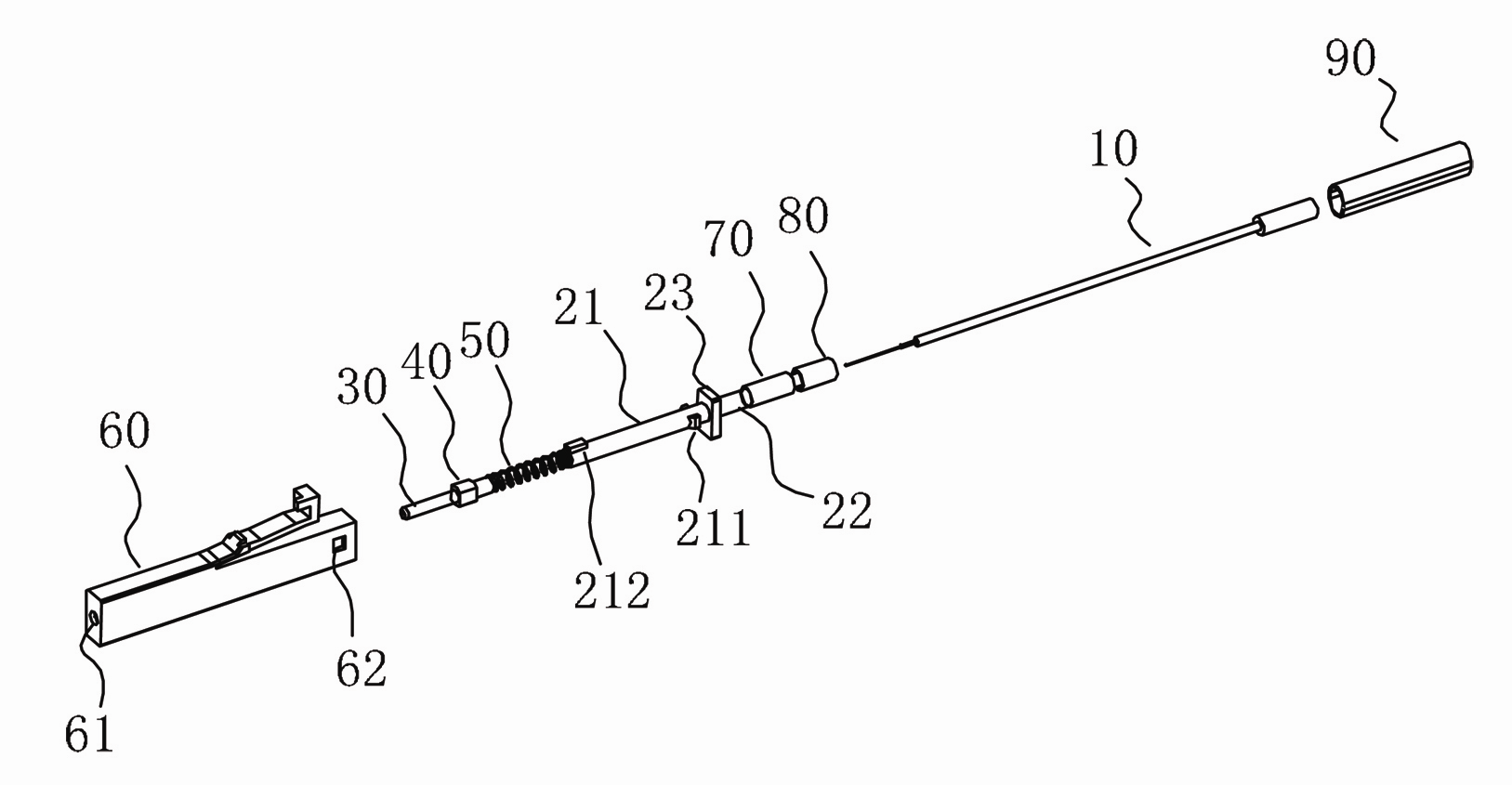

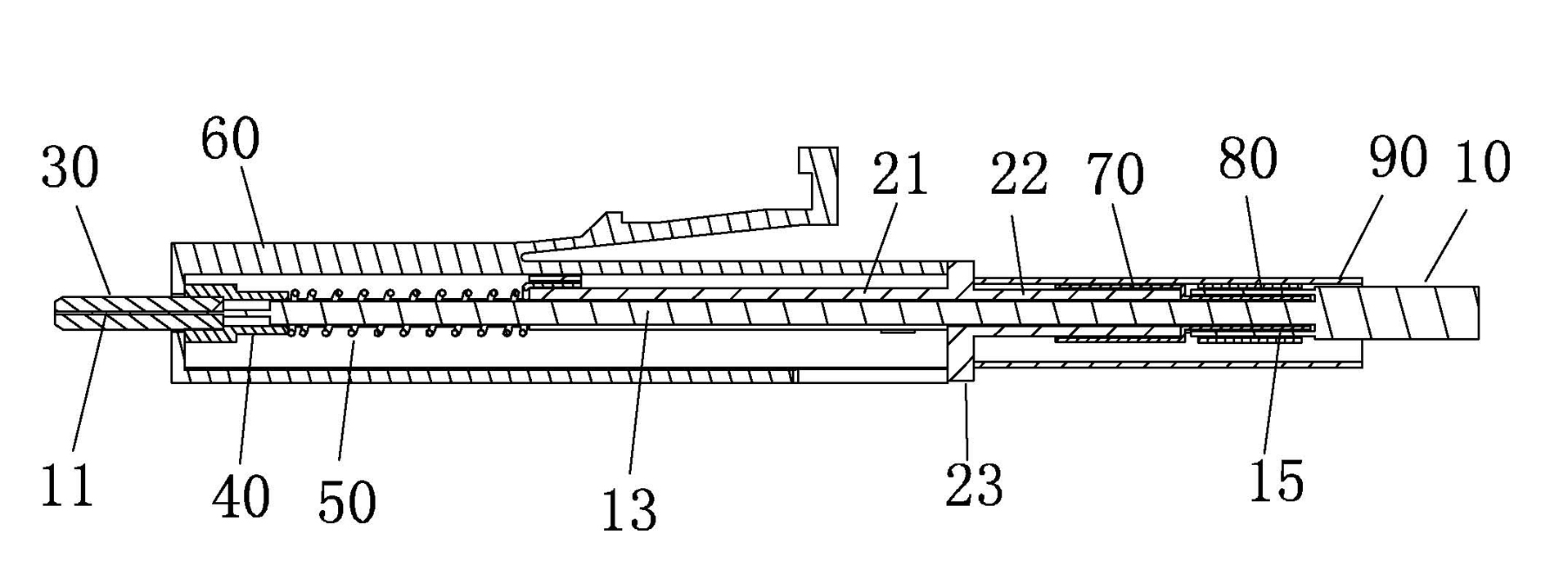

[0029] Figure 1-7 In the illustrated embodiment, an optical fiber connector of the present invention includes: a stopper seat 20, a spring 50, a ceramic ferrule tailstock 40, a ceramic ferrule 30, and an inner frame sleeve 60, and the optical fiber 10 is connected from the inside to the outside The fiber core 11, the coating layer 12, the tight sleeve layer 13, the spun fiber layer 14, and the protective jacket 15 are sequentially covered; The stop baffle 23 between the sleeve and the rear connecting sleeve is integrally formed; the inner frame sleeve 60 has a cavity inside, one end of the inner frame sleeve is open, and the other end of the inner frame sleeve is provided with a hole for the ceramic ferrule 30 to pass through. Through hole 61; when assembling, first insert one end of the ceramic ferrule 30 into the front port of the ceramic ferrule tailstock 40, then add fixing glue in the rear port of the ceramic ferrule tailstock 40, and then peel off the optical fiber 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com