Hydraulic control device for lockup clutch

A lock-up clutch, oil pressure control technology, applied in transmission, transmission control, fluid transmission, etc., can solve the problems of bubble retention, vehicle driving performance damage, insufficient transmission torque, etc., to restrain transmission Reduced torque and improved drive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention will be described in detail below with reference to the drawings.

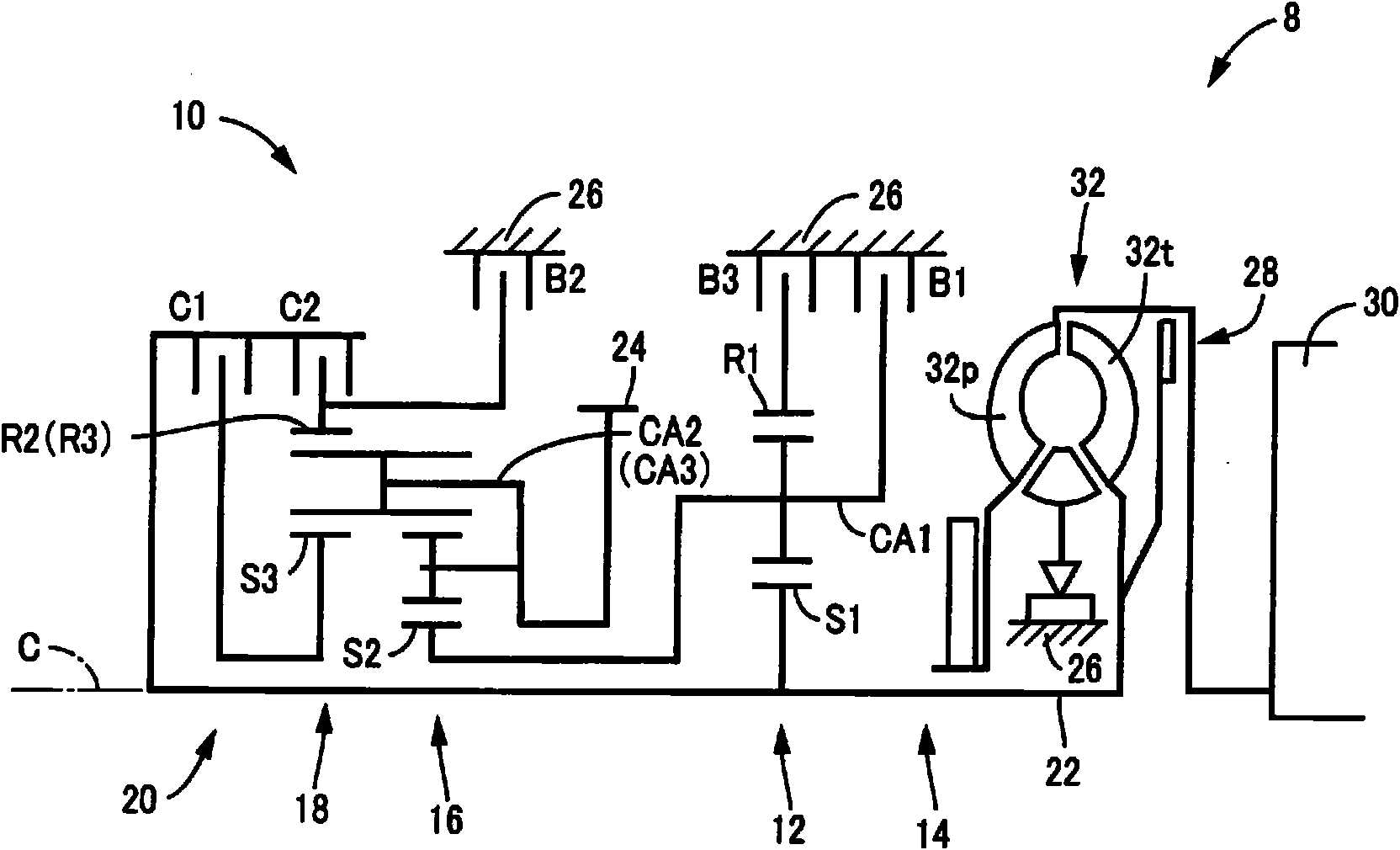

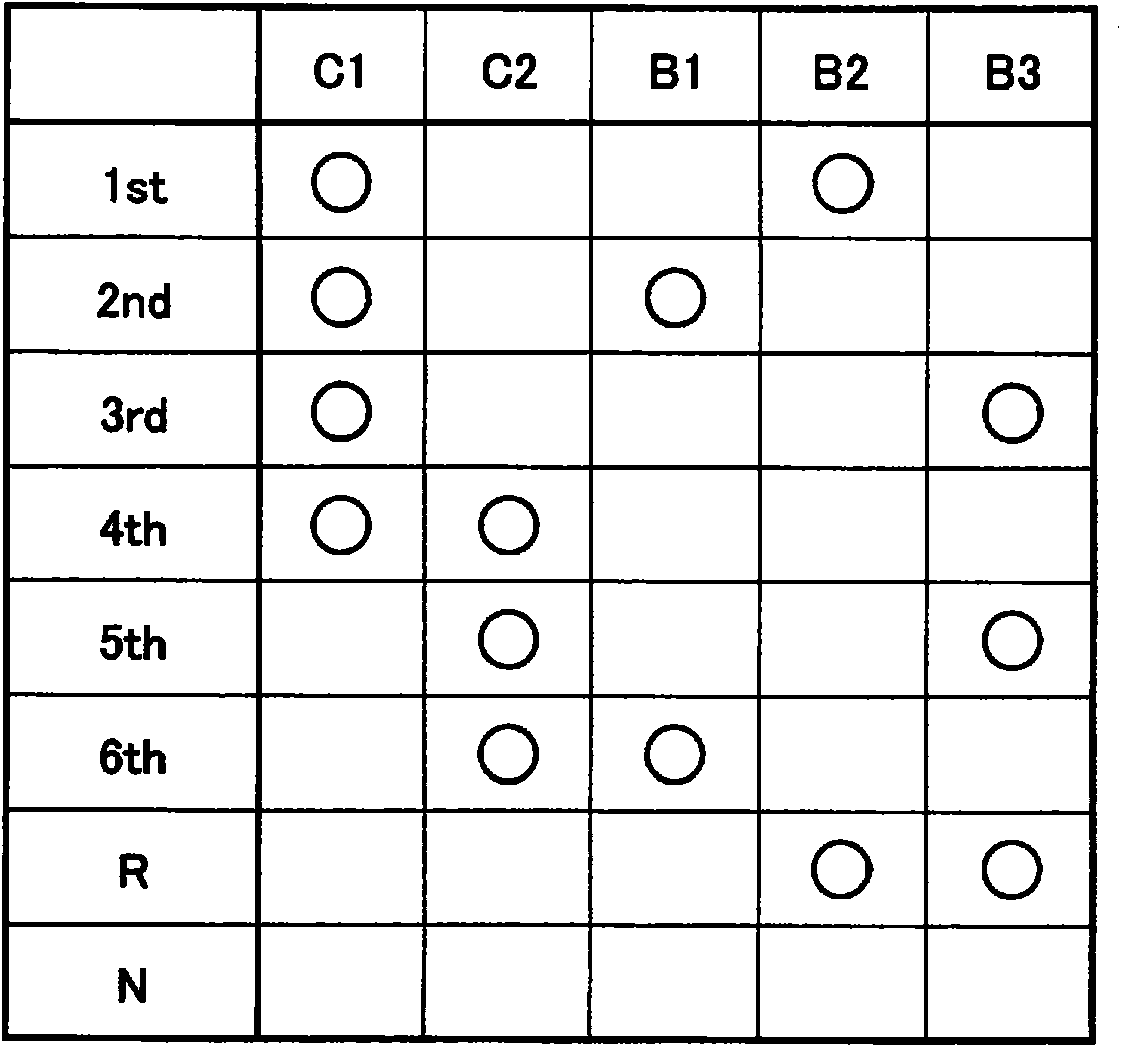

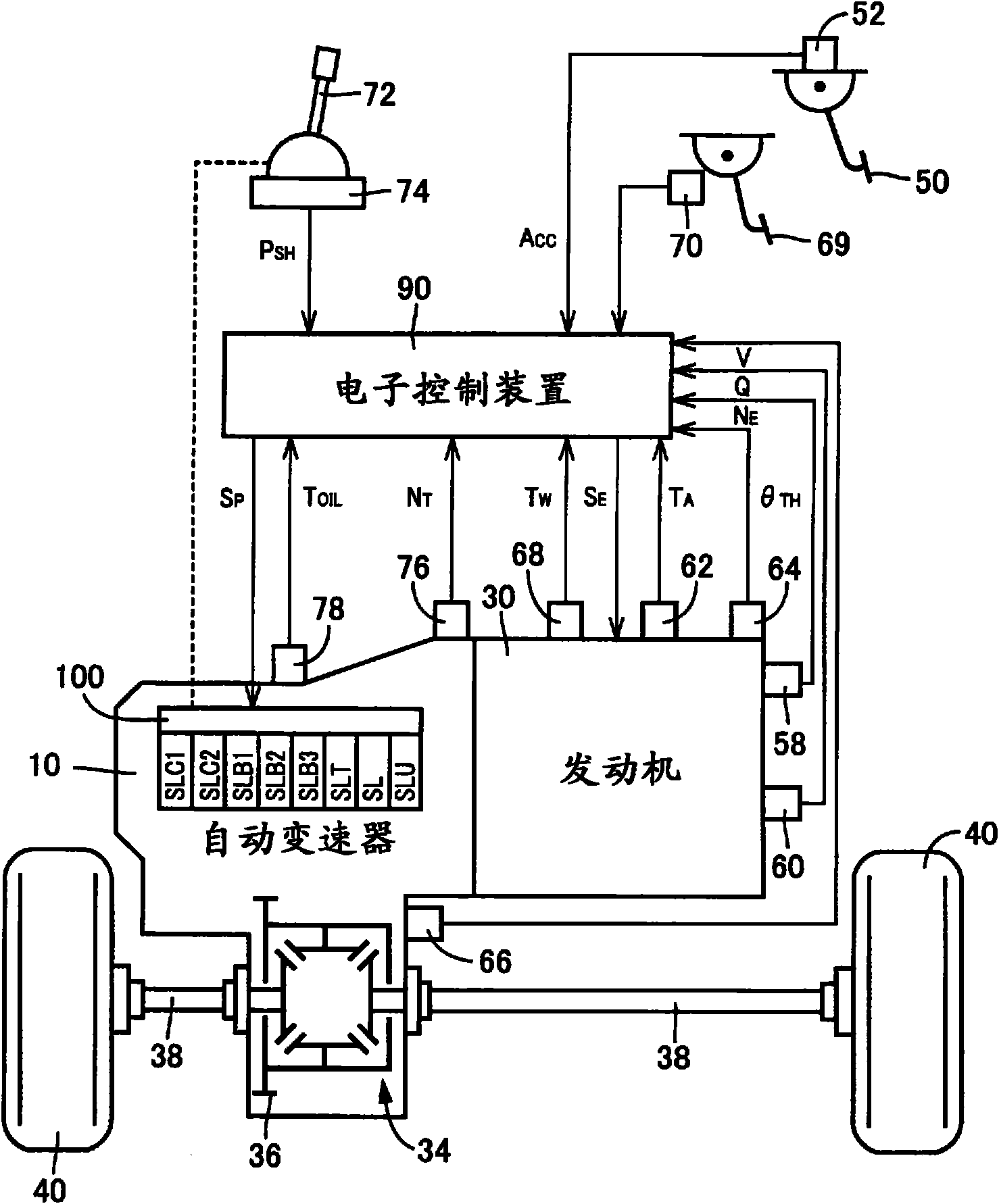

[0044] figure 1 It is a configuration diagram illustrating a schematic configuration of a vehicle transmission 8 to which the present invention is preferably applied. The vehicle transmission 8 is preferably used in an FF vehicle mounted in the left-right direction (horizontal position) of the vehicle, and the output of the engine 30 is transmitted from the torque converter 32 and the automatic transmission 10 through image 3 The illustrated differential gear unit 34 and a pair of axle shafts 38 transmit to a pair of drive wheels 40 . The engine 30 is a driving force source and is composed of an internal combustion engine such as a gasoline engine or a diesel engine. Furthermore, the torque converter 32 is a fluid transmission device that has a lock-up clutch 28 that connects a pump impeller blade 32p and a turbine blade 32t integrally or in a predetermined relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com